You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Transmission gurus!

- Thread starter blackmega3500

- Start date

blackmega3500

New member

Oh ? Then what's the post all about again ?

This transmission takes more abuse moving this heavy truck around every day, and most other units couldn't handle it.

Simply put, the 48 isn't for my liking or driving habits and I enjoy my double OD!

biggy238

Active member

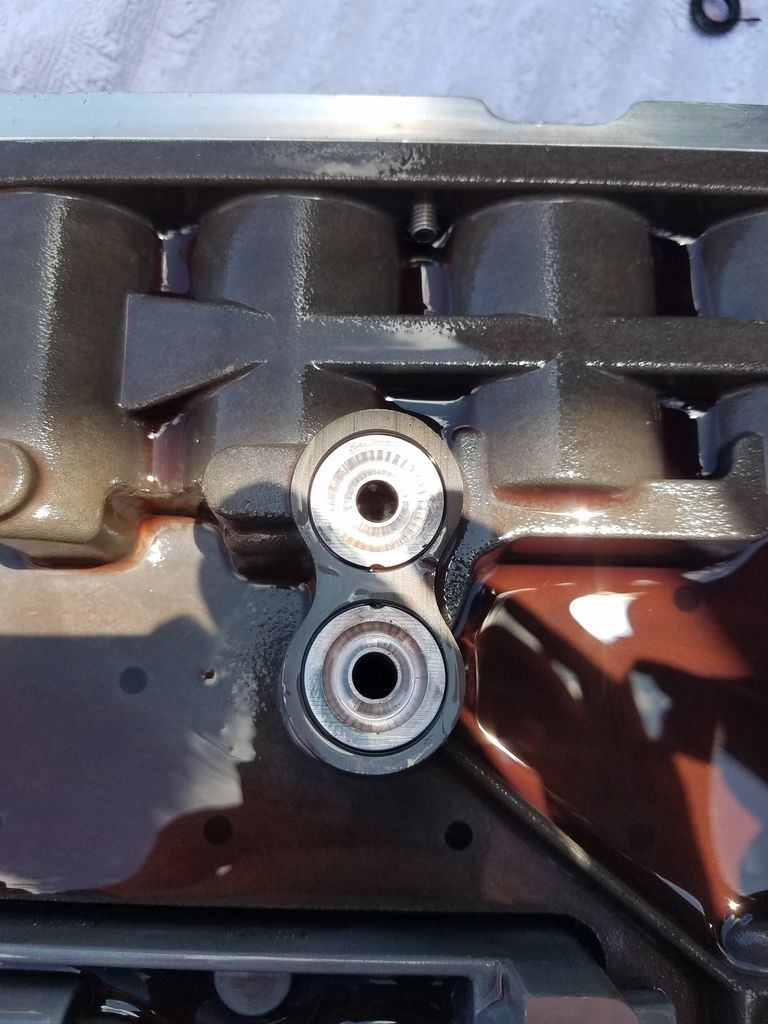

That oring face seal(s) should handle easy more pressure. Something is reducing clamp load or the oring cross section is undersizedYou can see here the cut outs for the O-ring, in addition to the added carnage from when I bolted up the valve body on last evaluation.

I also inspected for any new signs of any metal or spring and nothing was found.

I went ahead and performed the air check and no massive air leaks were noticed and 2C and 4C both held 30psi and you can hear 4 engage with pressure.

https://www.youtube.com/watch?v=J3HzXr9rkrg

Went ahead and replaced seals on billet pieces(have oem ones ready for a backup), torqued unit all around to 110in lbs and refilled.

Noticeably better and now its acting normal. Now I plan on seeing what the CVIs are soon, and then allowing the trans to do an adaptive relearn.

Sent from my XT1575 using Tapatalk

blackmega3500

New member

That oring face seal(s) should handle easy more pressure. Something is reducing clamp load or the oring cross section is undersized

Sent from my XT1575 using Tapatalk

The broken o-ring had lost enough surface material to allow washout on the 4C. This led to practically no low rpm line pressure, and enough bleed to allow the whole valve body to loose psi across the deck.

The tricky part was this issue mixed with the 68s adaptive TCM. It basically was constantly trying to fixed the 3-4 shift and since it was never seeing the needed line psi it was always "learning". Now the seals fixed, all shifts are back up and banging away like usual.

I've put on about 500ish miles since and the TCM CVIs have all learned what they should be now and no longer have any "delay" or slip.