TruckYou

New member

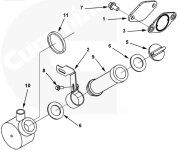

With my engine in the engine stand, IP off, and ready to swap cams, I'm starin that this Tappets cover wondering what I should do. Billet tappet covers look good, but I can only see myself doing so if I went for the Tappets cover with the AN crank Vents, to run to a catch can.

I'm debating if it's worth the money for the billet tappet cover with vent, and catch can, or if I should run a dual valve cover type crankcase vent. This is my soon to be race truck, will see high boost conditions, street able but no DD.

With the catch can, do you plumb from the can to the oil pan for recirculation?

What other options are available for the 12v

Sent from my Pixel using Tapatalk

I'm debating if it's worth the money for the billet tappet cover with vent, and catch can, or if I should run a dual valve cover type crankcase vent. This is my soon to be race truck, will see high boost conditions, street able but no DD.

With the catch can, do you plumb from the can to the oil pan for recirculation?

What other options are available for the 12v

Sent from my Pixel using Tapatalk