I just wonder how these engines can still be so fuel efficient ? Scania knows something we dont.

When is big holes and high pressure causing too strong fuel penetration which makes fuel air mixing worse ?

It got a lot to do with toothpaste and extruder honing or things with a similar result. Main thing is to get turbulence out of the hi pressure system and this already starts in the hi pressure lines all the way down to the nozzle.

It’s not only Scania, the whole industry whent bigger on injector flow from Euro 4 to Euro 5 and 6. Best example I have is the 2.8L CR from Jeep that’s made 250Hp on the old type injector. Later on we did a 2.5L CR same VM engine with latest model injectors making over 320Hp on the same ECU settings and same goes for the 3L CR Toyota engines but again a big parts has to do with the piston dome in relation to the nozzle and the correct fuel pressure plays a big role as well so end of comp temp in relation to boost pressure and MAT and very little start of injection advance so a very short delay before things will combust.

On the very hi flow injectors even a pilot injection dos not make a chance any more indicating that the fuel will generally combust with very low combustion noise and no white smoke or smell up to a 15CR. Also it has been mentioned but cannot confirm this that the swirl is taken out or down in order not to disturb the fuel spay out of the nozzle so yes low velocity fuel injection and good combustion can go hand in hand this way I think.

On the non EGR Scania Euro6 version adblue can play a big parts as well as NOX is less of a concern coming out of the engine therefore less control is needed on maintaining low combustion pressure and increasing fuel economy that is still part of the Euro6 target plan the OE has to apply to.

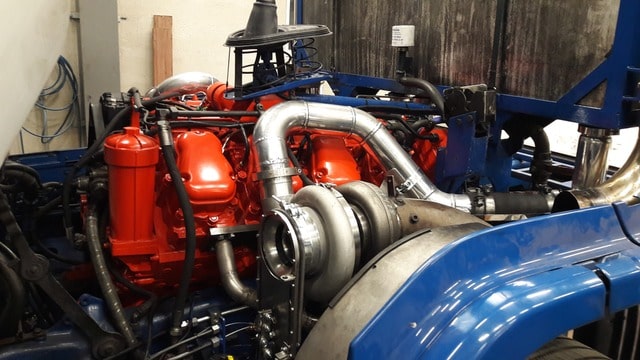

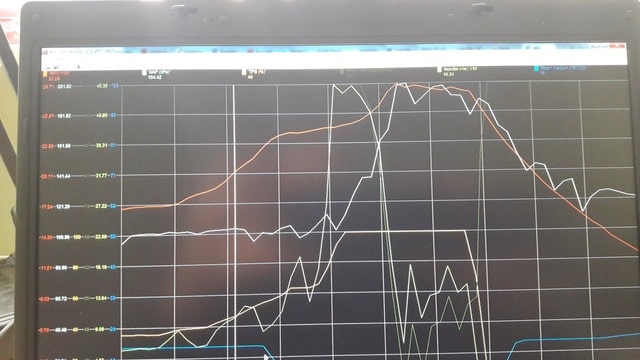

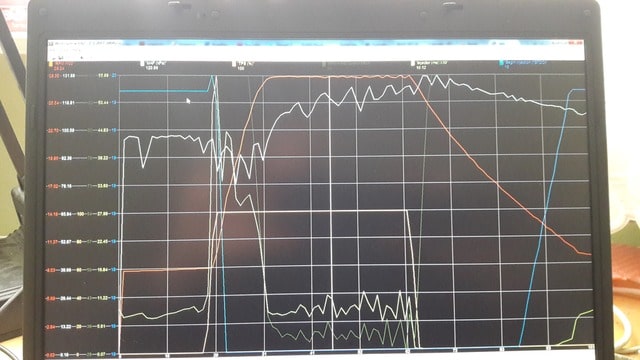

All we do on these CR engines go in fast and hard same as on a diesel pro stock engine and let the fuel regulate the combustion and inline pressure monitoring shows that peak pressure is less but pressure is maintained for a longer time therefore making more power. I think what makes the difference on start of combustion that we get small droplets of fuel and are able to keep them separated after exiting the nozzle spreading them over a large area but we must be able to ignite them before we hit the relative cold piston dome and if the bowl shape forces the air fuel mixture upward things will only ignite when boost goes up a lot and before getting white smoke and poor engine performance.

On de Scania PDE engines we discover we had some oxygen left indication that the combustion took place lower than expected and to solve this we took a CR nozzle with two rows of 4 by 4 so in total 8 holes so the cone shape spay pattern had a bigger cone angle but as we had a offset on the nozzle holes spay pattern kept clear of each other.

I also forgot to mention the needle shape plays a big role as well. Some have up to 5 different slobes depening on the needle lift/fuel pressure chaging the spay pattern/droplet size/spay velocity.

So in all things improved a lot on hardware over the years but production became extremely more difficult to maintain tolerances needed.

Fun part is if your able to delete the practical filter or bypass it same as all the after treatment stuff on hard and software big chance is fuel economy and power will improve a lot over previous fuel systems but changing injectors sometimes means changing the piston and cyl head as well as tolerances needed are getting smaller so less messing about with engine parts I think.

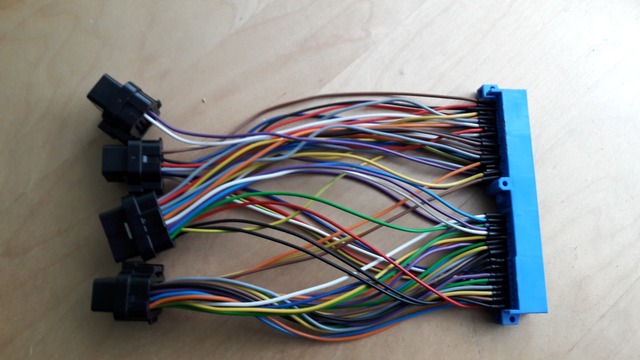

Example of a Euro 5 needle and 8 hole offset nozzle.