For me using an ECU with a defined control structure is like sitting in prison looking at the walls of limitation so yes Iím spoiled.

For example I read in one of your topics how you went along controlling two CP pumps in a sort of way and yes it works on a relative free revving engine setting RPM over to PWM on one of them controlling the other with the

PID controller.

With the nira we came along the same problem only on an engine that dos 1000hp @ 2600Rpm making the fuel pressure skyrocketing when hitting max rpm and at that time the nira was totally depending on a injector flow

map going bizarre on injector opening time staling the engine or blowing up turbochargers. Maybe times have changed on hat part but at the time we could not get it to work as the

pid controller could not follow the action on rpm governing.

We have done a V10 MAN commonrail for a customer that runs a duel controlled fuel pump and I made a cascade control strategy for it thatís also redundant as this engine normally runs on two ECU systems so everything on sensors and activates runs like twins. These are really fun jobs to do.

For commonrail we use

map prediction on fuel control so the rate of torque in/decrease is sort of pre mapped in the system to a point that you could take out sensors and still have decent engine operation. For truck or tractor pulling we use this to get spot on fuel pressure control to some extent as most of the CP series are dead slow on the activators. The biggest pump we run so far dos 250cc a second @ 1800Bar and the control on this pump is spot on and a lot better than the small CP pumps.

What you have done with placing post injections works on commonrail but we run PDE or electronic activated pump injectors that depend on camshaft lift to move the pump plunger so you do not have a whole load of fuel pumped to dump in the exhaust placing a post injection.

Second thing is that you run on diesel vapor hardly injection any fuel at hi rpm with no load so no heat to set your post injection on fire so we had to come up with something to keep max RPM as over speeding to 2901RPM means decalcification so what we do is acelerate the engine like crazy from 2800 to 2900 RPM regardless of engine load. It sounds a bit like an RPM limiter on a petrol car only a lost smarter as the ECU calculate the rate of acceleration on an engine that able to spin up 200RPM in one crank rotation.

Good example on how it works also during the run making a run of 30.17Kmh average speed

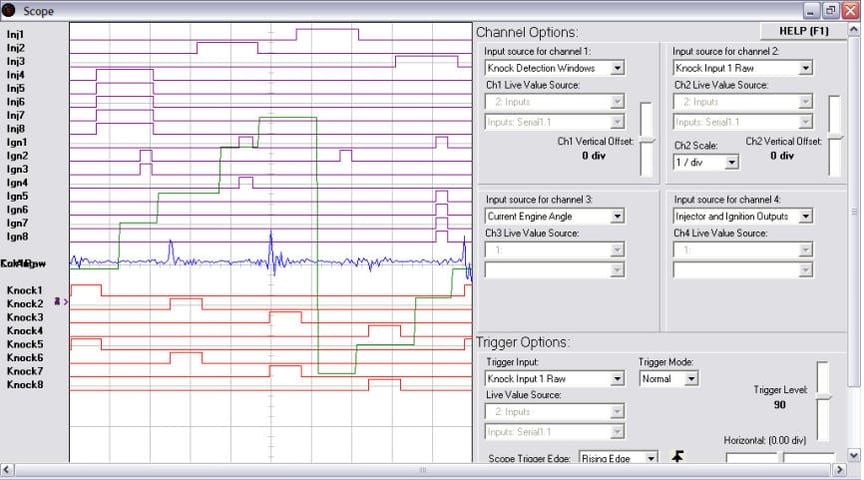

We also have an oscilloscope in the ECU to monitor things and calculations.