Hi folks.

Seeking advice on a newly rebuilt 2006 Sprinter turbodiesel engine that suffered an improper engine break -in. Please bear with me as I throw a lot of info at y'all.

This is the Mercedes 647 engine, 5 cyl. 2.7l common rail with variable gate turbo used in small box trucks and RV's.. not a hot rod.

The newly rebuilt engine had an airlock, so only had 1/2 the coolant in it during the 1st break-in drive. When I saw the temperature guage shoot up after 4 miles of driving, I shut off the engine, but the pistons seized as engine was shutting down. Later upon adding coolant, and completing the break-in, engine ran good, and did not seem to have too much blowby, and had good oil analysis samples. But used way too much oil. Scan tool compression check seemed good. 25,000 miles later, head gasket leak pressurizes radiator, so engine is torn down.

Tops of pistons were carboned up; good cyl. crosshatching; except for what I believe is a little top bore polishing from the carbon. Pistons are good.The problem is some very thin vertical scores from the pistons grabbing. Piston to cyl clearance is about 0.0027". These are almost brand new oversize Mahle pistons/rings, so I want to just flexhone the cylinders for new rings. I know the worst scores will remain. I am HOPING with a proper engine break-in the scores will not cause bad oil consumption. Because the blowby didnt seem too bad earlier. My THEORY is that the oil consumption was mainly caused by the improper ring break-in, not the scores, but I have NO experience in this matter. This is just a WAG.

Some of the TDI volkswagon folks use a 240 grit flexhone with the chromed rings in the cast iron block, for a re-ring job and new connecting rod bearings/bolts and head fix. That is my plan. Because it will save a lot of money. What do you folks think? Are these scores so bad a flexhone and rings won't solve the oil consumption problem?

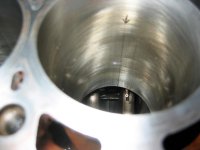

Shown are 2 photos per piston. Only the scores that will catch a fingernail are denoted with arrows. Photo 1b of Cyl#1 has the deepest score. Thanks for your comments and experiences with this kind of re-ring job.

Seeking advice on a newly rebuilt 2006 Sprinter turbodiesel engine that suffered an improper engine break -in. Please bear with me as I throw a lot of info at y'all.

This is the Mercedes 647 engine, 5 cyl. 2.7l common rail with variable gate turbo used in small box trucks and RV's.. not a hot rod.

The newly rebuilt engine had an airlock, so only had 1/2 the coolant in it during the 1st break-in drive. When I saw the temperature guage shoot up after 4 miles of driving, I shut off the engine, but the pistons seized as engine was shutting down. Later upon adding coolant, and completing the break-in, engine ran good, and did not seem to have too much blowby, and had good oil analysis samples. But used way too much oil. Scan tool compression check seemed good. 25,000 miles later, head gasket leak pressurizes radiator, so engine is torn down.

Tops of pistons were carboned up; good cyl. crosshatching; except for what I believe is a little top bore polishing from the carbon. Pistons are good.The problem is some very thin vertical scores from the pistons grabbing. Piston to cyl clearance is about 0.0027". These are almost brand new oversize Mahle pistons/rings, so I want to just flexhone the cylinders for new rings. I know the worst scores will remain. I am HOPING with a proper engine break-in the scores will not cause bad oil consumption. Because the blowby didnt seem too bad earlier. My THEORY is that the oil consumption was mainly caused by the improper ring break-in, not the scores, but I have NO experience in this matter. This is just a WAG.

Some of the TDI volkswagon folks use a 240 grit flexhone with the chromed rings in the cast iron block, for a re-ring job and new connecting rod bearings/bolts and head fix. That is my plan. Because it will save a lot of money. What do you folks think? Are these scores so bad a flexhone and rings won't solve the oil consumption problem?

Shown are 2 photos per piston. Only the scores that will catch a fingernail are denoted with arrows. Photo 1b of Cyl#1 has the deepest score. Thanks for your comments and experiences with this kind of re-ring job.