You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3 point hung up

- Thread starter 973604x4

- Start date

sootman

Banned

When your truck is ready to pick up bring that tractor and I'll fix it. Probably a John Deere dealer closer ready to take your wallet though.:hehe:973604x4 said:got an 02 5205 4x4. the 3 point is stuck all the way up. When i move the lever controlling the 3point, nothing happens. No hydraulic noises or anything. Help?!

Signature600

THA MAN!

Usually when I'm trouble shooting a hydraulic system, first I ask them to check the linkage, make sure it's moving! Could also be a spool valve sticking. Not sure how the 5205 Deere system is configured, but our cheaper tractors in that size range are mostly internal parts, with only some linkage on the outside!

A Deere dealer would be the best bet though!

Chris

A Deere dealer would be the best bet though!

Chris

973604x4

aka landphil

Burner said:I wonder if it'll go down with the engine off?

nope tried that too.

this damn thing has been problematic since day 1. It likes to eat through fuel lines really fast for some reason.

Signature600

THA MAN!

Maybe there is a Burrito stuck in the lift cylinder??

Chris

Chris

sootman

Banned

What do you mean about the fuel lines? Do you mean at the injectors? Those stupid little orings on the injectors and crossover tubes are junk. You know what they say" Nothing runs from work like a Deere!" :hehe: LOL973604x4 said:nope tried that too.

this damn thing has been problematic since day 1. It likes to eat through fuel lines really fast for some reason.

OneBigDoofus

New member

One thing a feller might look at iis the "Rate of Drop" Valve.

You might have already checked this but I thought I'ed mention it.

Got any yound kid's around? The valve is just about the right height for a 4 year old. LOL

If kids are not the problem then maybe trash in the system has pluged the orifice. Try cranking the "rate of drop valve" all the way in & all the way out a few times to see if it clears it's self:bang

You might have already checked this but I thought I'ed mention it.

Got any yound kid's around? The valve is just about the right height for a 4 year old. LOL

If kids are not the problem then maybe trash in the system has pluged the orifice. Try cranking the "rate of drop valve" all the way in & all the way out a few times to see if it clears it's self:bang

Its an easy fix.. but it could happen again.. Its all the moisture we have been getting.. is causing a very small about of rust on the valve.. causing it to stick.. I've fixed a bunch.. There is also an updated Stainless Steel valve that has been the cure.. but you can pull out the valve.. and clean it.. and it will work....

I'll try posting the instructions..

Bryan

I'll try posting the instructions..

Bryan

**Paper copies of solutions may not be the most current solutions**

Complaint or Symptom :

Rockshaft is stuck in the raised position.

Problem or Situation :

The Rockshaft Control Valve has stuck as the result of corrosion on the spool inside the valve.

Solution :

To prevent the Rockshaft Control Valve from sticking, apply TY25744 grease into the Discharge Valve per the following procedures.

Tools needed:

1 - 5mm Allen key

1 - 17mm Wrench

1 - 13mm Wrench

1 - Flat Tip Screw Driver

1. Remove the seat assembly. (On the 03's its two 18mm, and you will have to slide the seat to find the hole in the seat frame to access the bolt, I have not had to do an 05.. its same valve on both tractors.)

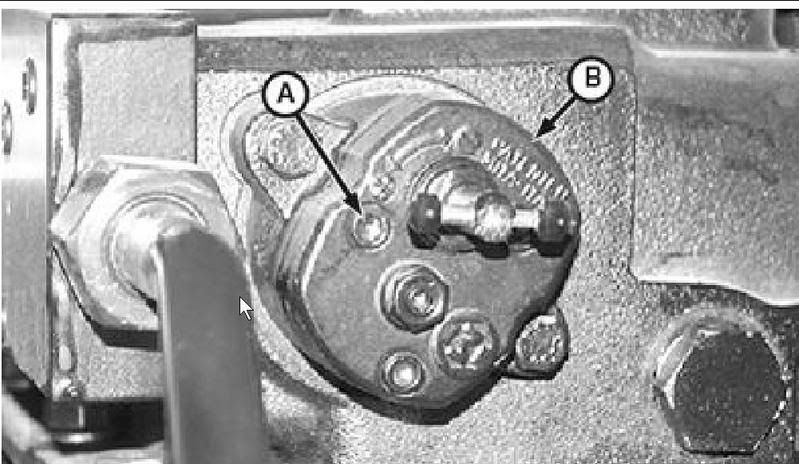

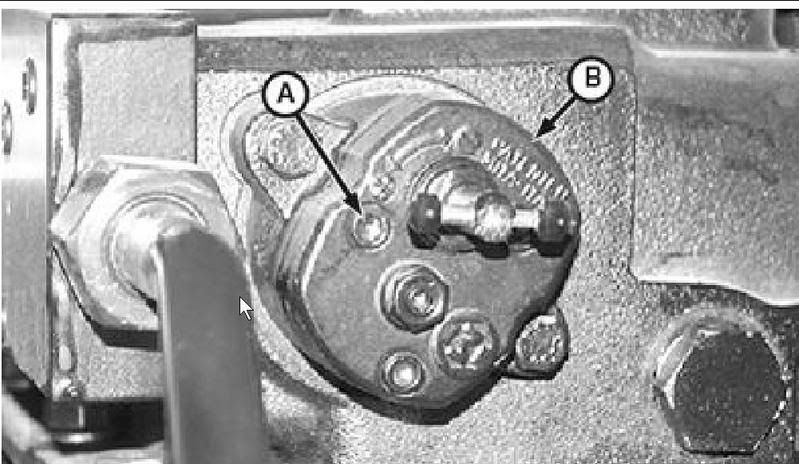

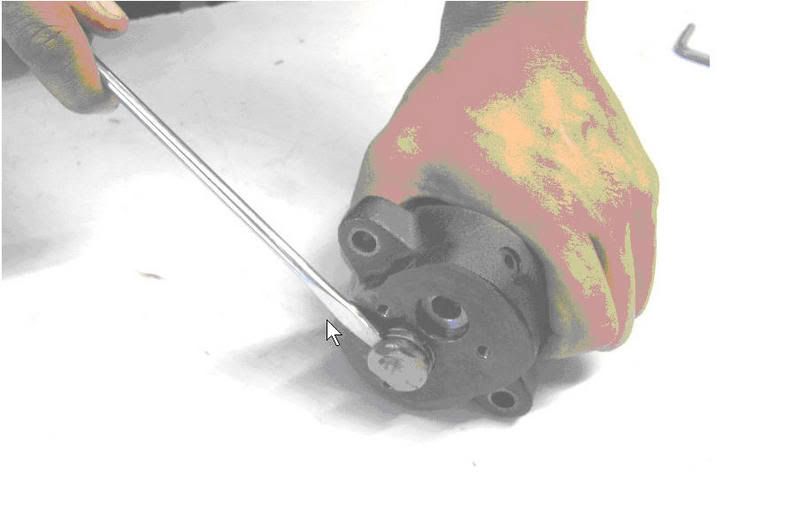

2. Remove the three (3) M6 Allen head screws. Firmly grab tee handle and pull straight out, removing rate-of-drop valve assembly from Rockshaft Control Valve.

(They should be 5mm.)

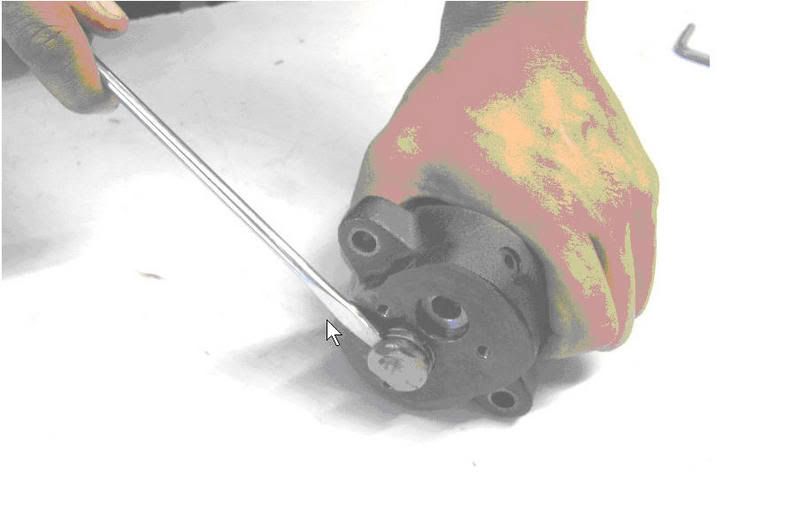

3. Remove the Discharge valve from the Control Valve body. Use of a screwdriver may be required. (The picture below shows the valve housing removed from the tractor.. I have not had to remove one.. yet..)

4. Once the Discharge valve is removed from the Control Valve body, inspect the condition of the O-rings and washers. Ensure free movement of the Poppet valve in the spool body.

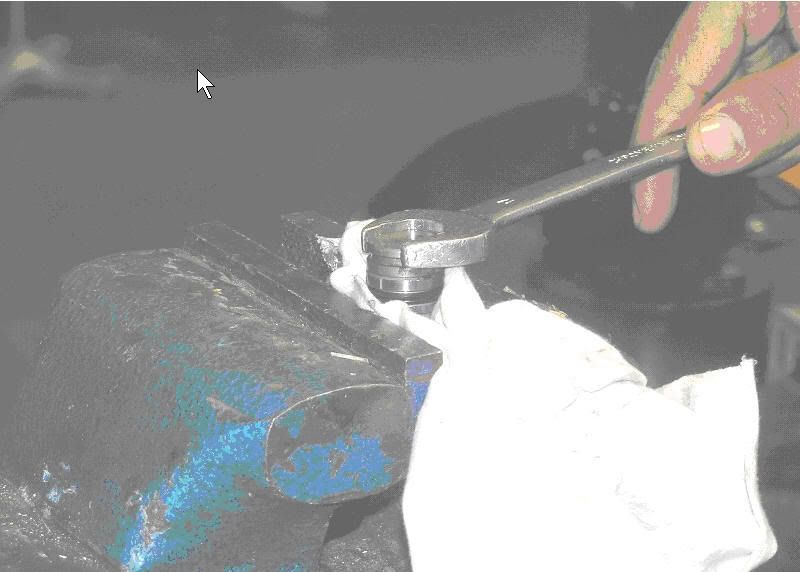

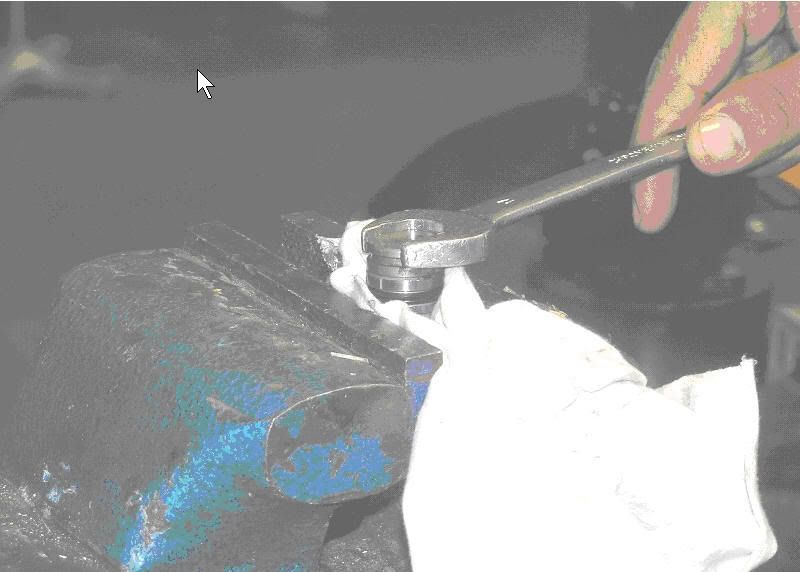

5. Using a 17mm wrench, remove the Discharge Cap from the Control Valve body. (Once you take the cap off, the spring will come out. The spool will probably be stuck. You will have to push it out from the other end. If you look in the spool housing you will probably see a very small about of rust. It takes very little for it to stick.)

6. If Discharge Valve Poppet is rusty, then clean with a fine emery cloth. Clean the parts. Apply TY25744 grease into the Discharge Valve and, reassemble.

7. Install the Discharge valve into the Control Valve. Follow reverse procedure for assembly of the Control Valve.

Some of the instructions have you removing the valve housing from the tractor. (the two 13mm headed bolts.) but I have never had to remove one... yet..)

I cut and pasted some pics from various places... some from the manuals.. some from some JD solutions... (All of the pics are John Deere Reference materials, the instructions are my modified version.. )

This should get you going.. let me know if you have any problems...

Bryan

Complaint or Symptom :

Rockshaft is stuck in the raised position.

Problem or Situation :

The Rockshaft Control Valve has stuck as the result of corrosion on the spool inside the valve.

Solution :

To prevent the Rockshaft Control Valve from sticking, apply TY25744 grease into the Discharge Valve per the following procedures.

Tools needed:

1 - 5mm Allen key

1 - 17mm Wrench

1 - 13mm Wrench

1 - Flat Tip Screw Driver

1. Remove the seat assembly. (On the 03's its two 18mm, and you will have to slide the seat to find the hole in the seat frame to access the bolt, I have not had to do an 05.. its same valve on both tractors.)

2. Remove the three (3) M6 Allen head screws. Firmly grab tee handle and pull straight out, removing rate-of-drop valve assembly from Rockshaft Control Valve.

(They should be 5mm.)

3. Remove the Discharge valve from the Control Valve body. Use of a screwdriver may be required. (The picture below shows the valve housing removed from the tractor.. I have not had to remove one.. yet..)

4. Once the Discharge valve is removed from the Control Valve body, inspect the condition of the O-rings and washers. Ensure free movement of the Poppet valve in the spool body.

5. Using a 17mm wrench, remove the Discharge Cap from the Control Valve body. (Once you take the cap off, the spring will come out. The spool will probably be stuck. You will have to push it out from the other end. If you look in the spool housing you will probably see a very small about of rust. It takes very little for it to stick.)

6. If Discharge Valve Poppet is rusty, then clean with a fine emery cloth. Clean the parts. Apply TY25744 grease into the Discharge Valve and, reassemble.

7. Install the Discharge valve into the Control Valve. Follow reverse procedure for assembly of the Control Valve.

Some of the instructions have you removing the valve housing from the tractor. (the two 13mm headed bolts.) but I have never had to remove one... yet..)

I cut and pasted some pics from various places... some from the manuals.. some from some JD solutions... (All of the pics are John Deere Reference materials, the instructions are my modified version.. )

This should get you going.. let me know if you have any problems...

Bryan

Last edited:

KTA-Cummins

Diesel Doctor

Buy some silicone fuel line and put on it and never have that problem again. The mexicans deere sourced the fuel line to for the 5003/5005 series tractors make their rubber out of something that self destructs when exposed to air. We have had a bunch of them dry rot crack and go to sucking air, the rubber is cheap and it sucks, buy the silicone and forget it!

973604x4

aka landphil

KTA-Cummins said:Buy some silicone fuel line and put on it and never have that problem again. The mexicans deere sourced the fuel line to for the 5003/5005 series tractors make their rubber out of something that self destructs when exposed to air. We have had a bunch of them dry rot crack and go to sucking air, the rubber is cheap and it sucks, buy the silicone and forget it!

yea thats what keeps happening. dry rot and cracking.

JDGnut- WOW. awesome instructions. I know you emailed me about it but I just hadn't come to look til i got ready to go out to the ranch. holy damn. Thanks alot bud.

i may go out there this weekend and give it a shot....i need to get my truck first though....

shade tree

New member

Just a note of thanks for the repair instructions!

We had finally got some rain and I needed to bush hog, when lo and behold I find the rocker arm is stuck. I searched several other sites, more tractor related than yours and got nowhere. I had already removed the valve housing but was unsure of how to proceed. I was just about ready to load it up and take it to my mechanic when I yahooed instead of googled and found your site.

The photos were what I needed. The only thing I found upon disassembly was some rust on the rate of descent valve and the spool was stuck. I buffed well with emery cloth, greased well, and reassembled. Now I am fully operational.

I and my pocket book thank you.

Robert

We had finally got some rain and I needed to bush hog, when lo and behold I find the rocker arm is stuck. I searched several other sites, more tractor related than yours and got nowhere. I had already removed the valve housing but was unsure of how to proceed. I was just about ready to load it up and take it to my mechanic when I yahooed instead of googled and found your site.

The photos were what I needed. The only thing I found upon disassembly was some rust on the rate of descent valve and the spool was stuck. I buffed well with emery cloth, greased well, and reassembled. Now I am fully operational.

I and my pocket book thank you.

Robert