CSM diesel

Engineer

- Joined

- Jun 1, 2007

- Messages

- 479

This is more of an update thread so to speak...

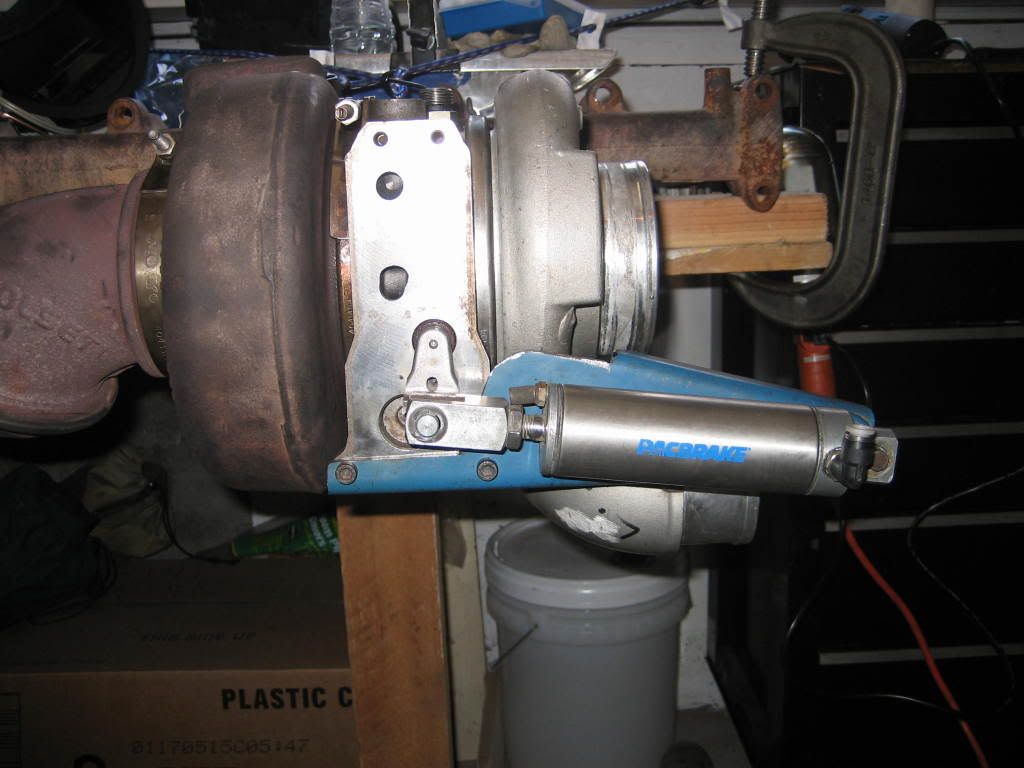

I have found the flanges to build an adapter for the odd ball he351ve flange to adapt it to a standard T3 flange.

I will use a single acting spring closure air cyl. from an exhaust brake.

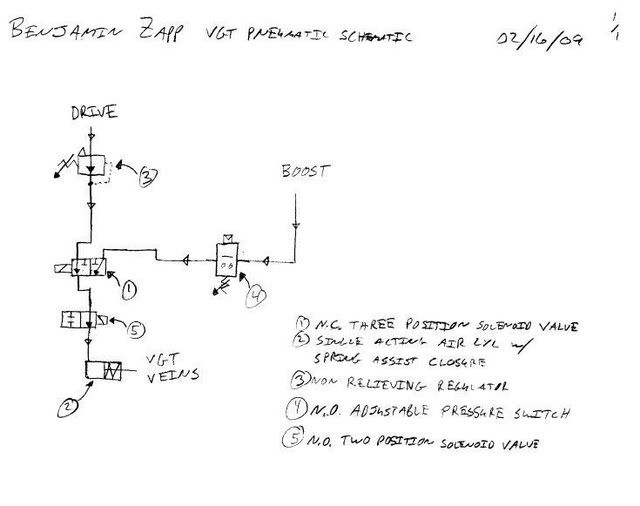

Here is a pneumatic schematic for the VGT actuation:

The thought process is that the neutral position of the cyl (fully closed by the spring) will hold the veins in their closed position, or slid all the way in (exhaust brake mode.)

This causes concern as the default for the system is fully closed (i.e. exhaust brake mode.) To overcome this a non-relieving adjustable pressure regulator will be in line from the drive pressure port. Drive pressure will hold the air cyl open slightly to the minimum vein position TBD.

From there, as the turbo spools and boost increases, A pressure actuated electric switch (hobbs switch) will close at a TBD boost pressure and activate the three way valve.

This will switch the supply pressure to the air cyl from being the regulated drive pressure to boost pressure.

The vein position will now slide out and open up the volute area as boost pressure increases.

To activate the exhaust brake mode, a two way solenoid valve will be closed allowing the spring in the cyl to close the veins all the way down.

Thoughts? Suggestions? Am I crazy for doing this?

:st:

I have found the flanges to build an adapter for the odd ball he351ve flange to adapt it to a standard T3 flange.

I will use a single acting spring closure air cyl. from an exhaust brake.

Here is a pneumatic schematic for the VGT actuation:

The thought process is that the neutral position of the cyl (fully closed by the spring) will hold the veins in their closed position, or slid all the way in (exhaust brake mode.)

This causes concern as the default for the system is fully closed (i.e. exhaust brake mode.) To overcome this a non-relieving adjustable pressure regulator will be in line from the drive pressure port. Drive pressure will hold the air cyl open slightly to the minimum vein position TBD.

From there, as the turbo spools and boost increases, A pressure actuated electric switch (hobbs switch) will close at a TBD boost pressure and activate the three way valve.

This will switch the supply pressure to the air cyl from being the regulated drive pressure to boost pressure.

The vein position will now slide out and open up the volute area as boost pressure increases.

To activate the exhaust brake mode, a two way solenoid valve will be closed allowing the spring in the cyl to close the veins all the way down.

Thoughts? Suggestions? Am I crazy for doing this?

:st: