SCHMITTY

Not enough time

My buddy bought a 92 with a bad tranny for 3k

I just finished the 518 rebuild- pdd 425 kit, shift kit, dpc non lockup converter, servo, billet accumulator.

Truck has a 351 on it.

There's a bd 3200 gov spring in the glove box

He wants a fun street /daily driver that doesn't tow often.

Which size injectors would be on the big side for this turbo ? I'd rather not max the fuel screw out and start losing shut off solenoid tips- the owner is a fabricator/welder and may compound the 351 in he future.

I plan on bumping the timing up a little , playing with the throttle linkage, afc and a Denny t stage 2 pin

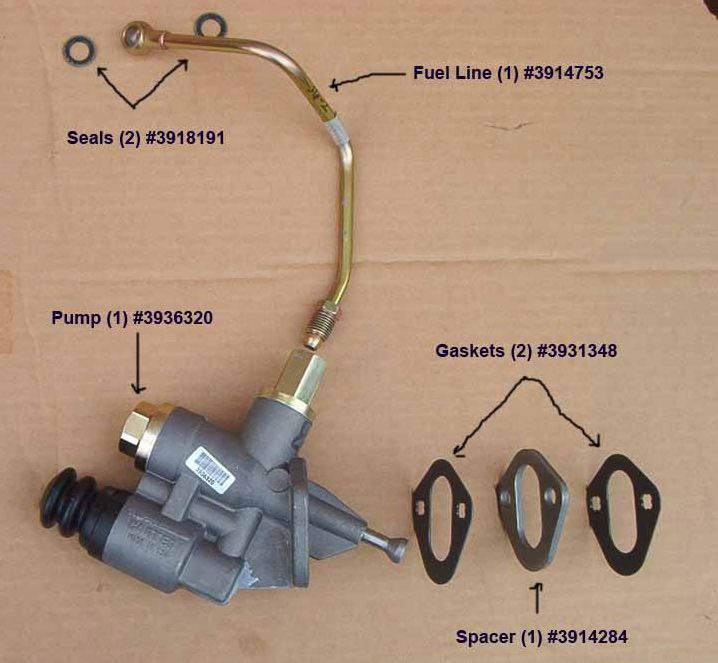

Is the hungry diesel lift pump worth it ? Or should we throw a Holley blue on ?

Gauges are on order also.

I'm more familiar with the p pump trucks

I just finished the 518 rebuild- pdd 425 kit, shift kit, dpc non lockup converter, servo, billet accumulator.

Truck has a 351 on it.

There's a bd 3200 gov spring in the glove box

He wants a fun street /daily driver that doesn't tow often.

Which size injectors would be on the big side for this turbo ? I'd rather not max the fuel screw out and start losing shut off solenoid tips- the owner is a fabricator/welder and may compound the 351 in he future.

I plan on bumping the timing up a little , playing with the throttle linkage, afc and a Denny t stage 2 pin

Is the hungry diesel lift pump worth it ? Or should we throw a Holley blue on ?

Gauges are on order also.

I'm more familiar with the p pump trucks