Big Blue24

Comp Diesel Sponsor

I reread my post. It was poorly worded and frankly not all that useful. I guess I was just surprised that a 180 pump at ~24* with 5x14 was maxed at 500hp worth of fuel. Im curious if the AFC live was tuned for max power or some kind of EGT/smoke compromise.

BTW I'm seriously looking at getting this turbo from you guys. Hence why I ask so many questions. It does look like it hits a sweet spot on these trucks. Anything more and I'll need billet input/output shafts on the trans but it cheap enough that it's not far off a set of budget built compounds. Just alot easier to set up.

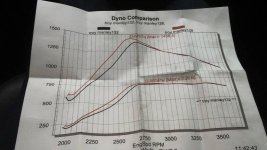

We played around with the fueling via AFC LIVE and there was very little difference other than more smoke and higher EGT going from 85% of max rack travel to 100% rack travel. This pump has never been benched so we don't know what it flows. Also, keep in mind, the internet is full of inflated "corrected" dyno numbers, so much so that expectations are set a little too high for most turbo/fueling setups. This truck at a "national dyno event" would probably make between 550HP and 600HP. At our shop 5700', uncorrected, on our Mustang Dyno, it did between 490 HP and 508 HP on multiple runs.

The timing seems high for a street truck? I'm looking at going up in power on my dd. I'm send my pump to Seth to go over an do some minor tuning. What loss would be had running a lower 17 timing? Is the 24 gonna harm the motor? Do you have a video of what the power is around 1800? Also when the turbo starts to come on compared to stock? I'm contemplating going budget twins but this does look appealing. does the .70 cause high drive pressures?

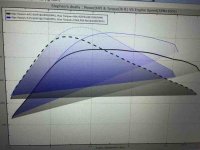

This truck came into our shop with the timing set to 24*, it's an Arizona truck that never deals with cold weather starts. It has a fresh shortblock with wide 155* bowl pistons and is equipped with 155* spray pattern injectors. The pattern hits in the bowl as designed, and the truck runs extremely well. Based on the fact that there are factory Marine applications with this much timing with a similar bowl and injector setup, no 24* is not too much for this truck and we don't want the higher EGT and power loss that would come from dropping the timing to 17* on this setup. We don't have a video of power at 1800 RPM, but we can load the dyno so hard, it will make full boost and 900 ft lbs at 1800 if we wanted, it would just chug and smoke heavy at 1400 rpm trying to spool against the massive load at low RPM so the dyno can be manipulated somewhat to make turbos come on earlier in the powerband than they might on the street. This turbo is definitely slower spooling than stock, but the lag to power ratio is worth it on this charger. Compared to stock, I'd say this turbo comes on about 200 to 300 rpm later. Drive pressure is largely dependent on RPM range, at normal street truck RPM ranges 3000 rpm and less, drive pressure is excellent with the .70 ar housing. If the wastegate is tuned to stay close, drive pressure rises quickly in the 3000+ RPM range. With the wastegate open, drive pressure stays in the 10 to 20 psi over boost range till 3500 rpm, that's as high as we tested on this truck/motor/cam setup, your results may vary. However, compared to stock, this turbo runs much much better in the 2500 RPM on up range. Stock HX35 turbos really struggle in the 2500+ range.

To be fair, almost any compound turbo setup is going to have a wider useful power range than a single turbo so it's not really fair to compare.... :stab: