A couple notes from someone that has more arc on hours than I care to admit:

The irony of welding is: The better you get at it, the worse the equipment can be and get away with: In a pinch three 12v car batteries in series and some 6010 rod can get an experienced welder through just about any steel fab job.

-As was mentioned always buy more amps than you think you will need. IMHO 200 is the absolute minimum for aluminum, and even then you will find yourself either wanting a helium mix or standing on the pedal full time.

-Watercooled torches are worth it if you are going to weld a lot of aluminum, or you get good at wearing a fab glove on your torch hand and holding it on the cable not even the handle.

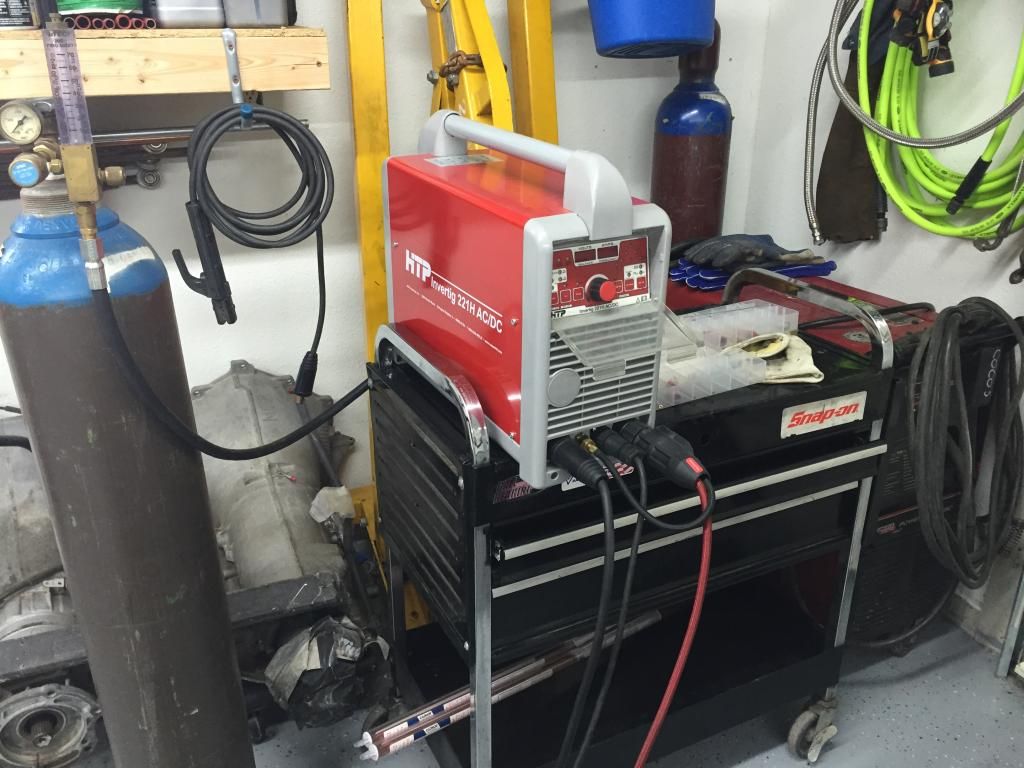

-Inverter technology offers benefits beyond weight, such as frequency control, wave shape, pulse without add on boards. But weight is worth it alone.

-You don't NEED AC to weld aluminum, you can run a helium mix, BUT and this is a BIG BUT: It sure makes your life a lot easier to have AC for welding aluminum. You can get away with welding aluminum without perfect prep, tacking is easier, everything is easier.

-If you buy and older non high frequency machine, do a lot of practice with your scratch starts before welding anything critical as it is very easy to contaminate your tungston on a scratch start. HF is really worth it.

-Learn to grind your tungston correctly for the style of machine you have. One more advantage of an inverter machine. You grind the tungston the same for aluminum as steel and it gives you far superior arc control vs balled tungston.

-Gas lenses are worth the money, learn to love them. They will get you out of a lot of jams that would other wise need back purging or a box, and make your welds prettier as an added bonus.

-Chineese welders are hit and miss, I have welded with a few that seemed to be okay at mid level amps. Low level and they had horrible arc stability and high amps, they just didn't put out the power. It is also not uncommon to go into an old welding shop and still see old Miller and Lincoln welders that are still in use. Like anything quality comes at a price.