joestewart

New member

I am taking measurements to determine the thickness of the #10 thrust bearing plate that I should use.

I am using tool #6311 as a straight edge. I have already measured the thickness of my #6311 and it is 0.5 inches, as it should be.

I took four measurements at 90 degrees apart, as detailed in the ASTG manual.

My measurements are: 1.965, 1.969, 1.9705 and 1.9715.

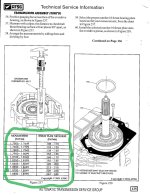

These measurements fall OUTSIDE OF ALL THE RANGES GIVEN ON PAGE 135 OF THE ASTG MANUAL (see attached image).

And of course, the ASTG manual does not tell you what to do when this happens.

I am thinking that this measurement, in part, depends on stack thickness. I used 10 frictions and 9 steels.

Otherwise, I'm pretty sure that I installed everything correctly.

I did a quick internet search. I'm sure the answer to this question has been posted a million times, but I'm having trouble readily locating a relevant thread.

Does anyone have any suggestions as to what the proper remedial action should be in this scenario?

I am using tool #6311 as a straight edge. I have already measured the thickness of my #6311 and it is 0.5 inches, as it should be.

I took four measurements at 90 degrees apart, as detailed in the ASTG manual.

My measurements are: 1.965, 1.969, 1.9705 and 1.9715.

These measurements fall OUTSIDE OF ALL THE RANGES GIVEN ON PAGE 135 OF THE ASTG MANUAL (see attached image).

And of course, the ASTG manual does not tell you what to do when this happens.

I am thinking that this measurement, in part, depends on stack thickness. I used 10 frictions and 9 steels.

Otherwise, I'm pretty sure that I installed everything correctly.

I did a quick internet search. I'm sure the answer to this question has been posted a million times, but I'm having trouble readily locating a relevant thread.

Does anyone have any suggestions as to what the proper remedial action should be in this scenario?