Financial Mistake

New member

Nvm, got the PN

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

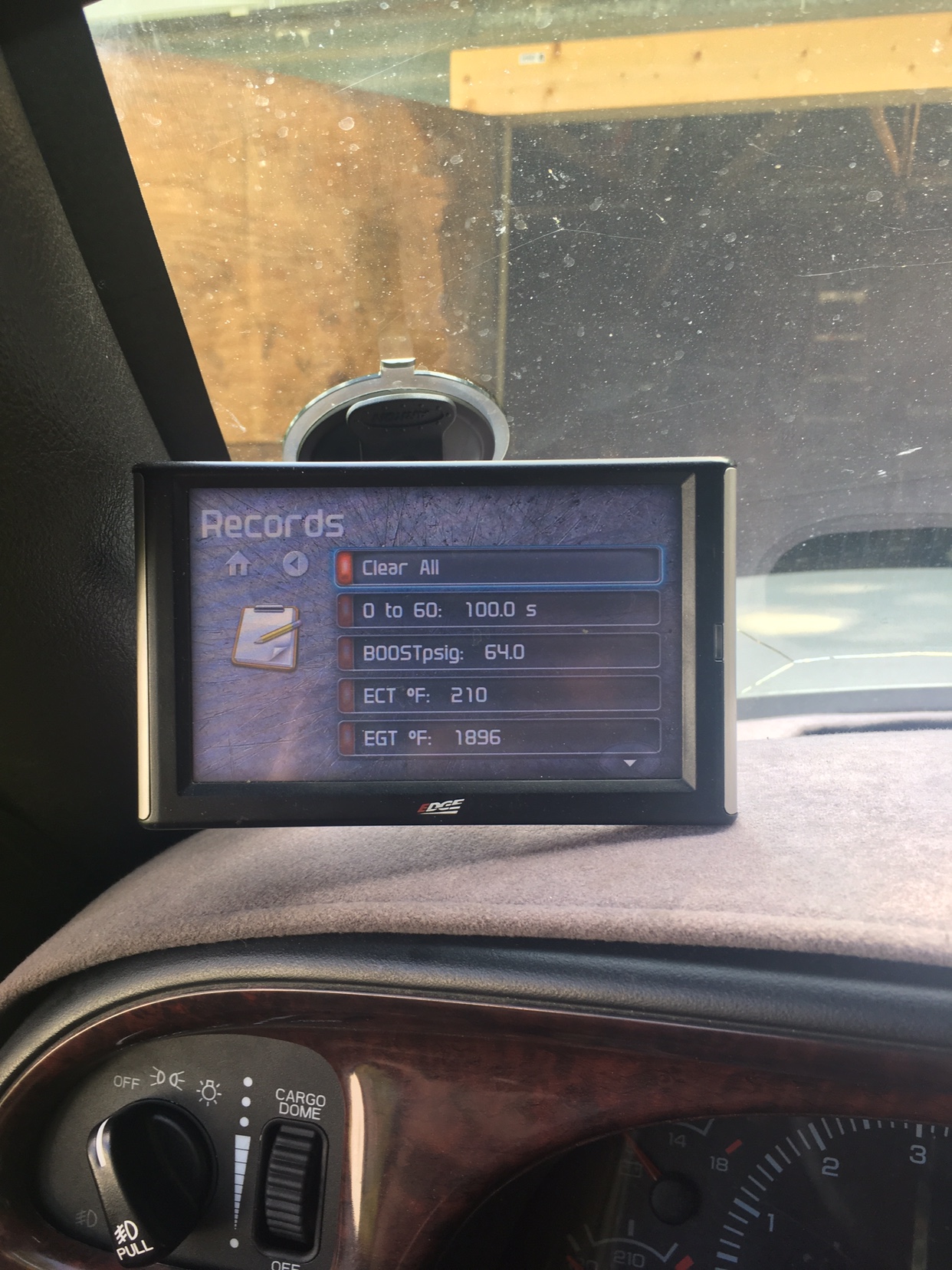

(14.5+60)/14.5= 5.13793103

I think I've come to the conclusion that I'll just go with a basic 64/480 setup, mostly because anything bigger than a 480, from what I can find, is custom machined and pulls a premium, even though is essentially a bigger inducer, with the same exducer, shoved into the same housing, so I'm not exactly sure if the gains warrant the extra cost.

Anyways, asking the peanut gallery here. Say a Sxe 64.5/73/.91 with a 50mm gate at the manifold, over a fmw 80/96/1.32 with the .66 (I think? John Deere cover, the good one.) ar housing, what would be a good 6 hole injector to pair with that.