blu_by_u

Diesel Head

I actually started this project on June 22nd but have been taking pictures and my sweet time appearantly.

I decided that it would be best for me to pull the engine out of the truck since I wanted to also replace several gaskets and seals during this opportunity. Plus it would also allow me to paint the engine much easier.

Here is where the truck will be sitting for a while now. I'm already draining the coolant in this pic.

The engine as it looks with the VP44.

It's hiding in there, hoping that I can't find it and exterminate it but I know exactly where to find that pesky little VP44

Off comes the bumper.

Next the radiator, charge air cooler, and move the freon condenser off to the side.

Close up of the exposed engine.

The next day arrives with help to actually pull the engine out.

After being "sure" countless times that I disconnected all of the harnesses, wires, cables and hoses, the engine is FINALLY free of the truck!

Here the engine is sitting on the floor. I'm not crazy about it just being a stack of lumber that the engine is sitting, though.

Empty engine bay.

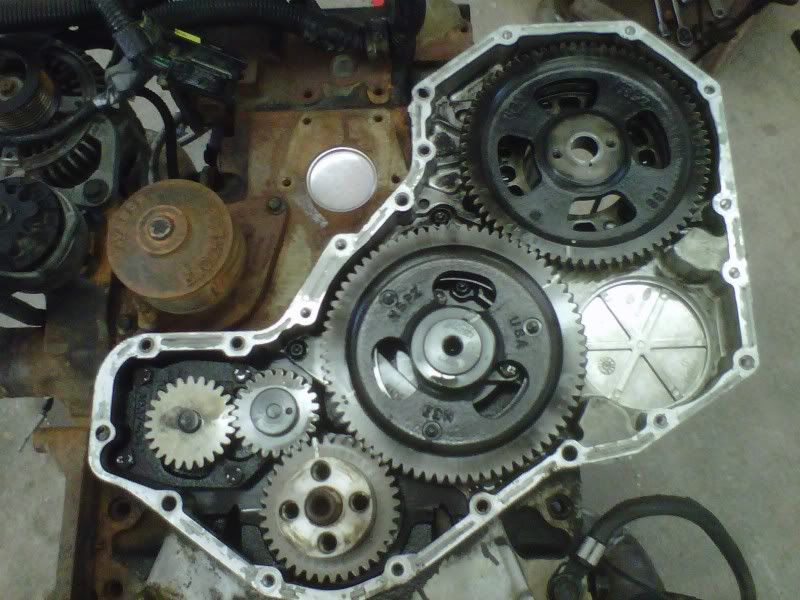

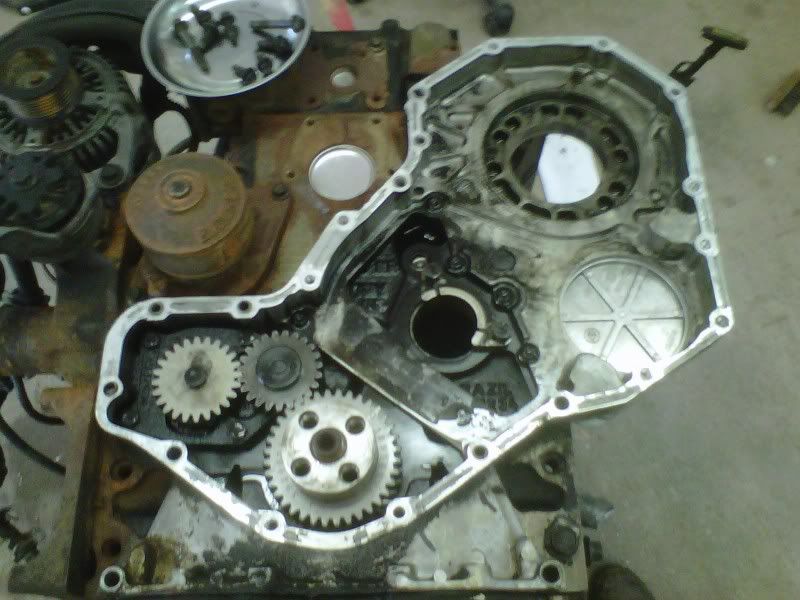

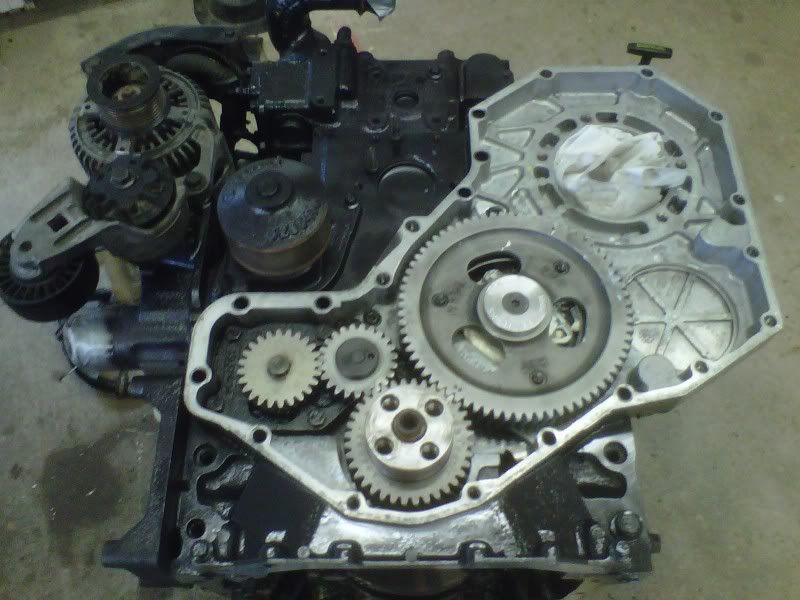

A good friend of mine taught me that these engines sit nicely on the flywheel housing. This is EXTREMELY helpful for a couple of reasons.

The first and obvious reason that this is helpful is to be able to pull the oil pan off easily to inspect the main bearings.

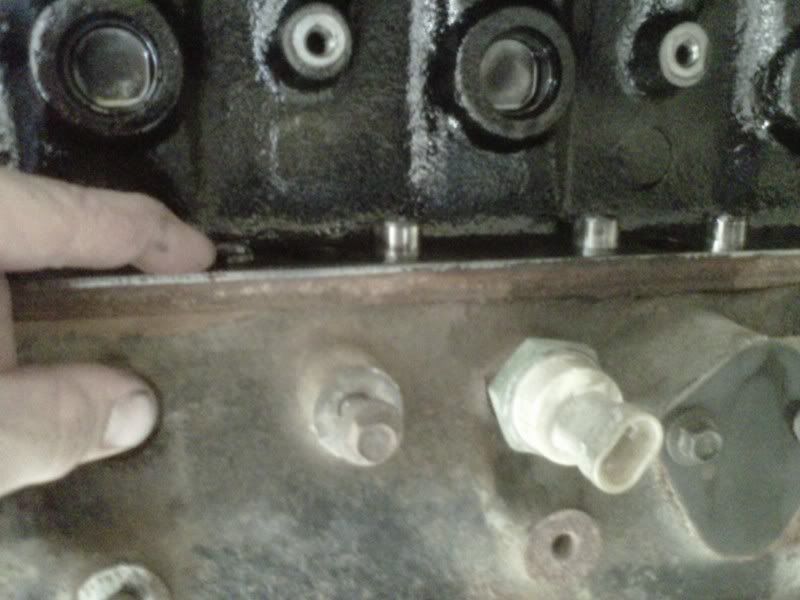

I pulled the #4 mian cap.

I couldn't be more happy with what I see at almost 200,000 miles. So I put the cap back on and didn't even touch the rest of the mains and rod caps. I feel like I would be running into a greater risk of causing damage by changing bearings when I didn't need to.

I decided that it would be best for me to pull the engine out of the truck since I wanted to also replace several gaskets and seals during this opportunity. Plus it would also allow me to paint the engine much easier.

Here is where the truck will be sitting for a while now. I'm already draining the coolant in this pic.

The engine as it looks with the VP44.

It's hiding in there, hoping that I can't find it and exterminate it but I know exactly where to find that pesky little VP44

Off comes the bumper.

Next the radiator, charge air cooler, and move the freon condenser off to the side.

Close up of the exposed engine.

The next day arrives with help to actually pull the engine out.

After being "sure" countless times that I disconnected all of the harnesses, wires, cables and hoses, the engine is FINALLY free of the truck!

Here the engine is sitting on the floor. I'm not crazy about it just being a stack of lumber that the engine is sitting, though.

Empty engine bay.

A good friend of mine taught me that these engines sit nicely on the flywheel housing. This is EXTREMELY helpful for a couple of reasons.

The first and obvious reason that this is helpful is to be able to pull the oil pan off easily to inspect the main bearings.

I pulled the #4 mian cap.

I couldn't be more happy with what I see at almost 200,000 miles. So I put the cap back on and didn't even touch the rest of the mains and rod caps. I feel like I would be running into a greater risk of causing damage by changing bearings when I didn't need to.