9724VF350

Tractor Guy

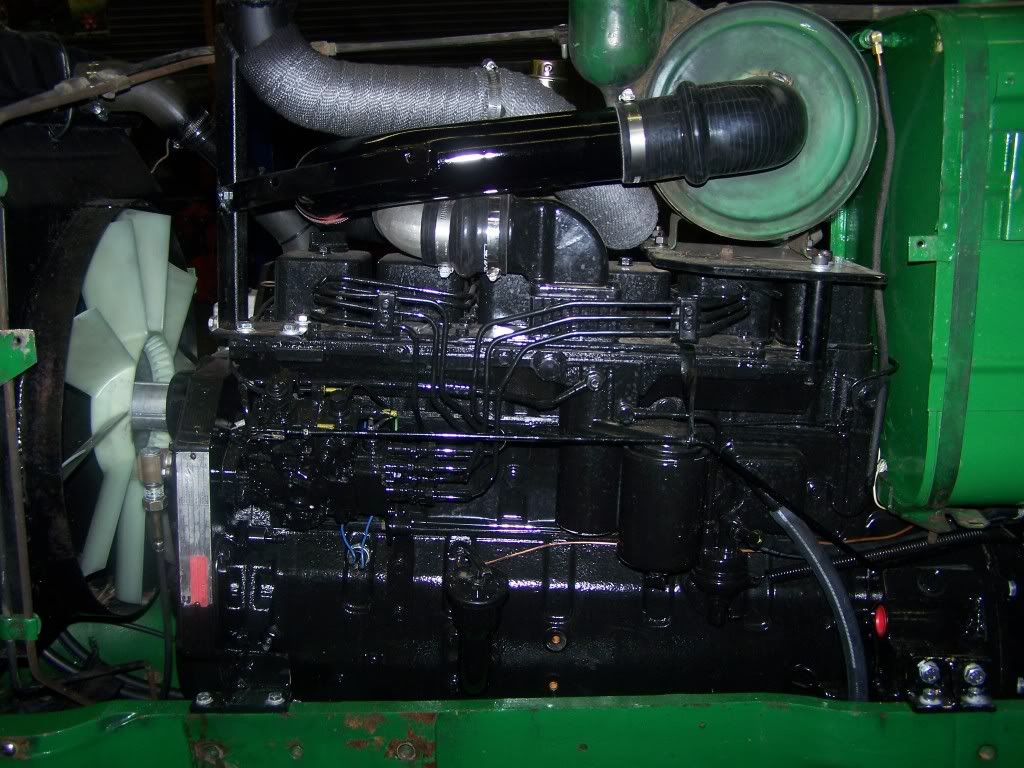

I rebuilt this tractor from end to end about 10 years ago. At that time, if a part was available brand new, it got put in. If not, rebuilt or perfect used parts were used. It was as close to a new tractor as possible.

Recently the customer had another tractor that had the engine go down, so they decided to repower this one and use the engine to keep the other tractor running.

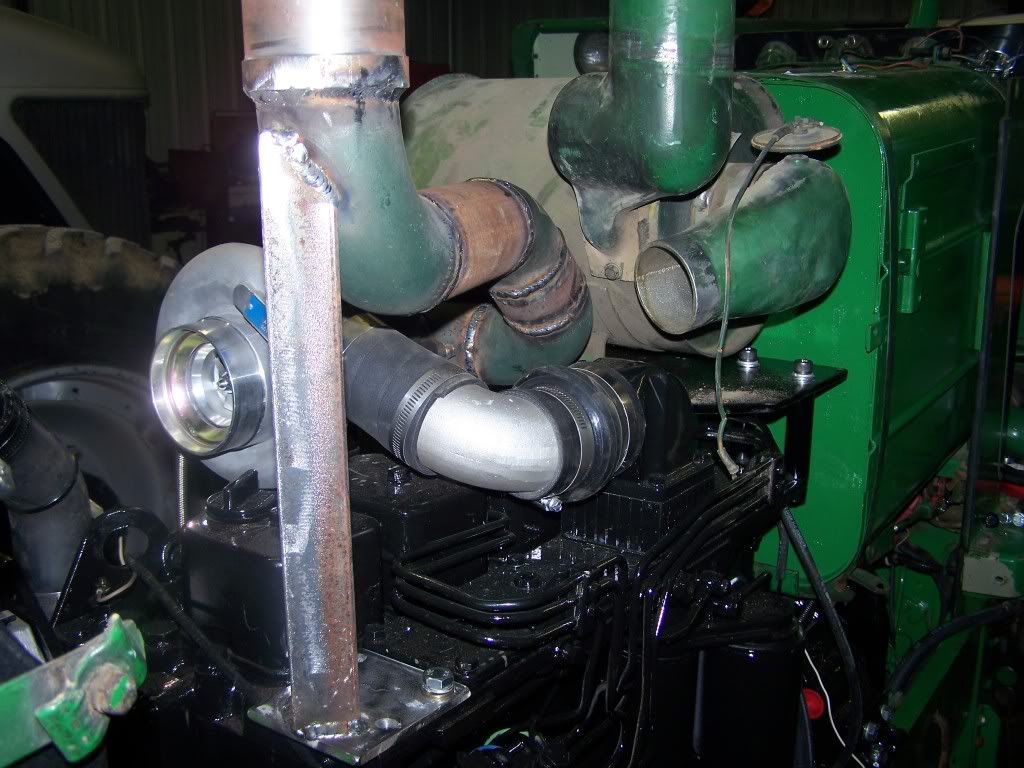

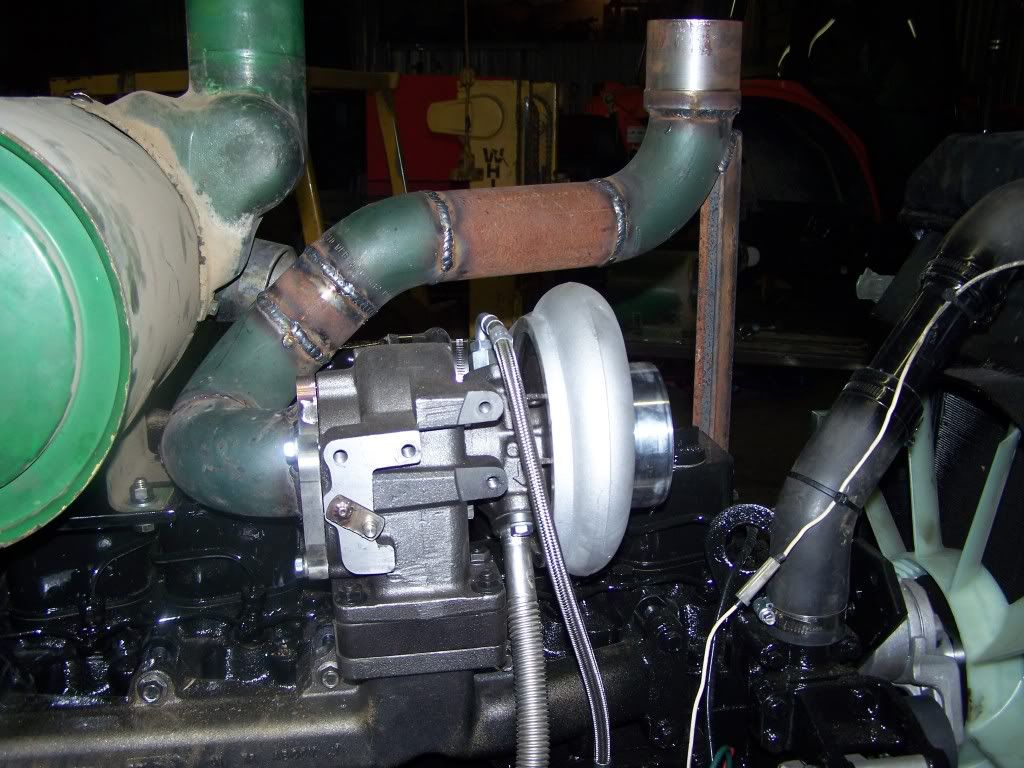

Being front wheel assist caused some oil pan fitment issues that I've never has to deal with on other repowers. I ended up cutting the pan off about 4 inches below the block and started over. I added depth to the front section of the pan to get some oil capacity back. It ended up holding 4 gallon of oil.

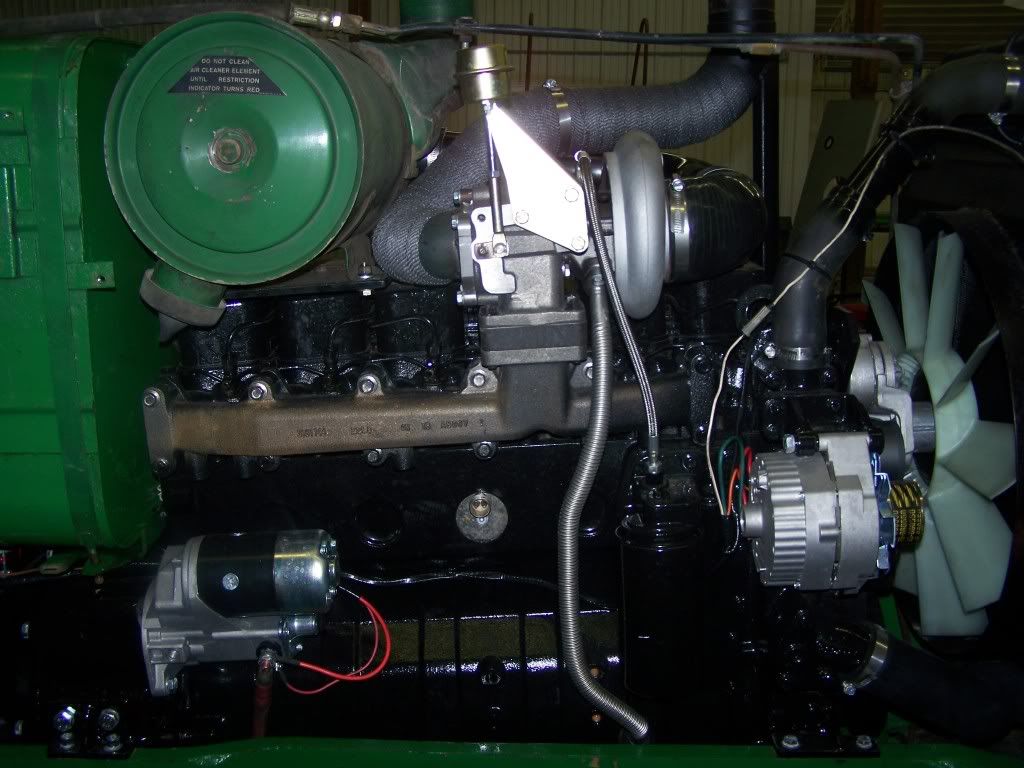

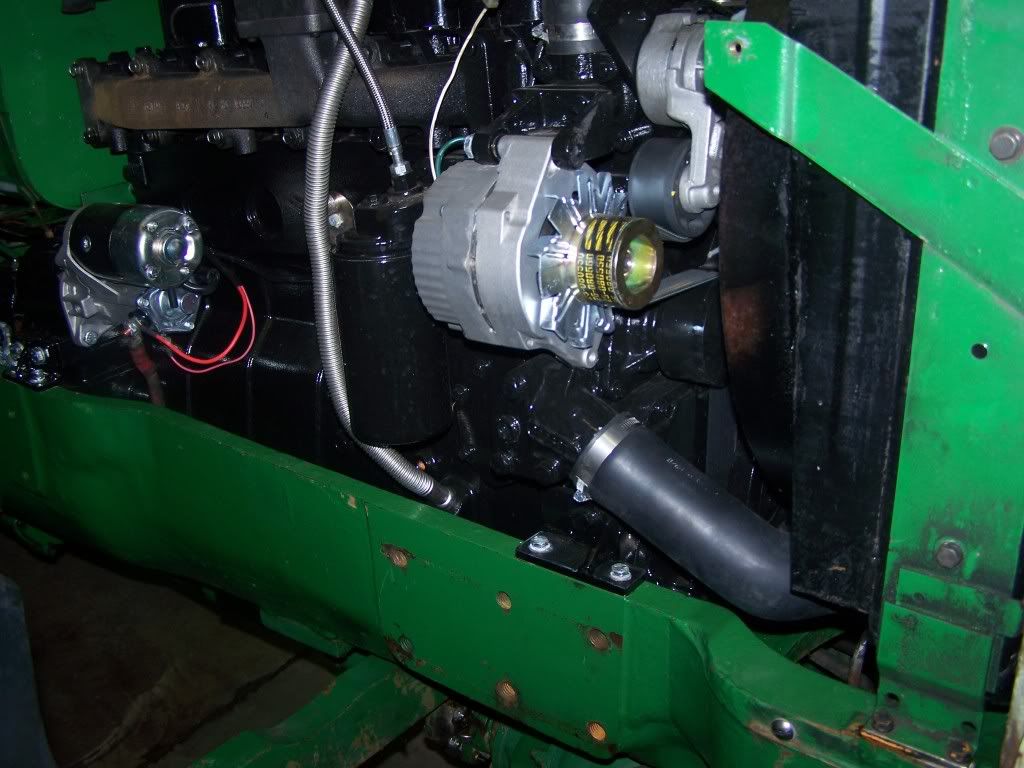

Using the original frame on this model means you have to remove the original motor mounts. this pic is from another repower and you can see where the bottom opening in the frame needs opened up for a 5.9 oil pan. The rear axle support on this one bolts into the 4 holes about in the middle of the frame.

Front and rear motor mounts.

Recently the customer had another tractor that had the engine go down, so they decided to repower this one and use the engine to keep the other tractor running.

Being front wheel assist caused some oil pan fitment issues that I've never has to deal with on other repowers. I ended up cutting the pan off about 4 inches below the block and started over. I added depth to the front section of the pan to get some oil capacity back. It ended up holding 4 gallon of oil.

Using the original frame on this model means you have to remove the original motor mounts. this pic is from another repower and you can see where the bottom opening in the frame needs opened up for a 5.9 oil pan. The rear axle support on this one bolts into the 4 holes about in the middle of the frame.

Front and rear motor mounts.