BC847

New member

Somebody asked a while back that I post something on my heap as of late. It's fixing to snow outside, I'm bored, so . . .. bear with me. It's not as hot as many here, but it's what I have, it's paid for, and I built it myself.

I bought my '93 W250 CC new in late November of '93.

Took to playing at the local 8th mile T&T some years ago now. I've been building up the 12mm VE fueled engine slowly. Was running an S362 over an HT3B up until recently when the bearings of the 3B got too loose. I'd upsized the injectors a year or so before and sorely needed more air then.

Anyhoo, the 3B failing had me get on with moving more air.

The 3B is supposedly good for right at 80lbs/min. I figured around 150lbs/min out to cool the fuel I'm currently moving.

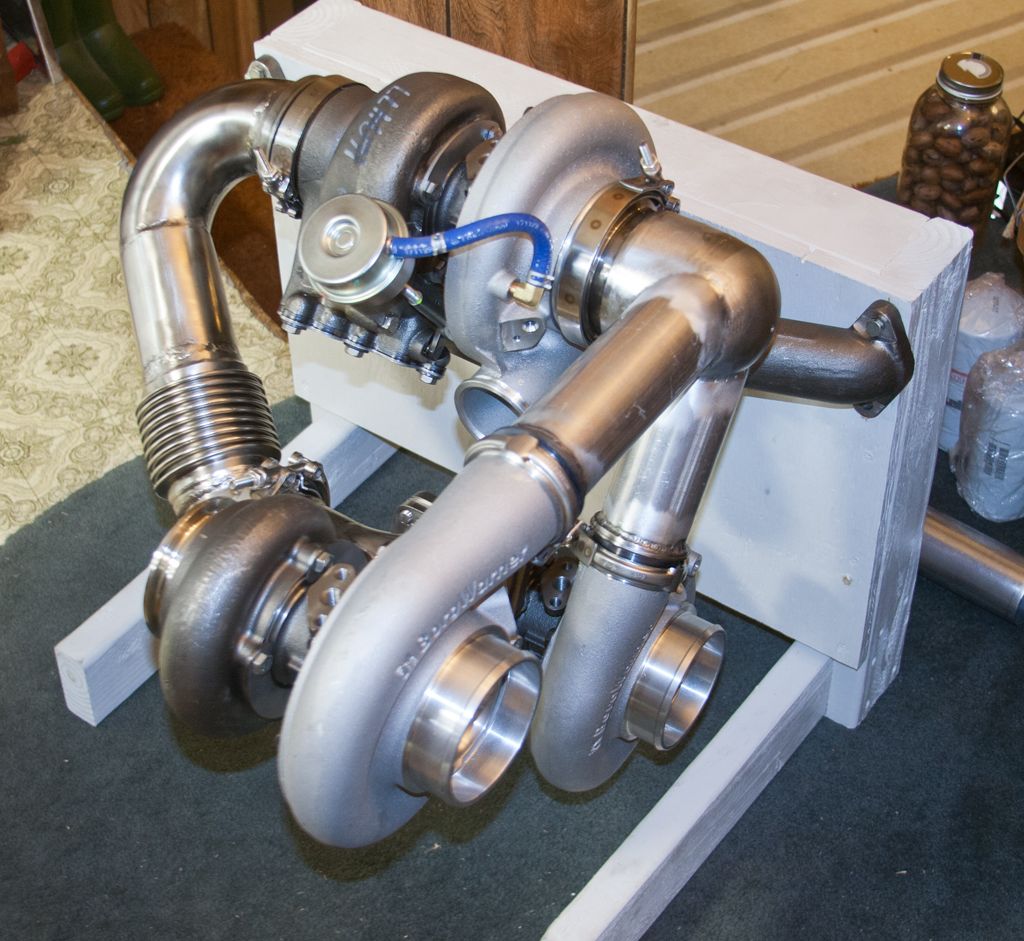

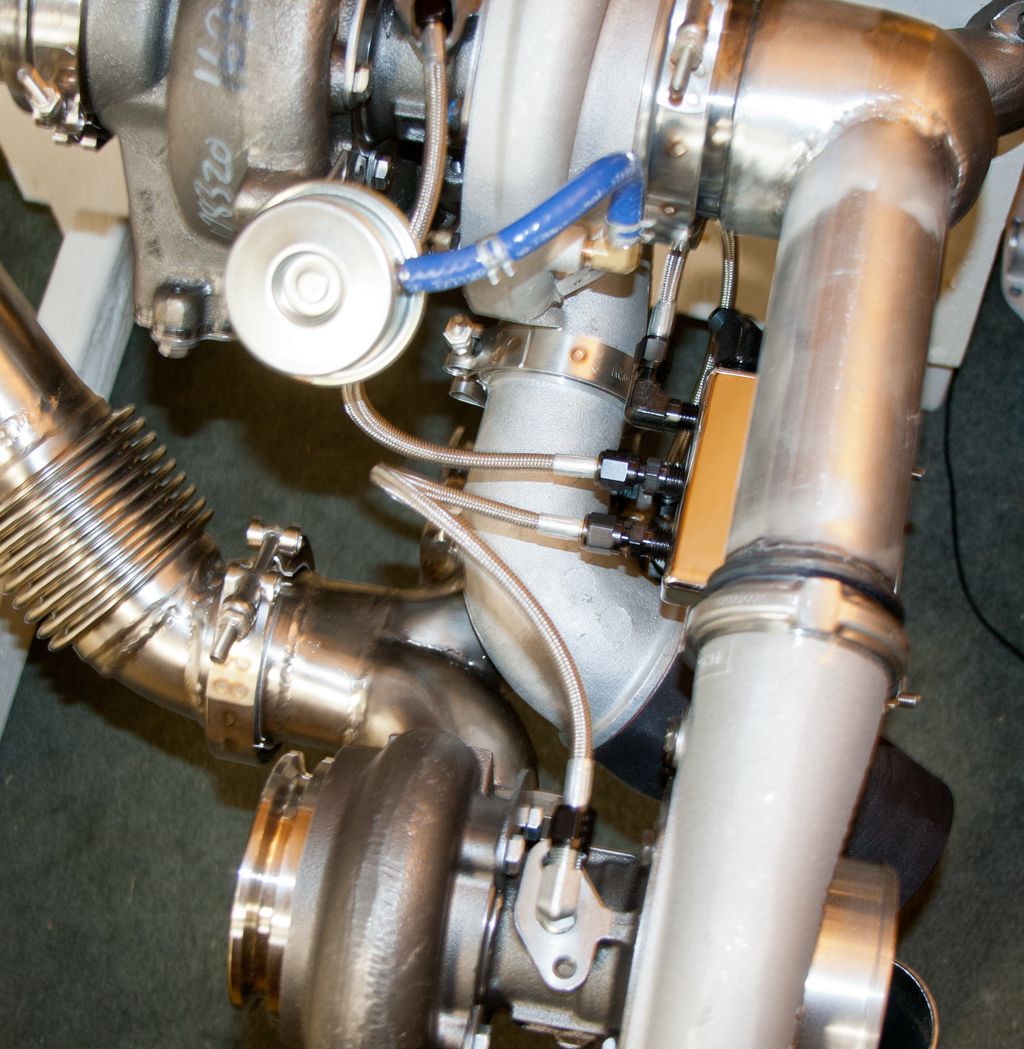

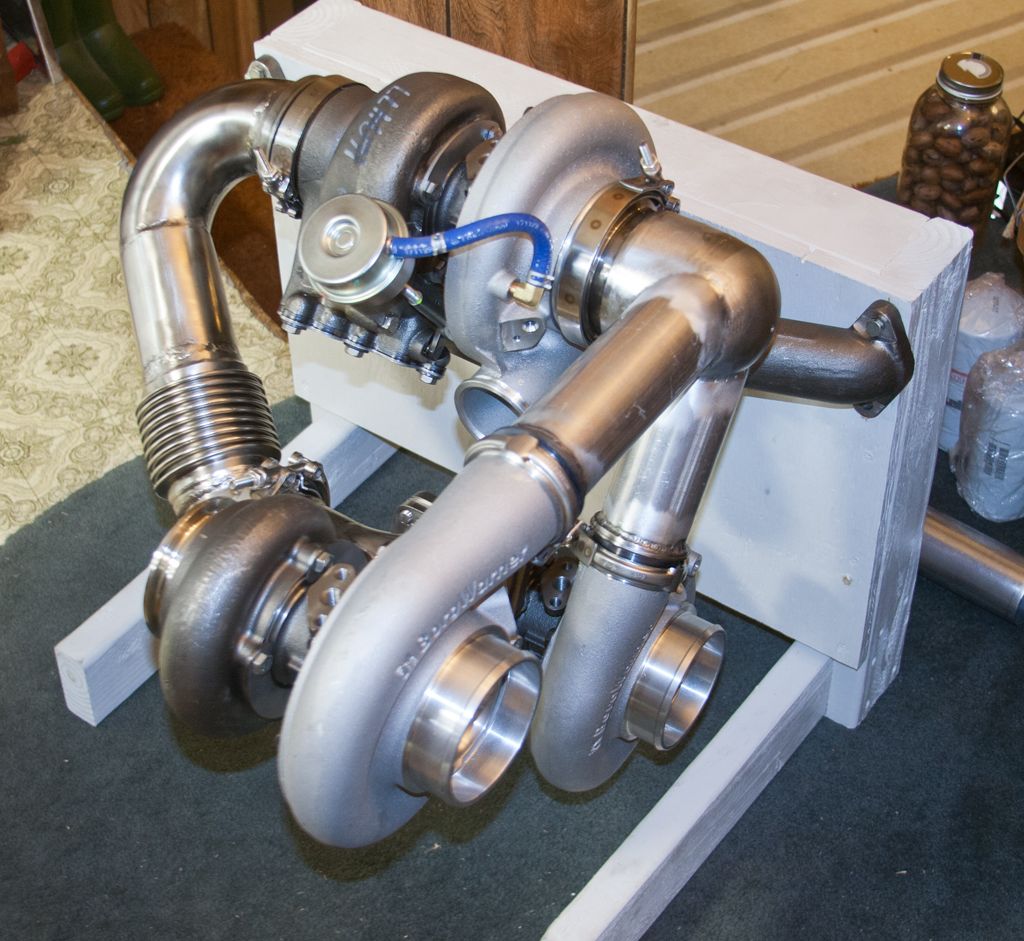

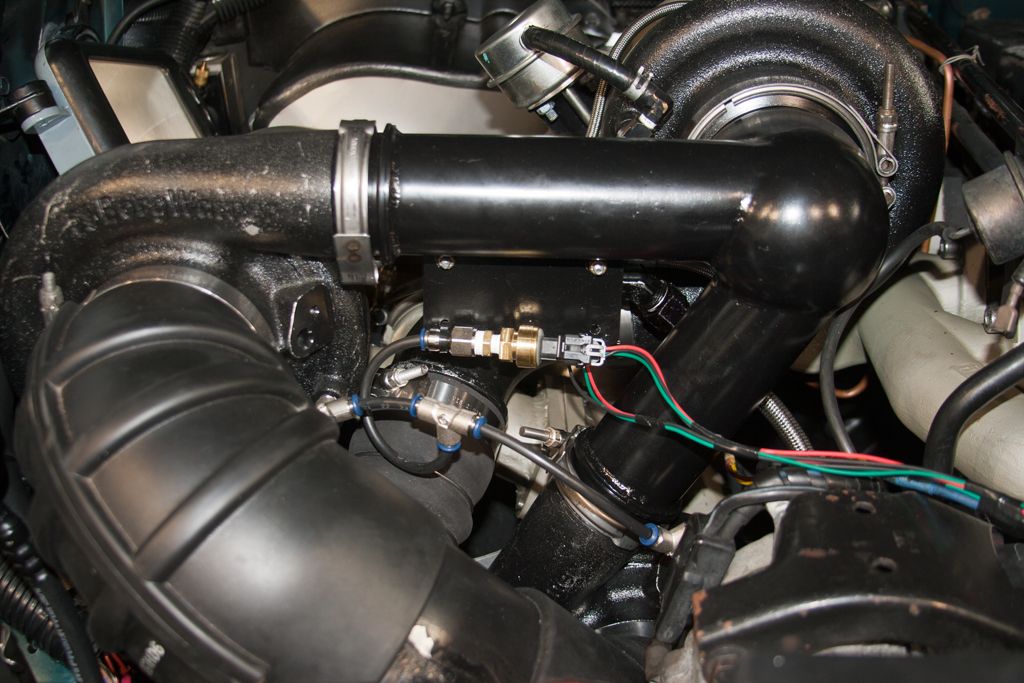

So, I got three S362sxe's. Two with a 12cm exhaust housing playing into the third with a 14cm waste-gated housing.

To keep the heat in the exhaust gases, all the hot-stuff is 14ga 304 stainless steel. All plumbing connections are by way of V-Band clamps.

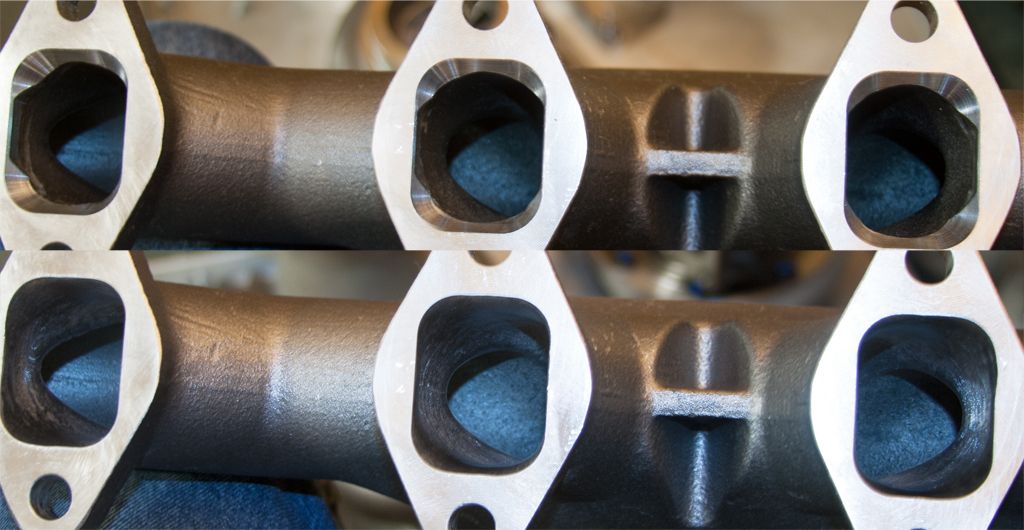

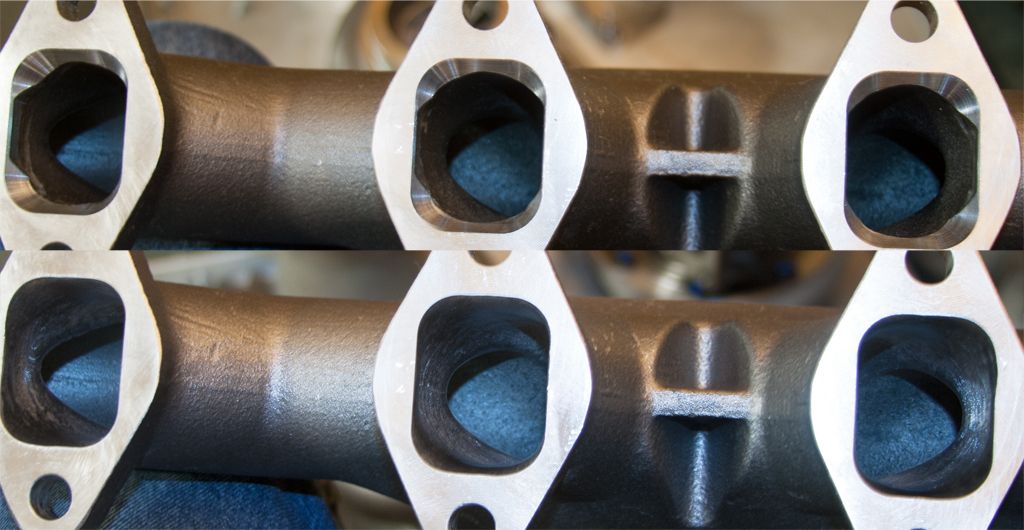

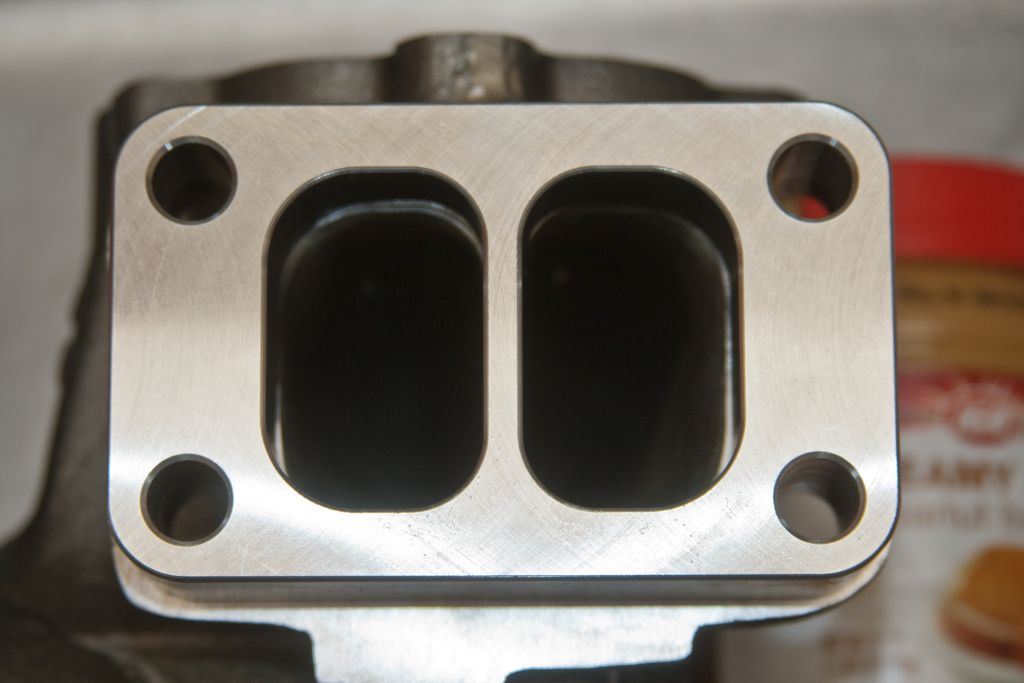

Got a SD exhaust manifold and cleaned up the ports a little:

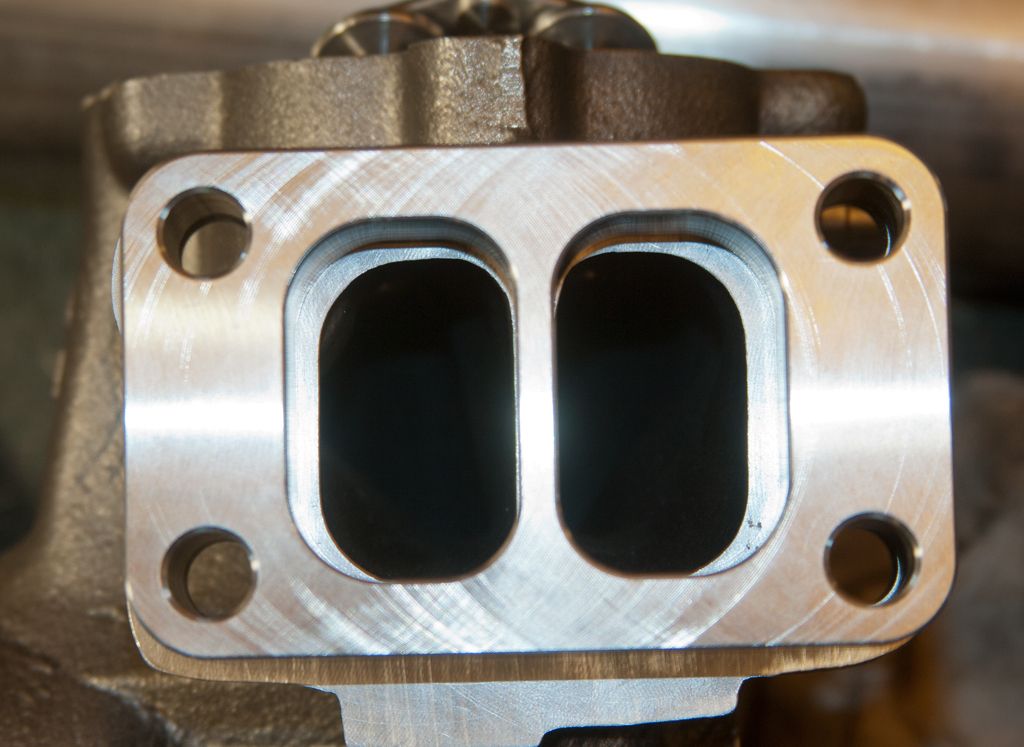

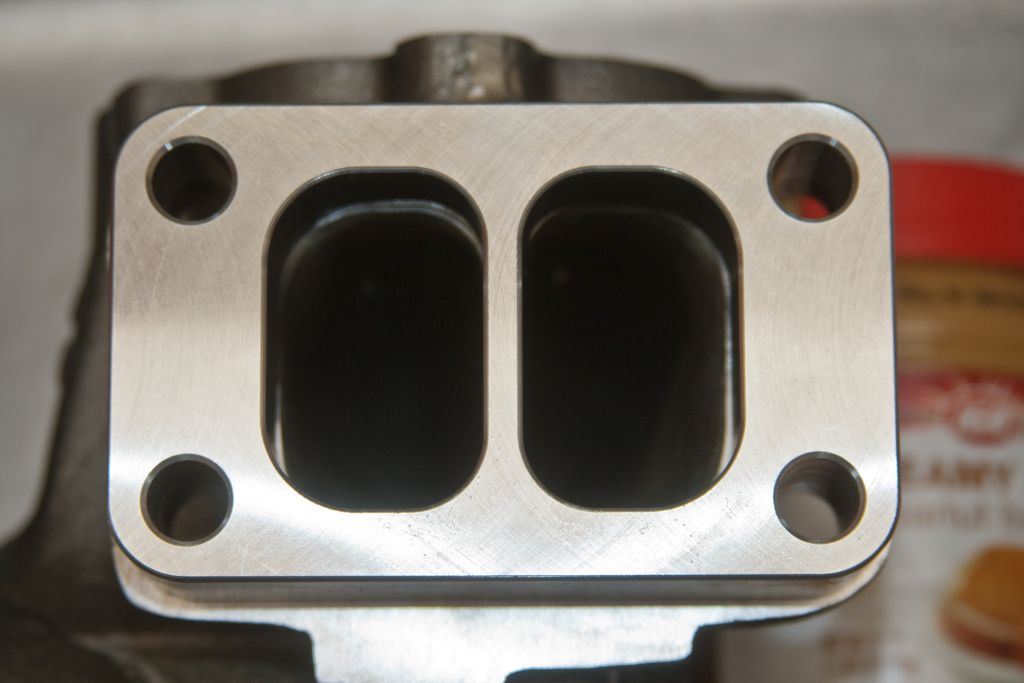

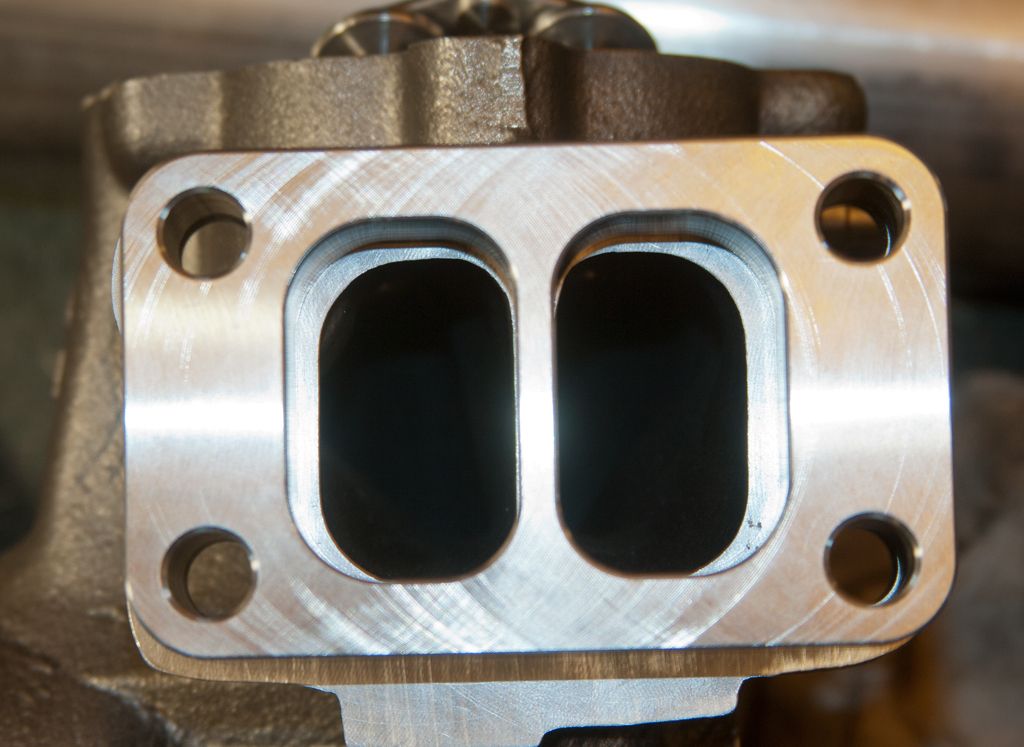

Port-matched all the plumbing including exhaust housings:

Made a Wye-Pipe for the primaries:

The hot-feed from the secondary includes a bellow to accommodate movement:

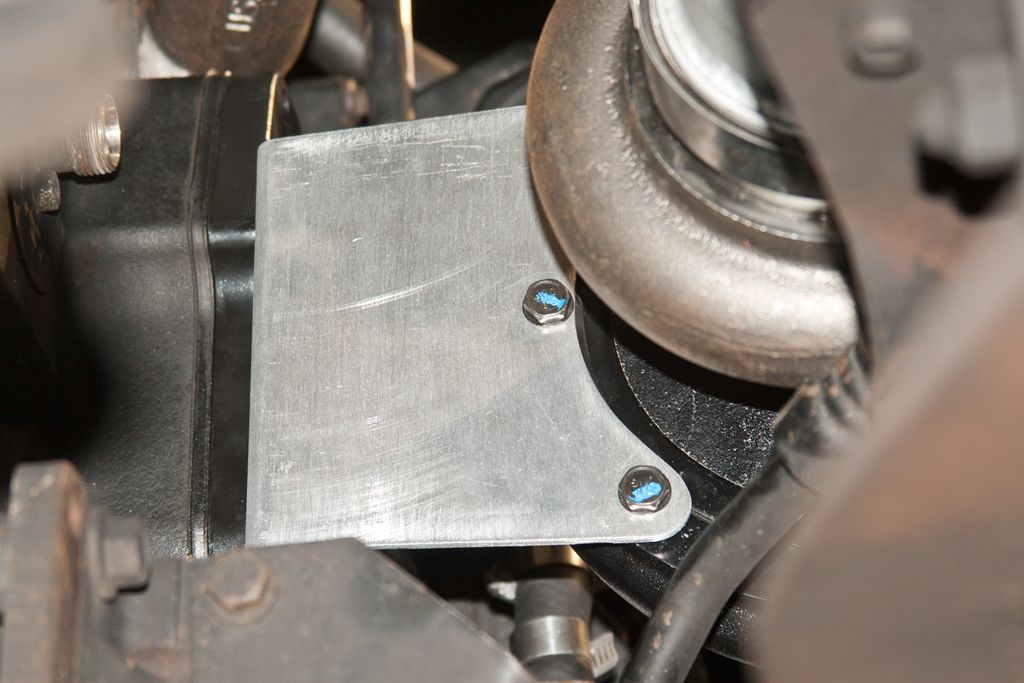

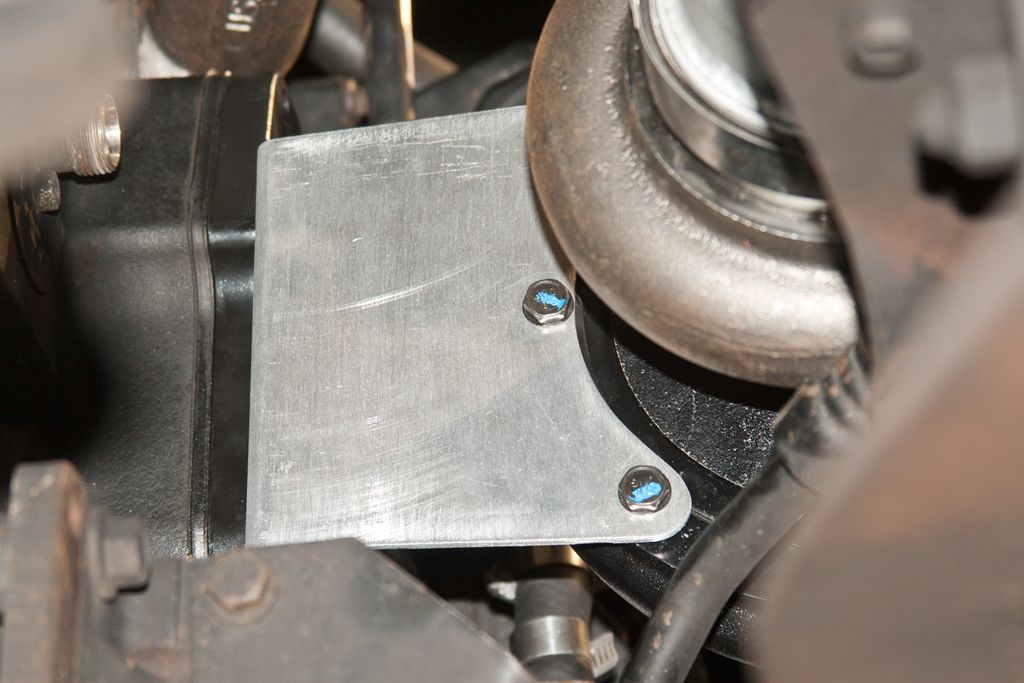

The primaries are supported from the block with bracketry I made from a 20mph sign:

Made a Wye-pipe for the cold-side. It includes an internal turning-vane:

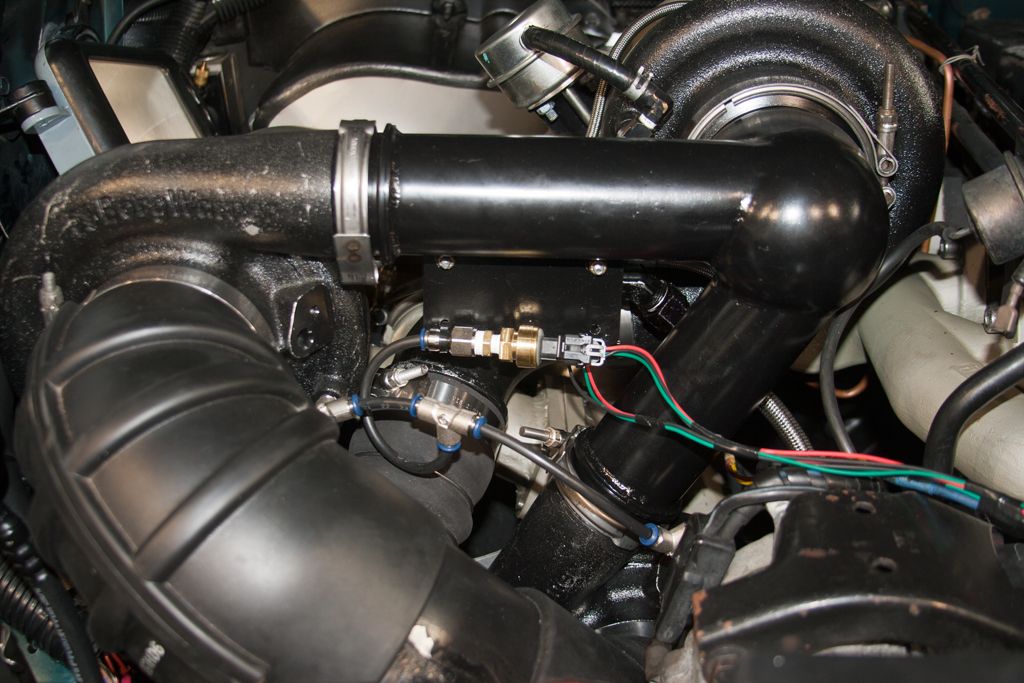

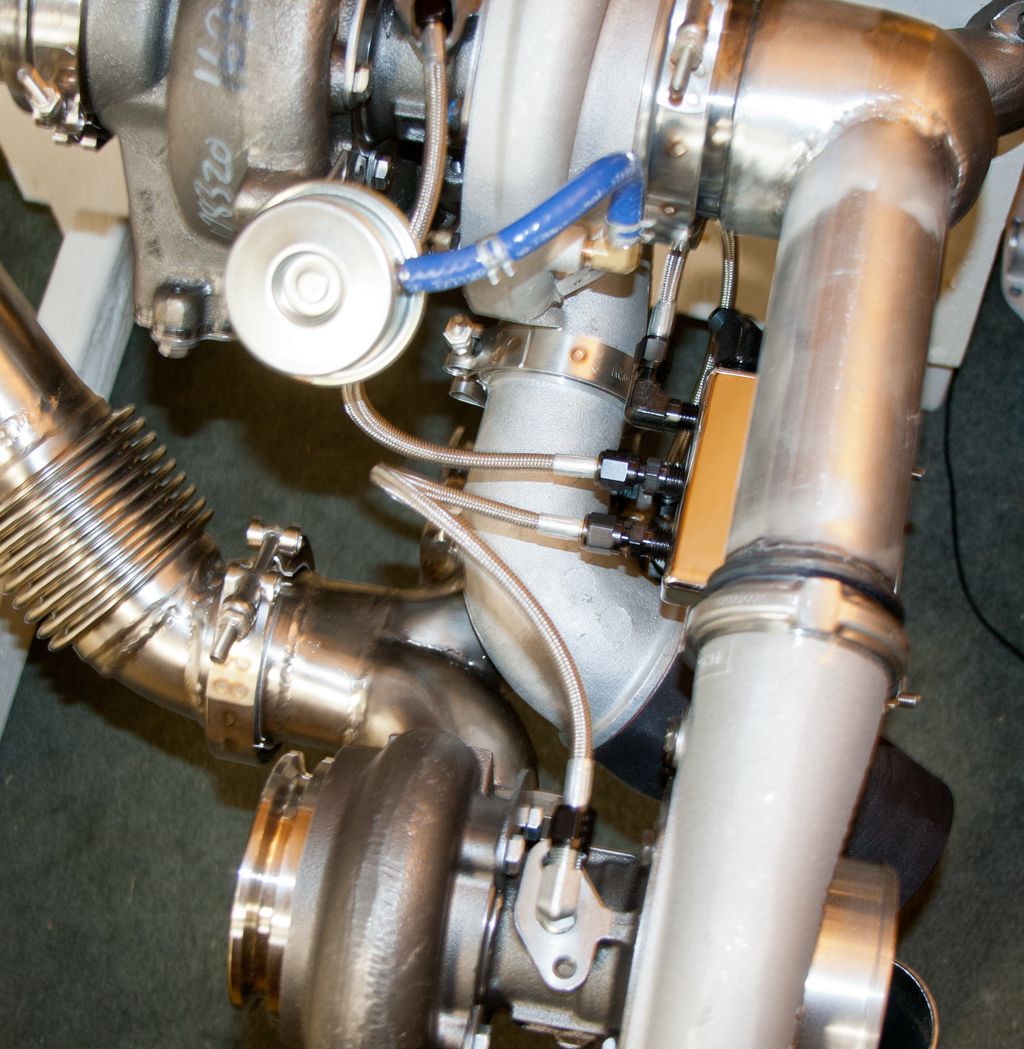

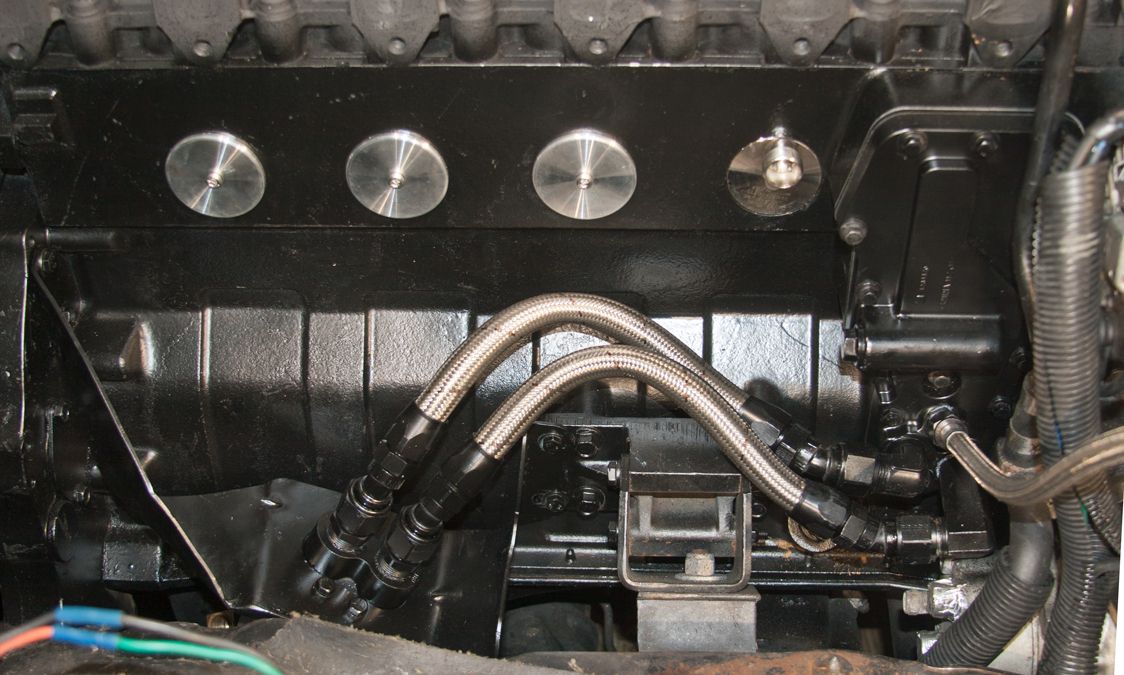

To lube the turbos, I made a manifold for them. AN8 supply with AN4s for each turbo:

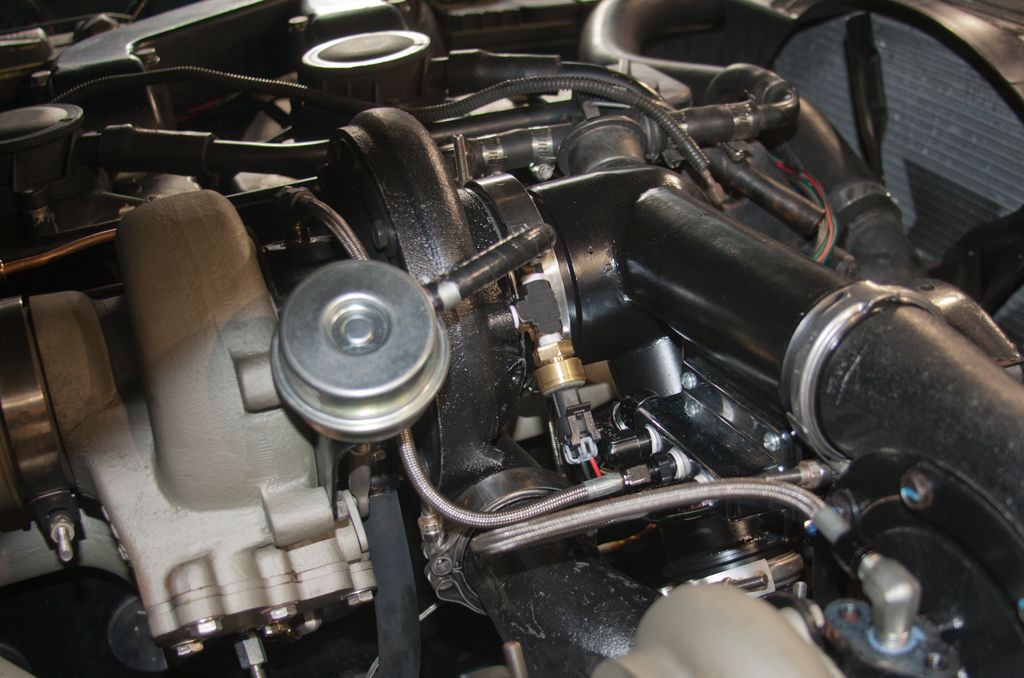

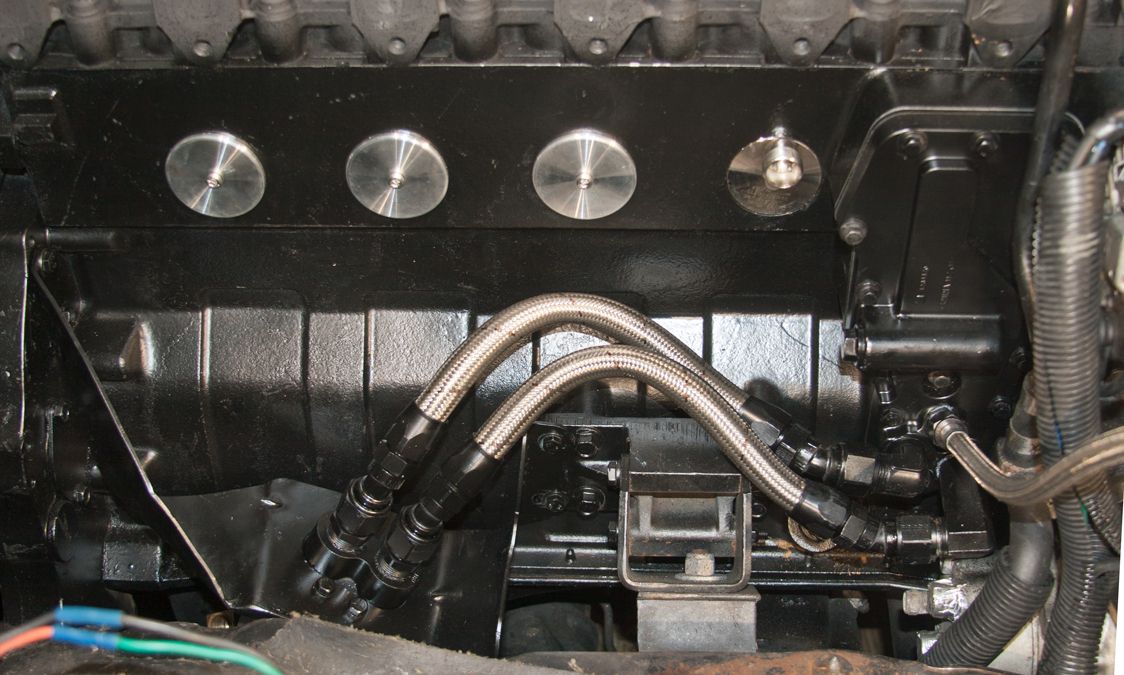

To make the stuff fit under the hood, I had to move the engine oil filter. So I made a bracket, modified a marine oil-cooler cover-plate, and connected it all with AN12 (I think it is) plumbing:

I had to make the exhaust plumbing as I wanted it all 5".

3" off the primaries, It was fun!:

With a number of trips under the truck, I got a 5" down-pipe out of the engine bay, and past the trans/transfer-case (16" of 5" SS triple-flex was included):

On the street, I run a very large, very quiet muffler. I also run a temporary stack in the bed for raceday. So, I made a Wye-pipe that goes just past the transfercase . . . :

A 12" piece of 5" SS triplelock flex connects the bed stack turnup:

Prior to installing the mess (for the almost final time :doh I ceramic-coated the inside and outside of all the hot-stuff:

I ceramic-coated the inside and outside of all the hot-stuff:

I've got a homemade cold-air intake, I connected it to the primaries via a 6" rubber 90* that turns into two 6" to 5" 90*s:

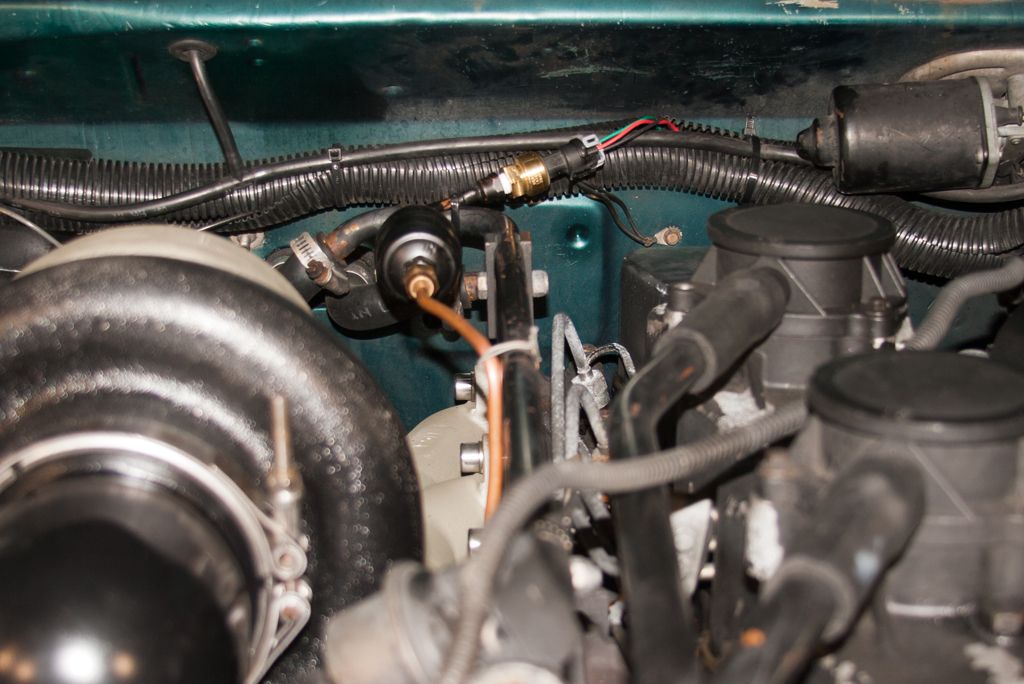

In order to keep the AC, I had to remake the refrigerant lineset so it'd fit to my liking (fittings shown here):

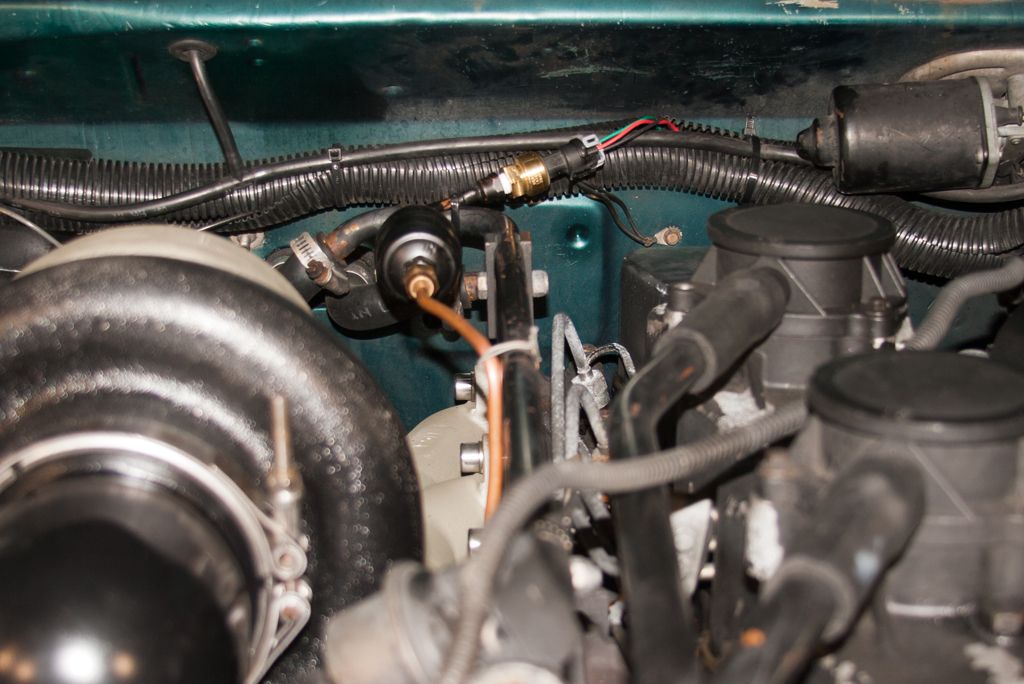

To keep up with the pressures and stuff, I installed sensors on everything (ISSPRO Performax system):

Back-pressure . .

Primaries . ..

I bought my '93 W250 CC new in late November of '93.

Took to playing at the local 8th mile T&T some years ago now. I've been building up the 12mm VE fueled engine slowly. Was running an S362 over an HT3B up until recently when the bearings of the 3B got too loose. I'd upsized the injectors a year or so before and sorely needed more air then.

Anyhoo, the 3B failing had me get on with moving more air.

The 3B is supposedly good for right at 80lbs/min. I figured around 150lbs/min out to cool the fuel I'm currently moving.

So, I got three S362sxe's. Two with a 12cm exhaust housing playing into the third with a 14cm waste-gated housing.

To keep the heat in the exhaust gases, all the hot-stuff is 14ga 304 stainless steel. All plumbing connections are by way of V-Band clamps.

Got a SD exhaust manifold and cleaned up the ports a little:

Port-matched all the plumbing including exhaust housings:

Made a Wye-Pipe for the primaries:

The hot-feed from the secondary includes a bellow to accommodate movement:

The primaries are supported from the block with bracketry I made from a 20mph sign:

Made a Wye-pipe for the cold-side. It includes an internal turning-vane:

To lube the turbos, I made a manifold for them. AN8 supply with AN4s for each turbo:

To make the stuff fit under the hood, I had to move the engine oil filter. So I made a bracket, modified a marine oil-cooler cover-plate, and connected it all with AN12 (I think it is) plumbing:

I had to make the exhaust plumbing as I wanted it all 5".

3" off the primaries, It was fun!:

With a number of trips under the truck, I got a 5" down-pipe out of the engine bay, and past the trans/transfer-case (16" of 5" SS triple-flex was included):

On the street, I run a very large, very quiet muffler. I also run a temporary stack in the bed for raceday. So, I made a Wye-pipe that goes just past the transfercase . . . :

A 12" piece of 5" SS triplelock flex connects the bed stack turnup:

Prior to installing the mess (for the almost final time :doh

I've got a homemade cold-air intake, I connected it to the primaries via a 6" rubber 90* that turns into two 6" to 5" 90*s:

In order to keep the AC, I had to remake the refrigerant lineset so it'd fit to my liking (fittings shown here):

To keep up with the pressures and stuff, I installed sensors on everything (ISSPRO Performax system):

Back-pressure . .

Primaries . ..

Last edited: