I finally bought some injectors for my rig after only running a 14.8 in the 1/4 mile. The stock ones just aren't cutting it. I found a good price on some used 5x.012 injectors so I snatched em up. Should be here on Friday. I figured while I'm waiting on the injectors I should do some upgrading to the stock 131 delivery valves to compliment them...

So I didn't have a delivery valve socket and I am too impatient to wait.

So I drew up and lasers out my own wrench out of some 1/4" stainless.

For anyone who cares; the spline count on the delivery valves IS NOT 32 splines, it is actually 34 splines. Drove myself crazy trying to figure out where I went wrong on the first attempt.

Attempt 2 matched up to the delivery valve perfectly.

Used a 3 jaw drill chuck to hold the valve by the top tit that the spring sits over then chucked that up in the lathe. Since there isn't much meat to hold on to and I'm sure tool pressure would push it out easily, I decided to use a center to keep her nice and true and held in place. Luckily, the valve already has a little center indent on the end.

To my surprise, the material didn't seem too hard; my carbide insert cut right through it like butter.

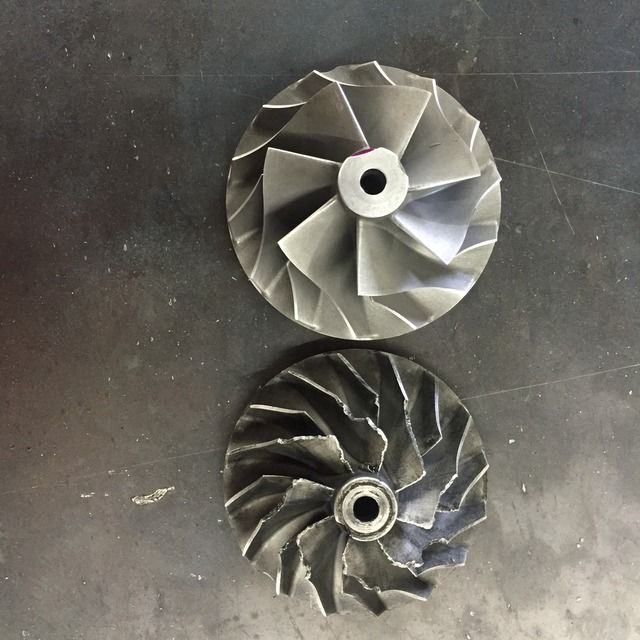

I decided to take .040" off the collar. This is about half of the normal thickness and appears to be close to the 024 valves judging by the pictures. I was able to keep consistently within 0.001 across all 6.

You can see the 2 already turned on each side and the original in the middle.

Overall, I was super happy when I started up the truck and it idles just as smooth as it was before. No hazing at idle. Throttle response is a lot quicker and the turbo seems to light a good 100rpm lower. I can hit 75psi now EASY with the compounds compared to my previous 65psi and the 37s squeal for a good half second when shifting into 2nd gear when before there was nothing.

I would definitely say I am happy with the improvement and cant wait for my injectors! Wish I had time to go to the track to see how much time I shaved off just by doing this mod. Going to be after I install the injectors though.