oldestof11

Drag racer

So I have been working on this one for over a year. As I replaced parts, I upgraded where I could. It is a 1993 D250 club cab 2wd. Only saving graces are the working AC, captains chairs, and a Posi-lok rear end.

The name came from my daughter who is always asking to "ride in daddy's truck?"

First thing to do was a transmission fluid filter and change. Fluid was darker and had some, what I considered 200k mile normal, fuzzy magnet. I adjusted bands and turned line pressure up by 3 full turns. Didn't do much but the shifts felt firmer. Went to the track and ran 17.7 seconds. Not bad for an all stock 1st gen. I also went to Byron Dragway's spring diesel event. Got 2nd in the ET bracket racing. Final pass my drivers side soft brake line sprung a leak. Fixed that. Yes, I oiled down the track and I offered to help clean it.

The rear main seal failed so Schrowang and I dropped the trans and replaced it. When we buttoned it back up, I added Travellers Tractor Transmission Hydraulic oil. Should have done that a long time ago. I went from 16mpg average to 19. I went back to the track, ran a 16.9 and this time, I had NO overdrive. Come to find out my TPS was going out and WOT it wouldn't shift. I ran most of the summer like this.

Then come end of August, with a bonus I got, I bought some things. I called up Eric Gilbert at The Hungry Diesel and ordered one of his custom piston lift pumps and Isspro boost and pyro gauges. Through some forum searching, I acquired a set of 370's for $100. I also bought a HE351 from Mark Nixon. Only thing that got put on right away was the lift pump as my stocker sprung a leak.

On the way home from work one day, I heard the tell tale sign noise of a turbo going. Once it built 2-3 psi, it sounded like a dremel. Off came the H1C, on went the HE351. Stock injectors and a poorly wired shut gate netted me 28psi of boost. I ran this setup until late January. Thanks again to Schrowang and his amazing welding skills to build me a HE351-intercooler charge pipe.

Then I started having some starting issues. I called up Chris Luttrel at Ducky Fuel Injection and he put the 370 nozzles on to 1st gen bodies. Good thing I let him as 1 injector was toast and 2 were wore out. Got them back and installed them. Since it was winter, I didn't think much of the hard starts. That came to bite me in the azz later.

With that setup, I only hit 1300* EGT and 30psi of boost. Thinking something was wrong, found I wasn't getting full throttle travel. Fixed that and my EGT's became my RPM gauge! :hehe: I could peg my 1600* gauge by 45mph.

Found my wired gate wasn't working right. So I cut up a HX52 wastegate and bracket to install on my truck. Wastegate opens at 30psi on the dot without the solenoid being energized. I haven't wired that up yet as I am afraid of a blown head gasket or busting something else. This slowed the pegging of the EGT gauge to 65mph.

Then a month ago I dropped the truck 2" front and rear.

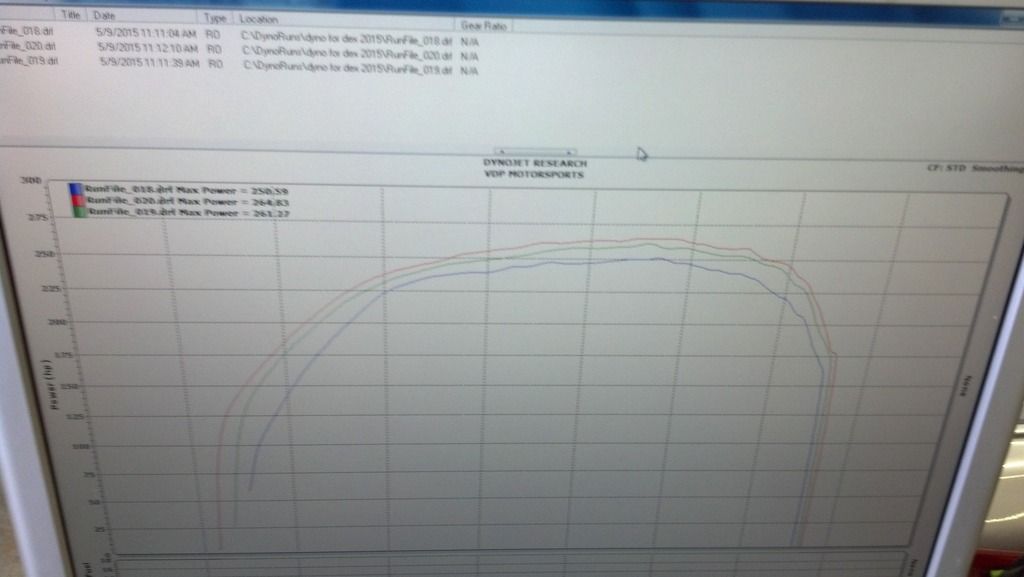

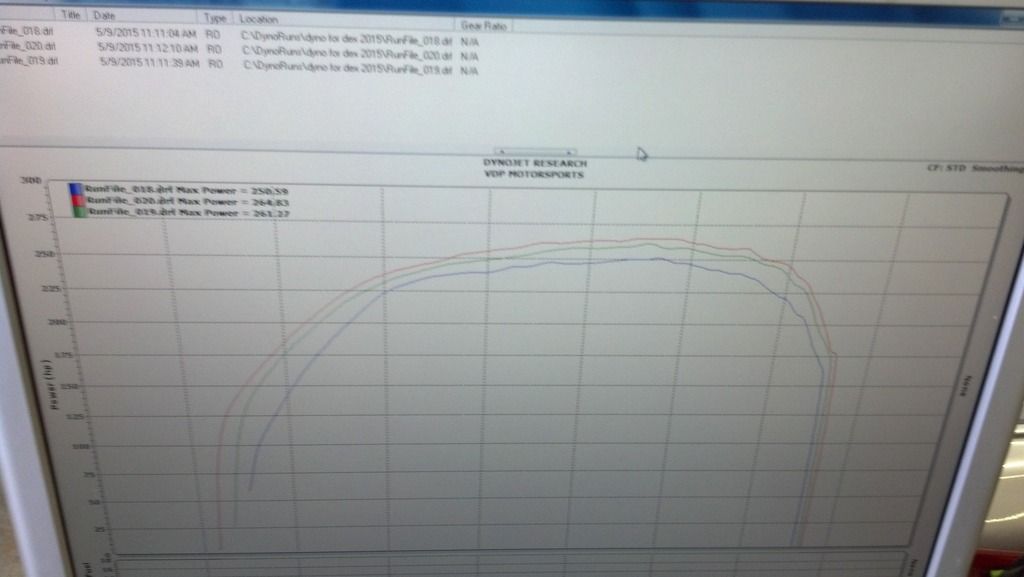

Ran down to Dyno for Dex and put down 264hp.

Last summer I bought some used but good shape 33x16.5x15 MT Drag ET's for $50. I finally spent the money on a set of steel wheels and got them installed.

And this is where I am at. I found a boost leak from the AFC reference line and replaced that with AFC Live. Then I finally found my hard start/loping issue I have been chasing since March. My timing was too low. Added more timing and now the EGT's are more manageable. Now pegging at 80mph than 65. Also with the AFC line closed, I still hit 18psi and 1200* on a WOT run to 75mph.

Things to do yet this year: install the 3800 gov spring, build drive line loops, and build a set of traction bars.

I know I have a 2wd suspension tuning post but this is to document and get feed back on my whole build.

The name came from my daughter who is always asking to "ride in daddy's truck?"

First thing to do was a transmission fluid filter and change. Fluid was darker and had some, what I considered 200k mile normal, fuzzy magnet. I adjusted bands and turned line pressure up by 3 full turns. Didn't do much but the shifts felt firmer. Went to the track and ran 17.7 seconds. Not bad for an all stock 1st gen. I also went to Byron Dragway's spring diesel event. Got 2nd in the ET bracket racing. Final pass my drivers side soft brake line sprung a leak. Fixed that. Yes, I oiled down the track and I offered to help clean it.

The rear main seal failed so Schrowang and I dropped the trans and replaced it. When we buttoned it back up, I added Travellers Tractor Transmission Hydraulic oil. Should have done that a long time ago. I went from 16mpg average to 19. I went back to the track, ran a 16.9 and this time, I had NO overdrive. Come to find out my TPS was going out and WOT it wouldn't shift. I ran most of the summer like this.

Then come end of August, with a bonus I got, I bought some things. I called up Eric Gilbert at The Hungry Diesel and ordered one of his custom piston lift pumps and Isspro boost and pyro gauges. Through some forum searching, I acquired a set of 370's for $100. I also bought a HE351 from Mark Nixon. Only thing that got put on right away was the lift pump as my stocker sprung a leak.

On the way home from work one day, I heard the tell tale sign noise of a turbo going. Once it built 2-3 psi, it sounded like a dremel. Off came the H1C, on went the HE351. Stock injectors and a poorly wired shut gate netted me 28psi of boost. I ran this setup until late January. Thanks again to Schrowang and his amazing welding skills to build me a HE351-intercooler charge pipe.

Then I started having some starting issues. I called up Chris Luttrel at Ducky Fuel Injection and he put the 370 nozzles on to 1st gen bodies. Good thing I let him as 1 injector was toast and 2 were wore out. Got them back and installed them. Since it was winter, I didn't think much of the hard starts. That came to bite me in the azz later.

With that setup, I only hit 1300* EGT and 30psi of boost. Thinking something was wrong, found I wasn't getting full throttle travel. Fixed that and my EGT's became my RPM gauge! :hehe: I could peg my 1600* gauge by 45mph.

Found my wired gate wasn't working right. So I cut up a HX52 wastegate and bracket to install on my truck. Wastegate opens at 30psi on the dot without the solenoid being energized. I haven't wired that up yet as I am afraid of a blown head gasket or busting something else. This slowed the pegging of the EGT gauge to 65mph.

Then a month ago I dropped the truck 2" front and rear.

Ran down to Dyno for Dex and put down 264hp.

Last summer I bought some used but good shape 33x16.5x15 MT Drag ET's for $50. I finally spent the money on a set of steel wheels and got them installed.

And this is where I am at. I found a boost leak from the AFC reference line and replaced that with AFC Live. Then I finally found my hard start/loping issue I have been chasing since March. My timing was too low. Added more timing and now the EGT's are more manageable. Now pegging at 80mph than 65. Also with the AFC line closed, I still hit 18psi and 1200* on a WOT run to 75mph.

Things to do yet this year: install the 3800 gov spring, build drive line loops, and build a set of traction bars.

I know I have a 2wd suspension tuning post but this is to document and get feed back on my whole build.

Last edited: