All of the upgraded parts have arrived so it's time to start the rebuild process.

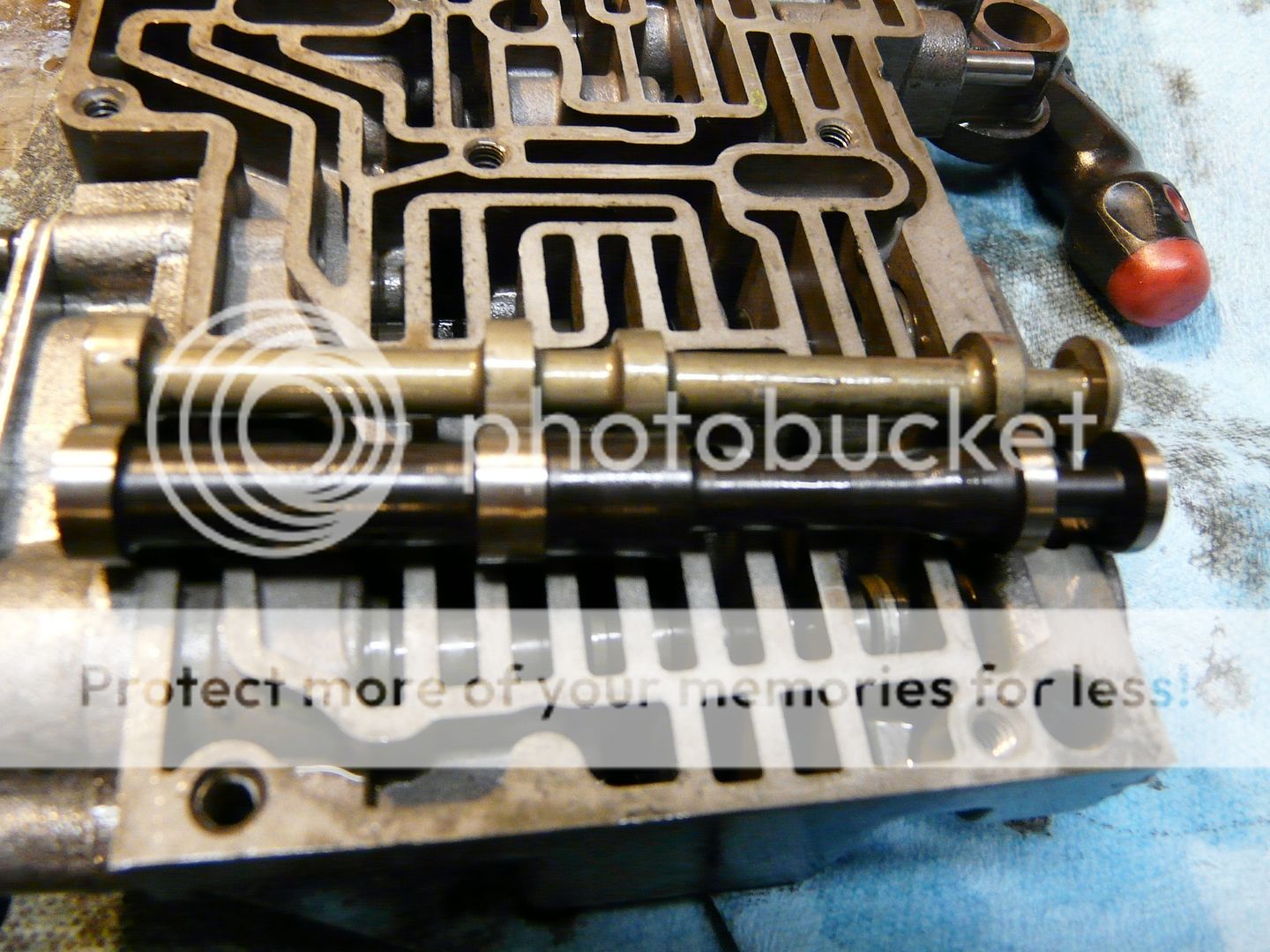

Billet Anchor, Strut, & 4.2 ratio lever, these are required to deal with the elevated line pressure in a performance transmission and are applied during 2nd gear. I've had the best luck with 2-3 shift timing using the 4.2 ratio lever vs 3.8, 4.4, or 5.0.

Sonnax upgraded low/reverse servo, I only upgrade this servo when the stock one is extremely worn, or the end user is notorious for manual 1-2 gear shifts.

Sonnax upgraded 2nd/intermediate servo cover with added seal to stop leakage and clean-up the 2-3 gear shift. I

don't use aftermarket oversized 2nd gear servos because I've never had good luck with 2-3 shift timing. Also, on a super high line pressure build, the oversized servo combined with 200+ psi line pressure can cause the billet lever to break the main transmission case or break the band.

My typical parts supplier was out of new 48re pump gears, so I sprung for this fancy teflon-coated pump gear setup.

New thrust washers for this rebuild, on a budget rebuild, many of the stock thrust washers can be reused.

This upgraded sonnax stator support bushing is a pain to install requiring patience, the freezer for the bushing, and small brake hone if it's too tight on the input shaft. For a beginner builder, I'd skip this bushing and install a stock one or reuse the old one if it's in good shape.

Stepped backing plate for (1) additional overdrive brake clutch. This 48re was rebuilt by a Dodge dealer and they removed the stepped backing plate and installed a 47re backing plate which dropped the clutch count, so now I had to buy an aftermarket 47re upgrade plate to bring it back to the stock (6) clutch overdrive setup.

Slimmer 3rd gear/direct clutch backing plate so (6) factory thickness clutches can be installed.

New 2nd gear flex band, decided to try a PATC brass mixture friction composition flex band in lieu of my standard $15 kevlar lined flex band.

Extra clutches for the over stock count clutch pack upgrades:

New sprags, for my personal transmissions I usually re-use the stock sprags since they rarely fail, but on a higher $$$ rebuild, $50 for both sprags is cheap insurance.

New bushings, many of the stock ones will be in excellent condition but on a higher $$$ non-personal rebuild, all of the main wear bushings should be replaced.

New torrington bearings for overdrive, usually the stock ones are in good shape and can be reused in a budget build. On a higher $$$ build, the $50 for new bearings is a necessary expenditure.

The low/reverse drum has a plastic thrust/retaining washer between the drum and the snap ring, this upgraded metal thrust washer is only a couple of dollars so a cheap upgrade that may not be necessary since I've never seen the plastic part fail.

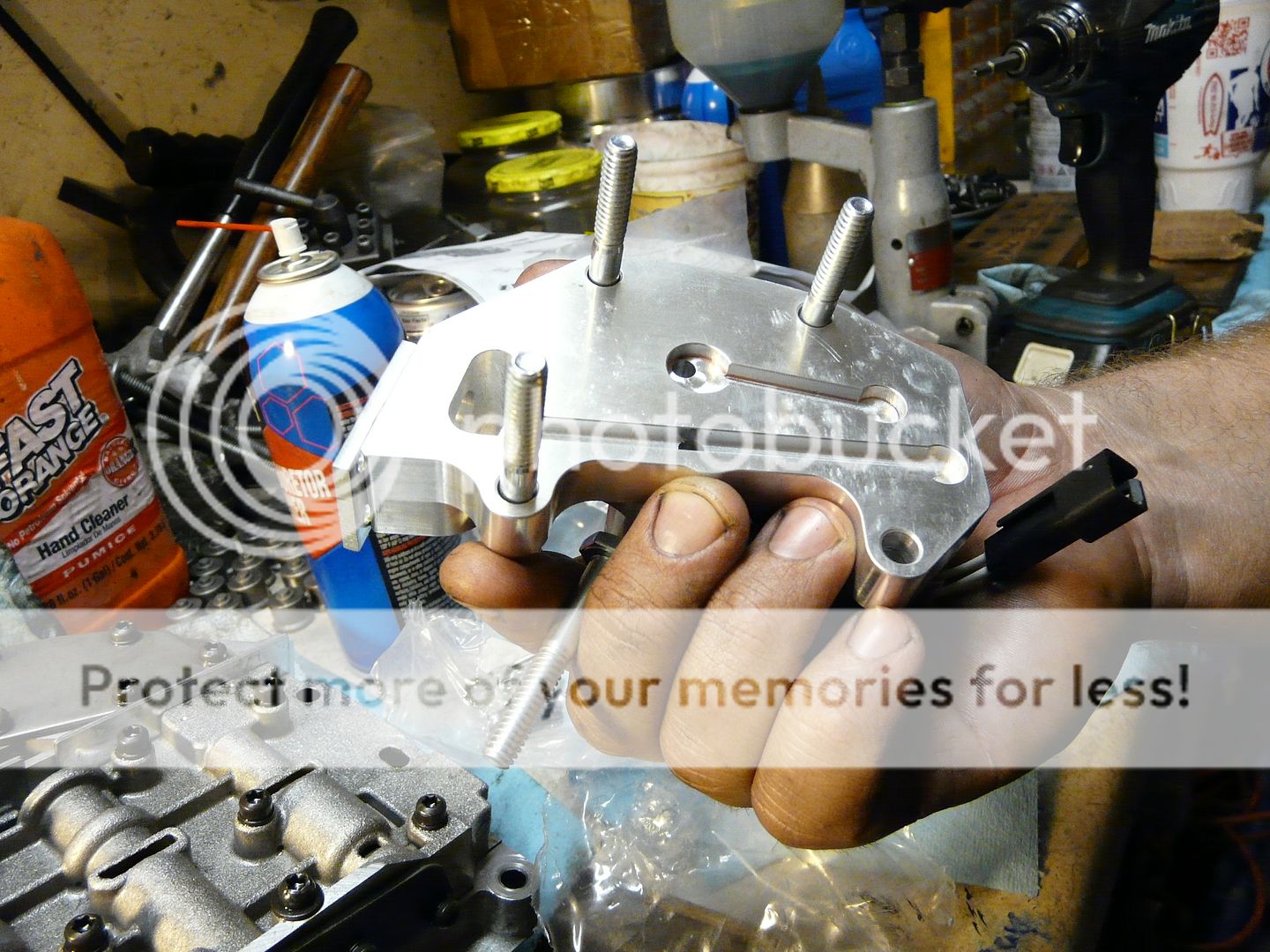

I always replace all electronic components in non-personal rebuilds. I can deal with an electrical failure, but a custom generally won't accept it. All electronics are replaced with new factory style parts except the governor solenoid. For the governor solenoid, many upgrade to the newer $60 Borg solenoid that seems to handle elevated line pressure better than the stock Dodge part. One step further is this custom machined block by DNJ with a Chevy 4L60e transmission solenoid. This upgrade used to cost $300 but with higher production and general usage and competition the cost has come down to $150-$200 range.