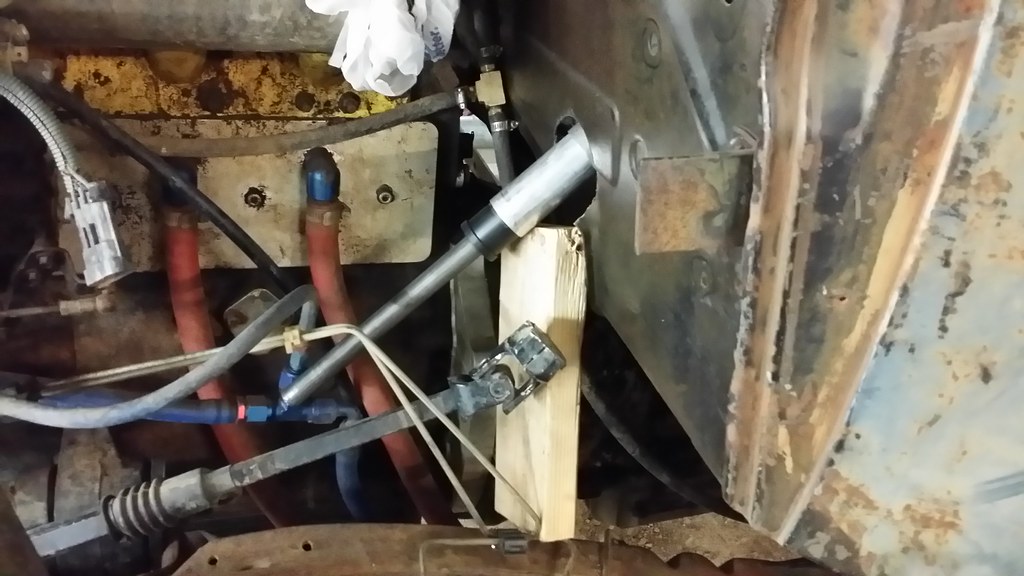

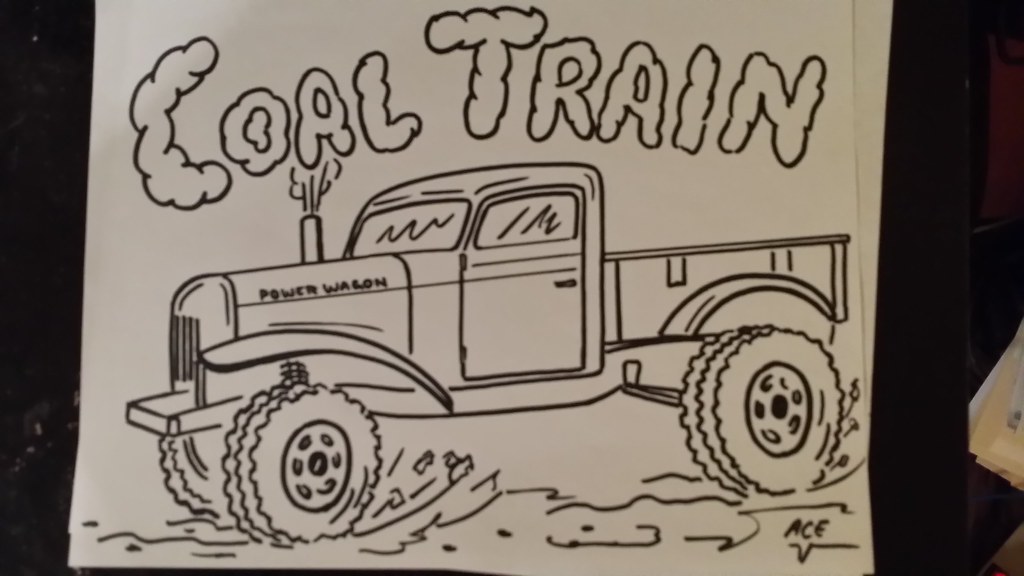

Finished getting the drivers side floor board mounted and bolted down. Bolted the transmission tunnel down as well. Had my son design the template for the passenger side of the truck starting with poster board, then he moved on to a foam board template and then we cut it out of 11 gauge sheet steel. Drilled the holes and made the slight bend in it.

Talked to the kids today and they are fine with me moving up to class 3 with the truck and so now I don't have to build a huge wildly bending exhaust pipe to make the truck legal for class 2. They just won't get to ride in my truck during the races and save some weight/room because I won't need a passenger side seat.

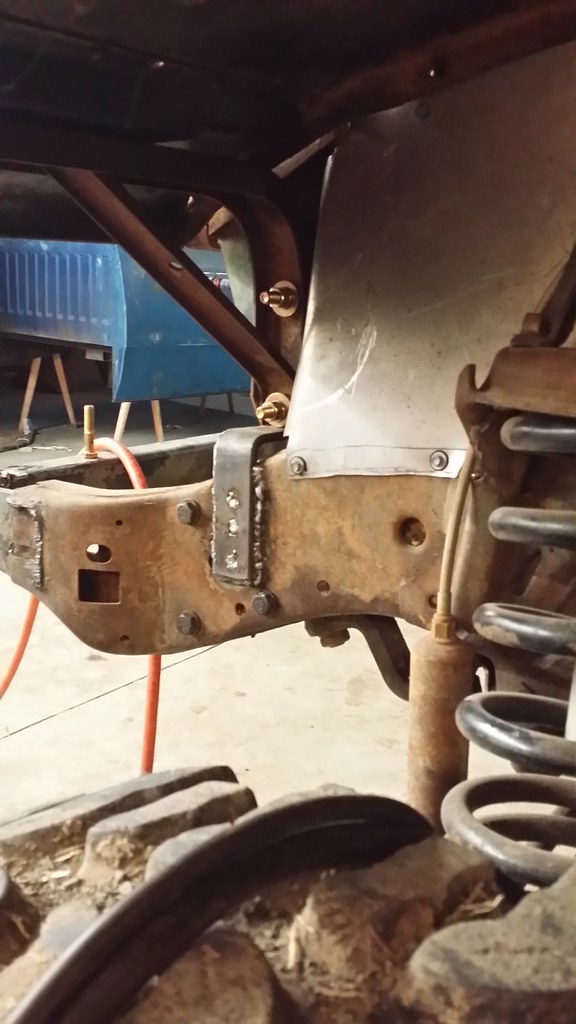

I will have to get drive shaft loops built to be legal for class 3.

Tomorrow I'm going to start building the bracket for my drivers seat. The rear fenders will be in on Tuesday and the steering column kit will be here Wednesday.

Drivers side floor board mounted

Foam template for passenger side.

Floor board marked out on the sheet steel

My son playing with the soap stone

Passenger floor board mounted.

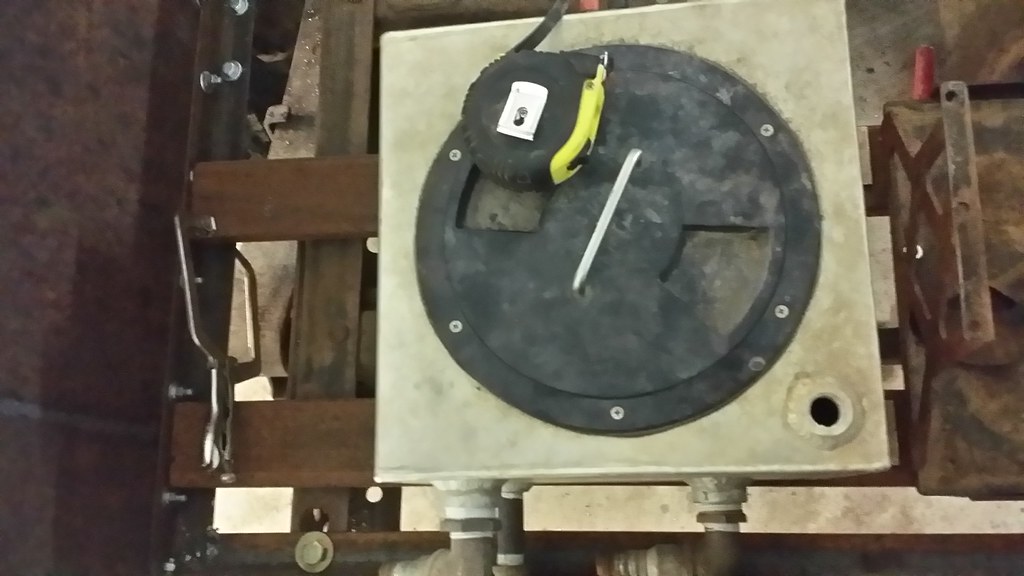

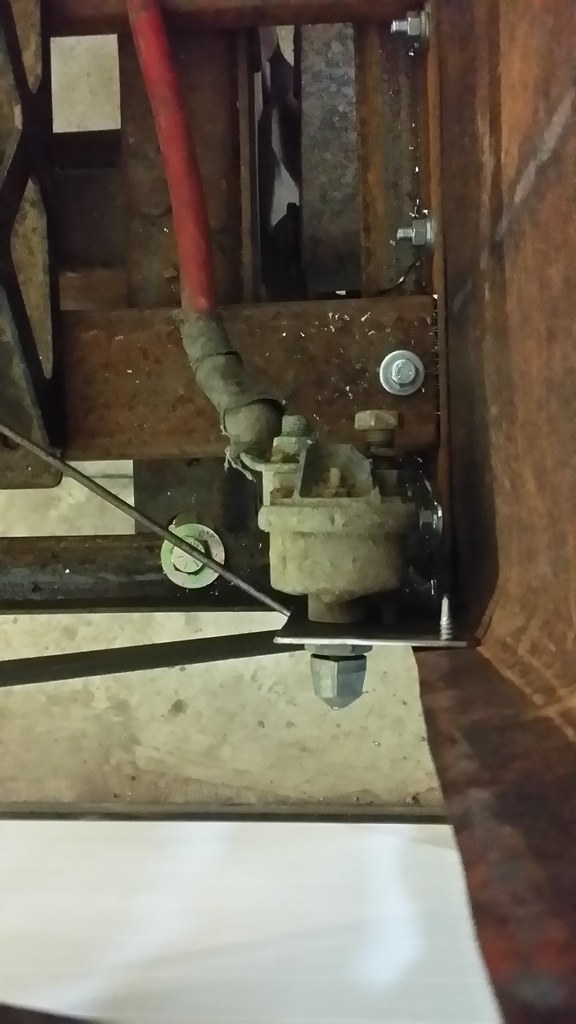

With not needing a passenger seat, I now have room in the cab for my w2a ice box.

Setting the seat up to start taking measurements for the support frame.