92dak_r6

New member

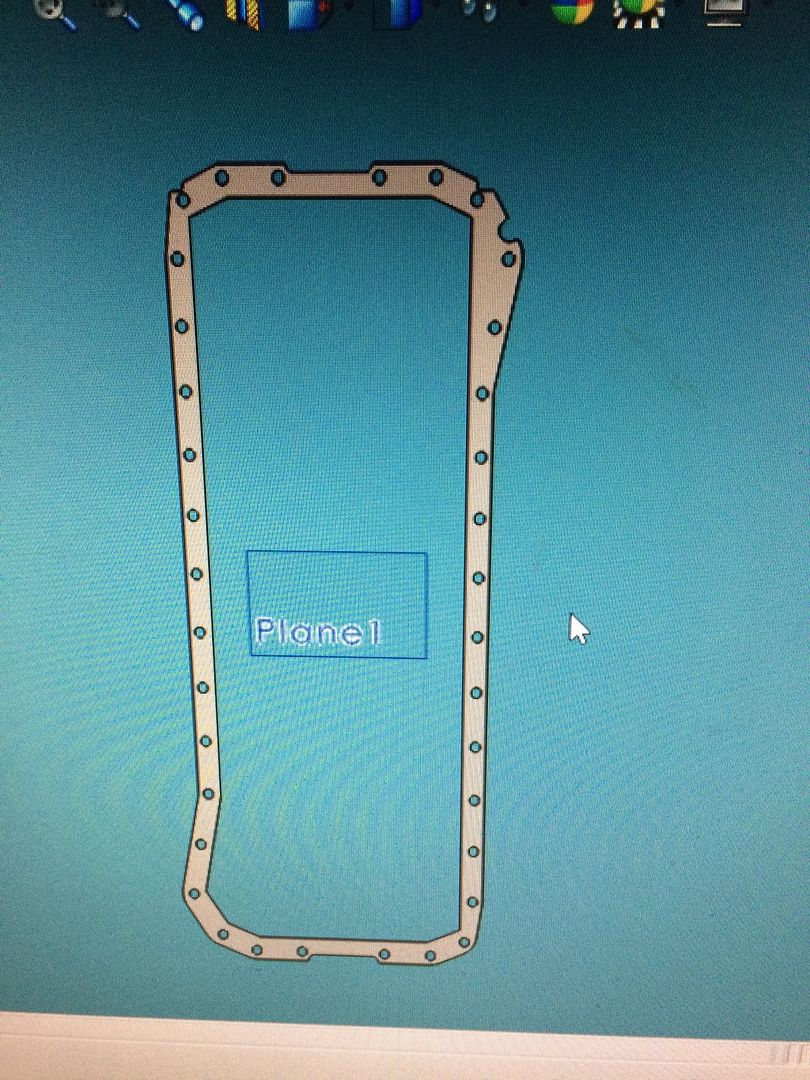

Does anyone make or know of anyone that makes an aluminum oil pan flange for a 12 valve? I'm looking to make a custom oil pan for my truck. Preferably around 3/8" thick, but at this point I guess I wont be too picky.

I have found them for common rails just not the one Im needing.

Thanks in advance.

I have found them for common rails just not the one Im needing.

Thanks in advance.

Last edited: