Last week testing for FIA Truck Race where as for this year we have to run a HVO diesel.

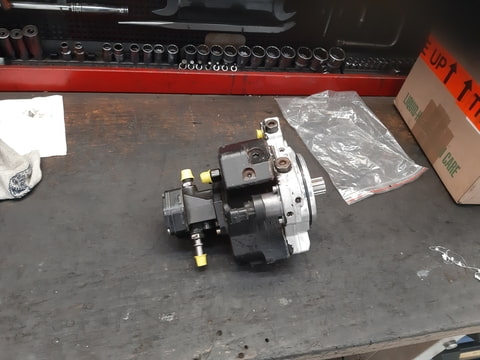

Not going into detail about this bio diesel but think we get a great performance level out of it with changing engine settings and still improvement possible with a fuel and turbo system upgrades on the D26E6B engine turning it into an A or even A+ spec engine.

Last day spend on the track focus was on getting the correct engine power setting for the track conditions brining the lap time down a lot more than expected mainly keeping traction getting faster corner exit time as a result.

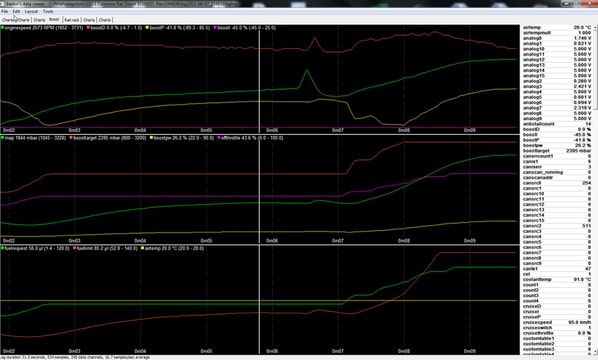

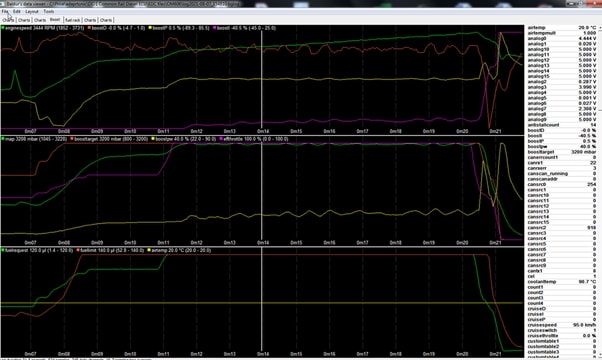

For those who think you can not run Lambda one all the time I have news we run these race engine from 13.8AFR low RPM max toque till hi end between 14,5 and 15 AFR. It’s all about correct combustion chamber fuel system fuel pressure and timing. Why so lean? Well like the rest we have to run a 63mm inlet restrictor in front of the turbo compressor restricting air mass and power and we can not smoke so it’s all about the details getting to that point. You can call it good or bad but if it smokes it’s losing power so that’s making a fuel mass set-up les complicated still have to go over a ton of ECU and data log data to find improvement on performance.

Bases on fuel we now make 5300Nm and 808Kw x 1.36 for hp makes 1099hp and even op top end @ 2452Rpm we make 801Kw so this 63mm inlet restrictor in front of the turbo compressor dos do it’s work well.

[ame="http://www.youtube.com/watch?v=Z9FIeqkBVZk"]Fia Truck Race Testing Most part 1 - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=iKhyCdrsoXE"]Fia Truck Race Testing Most part 2 - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=cxZ8pSXl_oM"]Fia Truck Race Testing Most part 3 - YouTube[/ame]

Not going into detail about this bio diesel but think we get a great performance level out of it with changing engine settings and still improvement possible with a fuel and turbo system upgrades on the D26E6B engine turning it into an A or even A+ spec engine.

Last day spend on the track focus was on getting the correct engine power setting for the track conditions brining the lap time down a lot more than expected mainly keeping traction getting faster corner exit time as a result.

For those who think you can not run Lambda one all the time I have news we run these race engine from 13.8AFR low RPM max toque till hi end between 14,5 and 15 AFR. It’s all about correct combustion chamber fuel system fuel pressure and timing. Why so lean? Well like the rest we have to run a 63mm inlet restrictor in front of the turbo compressor restricting air mass and power and we can not smoke so it’s all about the details getting to that point. You can call it good or bad but if it smokes it’s losing power so that’s making a fuel mass set-up les complicated still have to go over a ton of ECU and data log data to find improvement on performance.

Bases on fuel we now make 5300Nm and 808Kw x 1.36 for hp makes 1099hp and even op top end @ 2452Rpm we make 801Kw so this 63mm inlet restrictor in front of the turbo compressor dos do it’s work well.

[ame="http://www.youtube.com/watch?v=Z9FIeqkBVZk"]Fia Truck Race Testing Most part 1 - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=iKhyCdrsoXE"]Fia Truck Race Testing Most part 2 - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=cxZ8pSXl_oM"]Fia Truck Race Testing Most part 3 - YouTube[/ame]