COMP461

Comp Diesel Sponsor

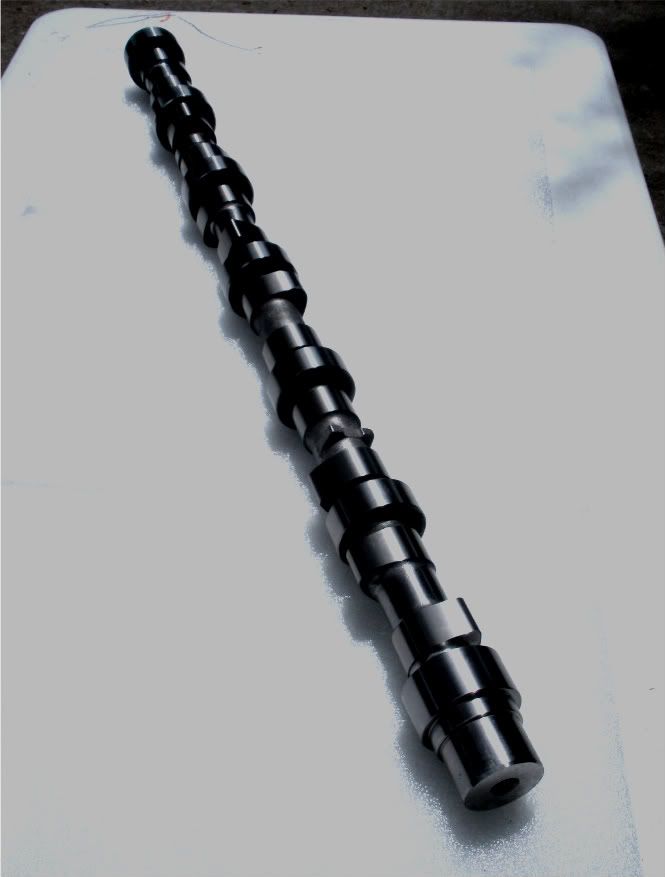

A few months ago, I finally pulled the trigger on releasing the next member of the MaxSpool Magnum series. The Magnum series is my most power Pro Street cam today. This is a no holds barred street cam, require piston to valve clearance modification, and MaxSpool Dual Springs. I have always wanted to do this cam, and the computer modeling screamed “Grind this cam, and it will make power”.

The new 207 Magnum Cam in the most advanced street cam available. The advanced symmetric lobe design , controls the valve train movements like no cam in diesel history.

This advance design allows more area under the curve, meaning more air in the motor, and dropping boost number 25% allowing a cooler intake charge.

This cam work well with high flowing cylinder heads, like the ones Greg at ZZ custom fabrication is currently turning out, but also picks up dramatic gains in stock heads.

The specs are 207-intake 216 exhaust 112 to 118 lobe separation angle depending on application. I grind each cam for the individual, no foreran cookie cutter cams here

The first cams are in motors and the results are dramatic.

The new 207 Magnum Cam in the most advanced street cam available. The advanced symmetric lobe design , controls the valve train movements like no cam in diesel history.

This advance design allows more area under the curve, meaning more air in the motor, and dropping boost number 25% allowing a cooler intake charge.

This cam work well with high flowing cylinder heads, like the ones Greg at ZZ custom fabrication is currently turning out, but also picks up dramatic gains in stock heads.

The specs are 207-intake 216 exhaust 112 to 118 lobe separation angle depending on application. I grind each cam for the individual, no foreran cookie cutter cams here

The first cams are in motors and the results are dramatic.