BC847

New member

Greetings Earthlings.

I bought my 1993 Dodge/Cummins W250 new, in 1993. Right at 175,000 miles on it now.

A few years after buying it, I broke a tooth off the pinion gear in the rear OEM DANA70 (dunno how) that includes the OEM Power-Loc differential. I replaced the ring & pinion and have since put perhaps 140,000 miles on that.

As a Predictive Maintenance thing, I recently rebuilt the differential including new clutches/steels, spider-gear assembly, new Ring & Pinion as well as all associated bearings w/races (ALL Spicer/DANA brand stuff). It was filled with the correct lube-oil and the Spicer Limited-Slip friction modifier stuff.

All was well for perhaps 100 miles or so and I noticed the differential was chattering with making a turn. It was as though I hadn't used the friction modifier. So I put another dose of the modifier in. With that it seemed to straighten-up for a while.

So, I drove it for a while and noticed the rumbling/shuddering continued with making turns.

Went to the track this past Thursday and made a couple of passes. The second had me break traction coming out of the hole resulting in **** jumping all around till I could get off it. The track and tires were cold so that didn't help, but it got me to thinking: That shuddering rear-end, did that actually cause it?

So, I took it apart today to have a look.

Damnit!

CSI mode ON.

I've photographed things as they came apart to see if I had inadvertently assembled something wrong . . . ..

Removing the diff and setting it on the floor shows I have the Spider-gear shafts properly seated in the proper grooves/notches of the carrier . . . .

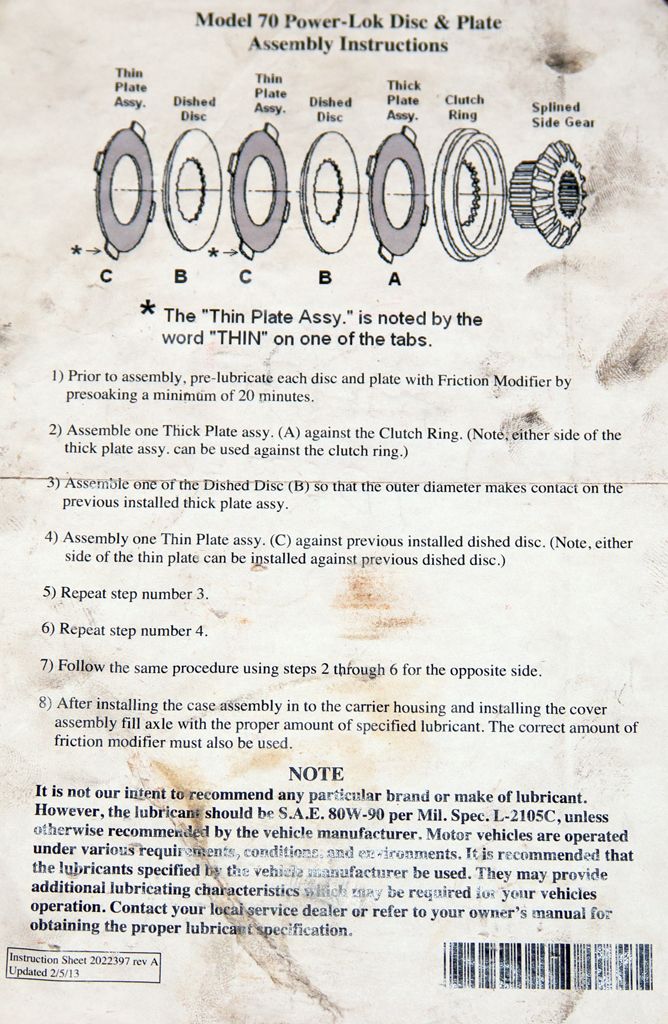

I've layed things out showing how I assembled it back then. This is looking at one of the two clutch-pacs . . .. .

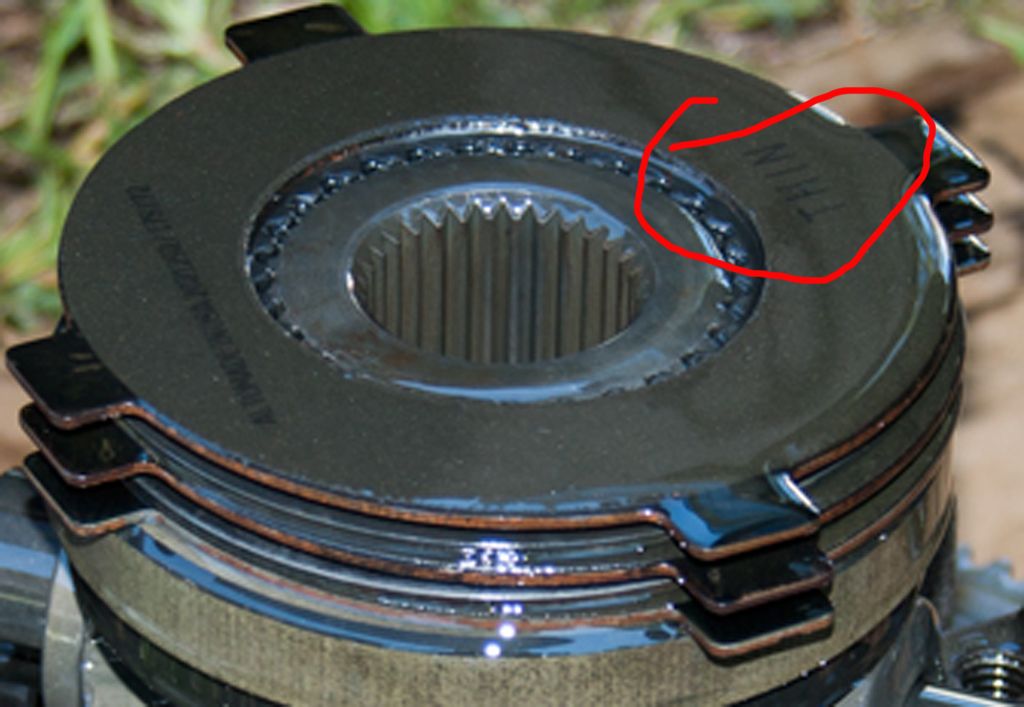

Understanding the clutch steels are dished / concaved, I can see where the steels come into contact with the clutch disks. (See red dots) Notice the streaks of wear on the steels, match the neighboring clutch. It's polished the steels, and heated the mating clutch area enough that one can see perhaps heat related damage to the opposite side of the clutches.

The dished steels have cut into the clutches such that it cut rings into the clutch material, on both sides of the clutches, on the inner, or outter diameter, pending which side of the dished steel you're looking at.

You can clearly see the cutting of the clutch material (Green Dot). One can see where the cut-free clutch material is separating from the thing (Red Dot) . . .

So, now I've got this mess floating around in the lube-oil . . .. It's strips of clutch material . . . .

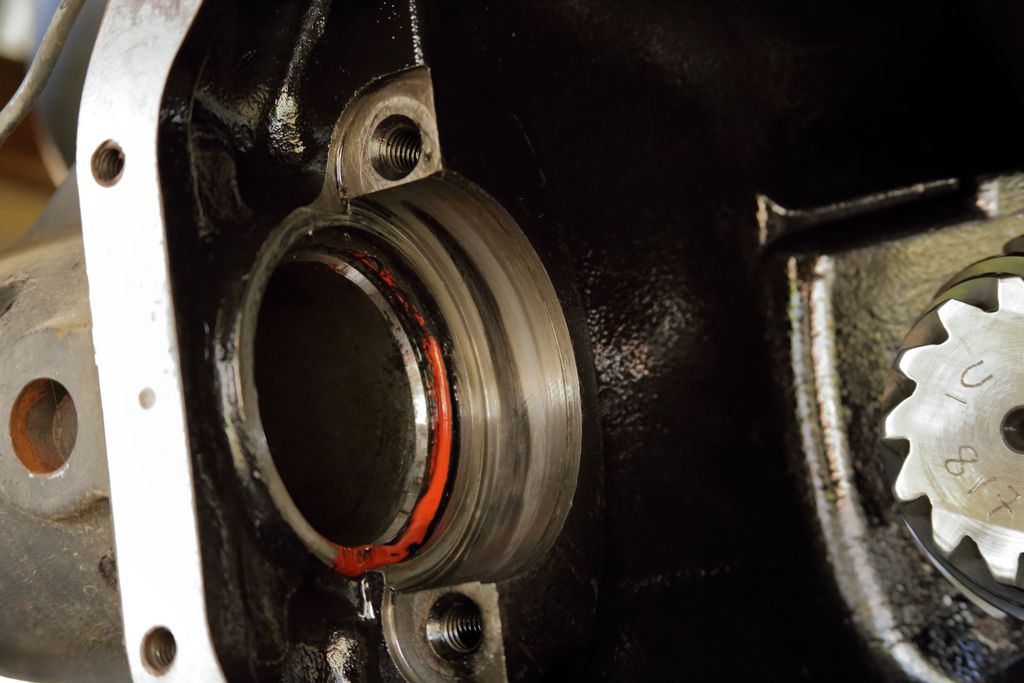

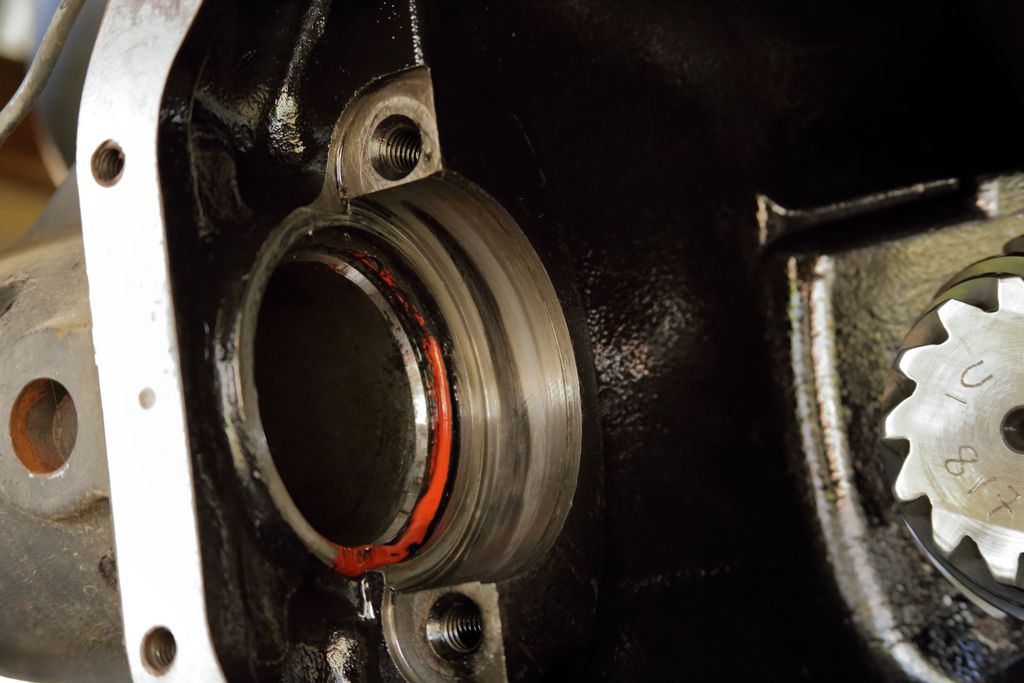

I figure that crap has gotten into the carrier bearings, momentarily jammed them, forcing them to spin the races in the axle-housing . . . . .

Typical of both sides . . .

Typical of both sides . . .

Futher, I figure that same clutch material has gotten in the gears and being abrasive in nature, has scored the gear's teeth . . . . Pinion-gear . . . .

Spider-gears . . . .

- How did the clutch-disks get cut up? I'm wondering if there was not enough preload on the clutch-packs? But then I don't know if such wear is common for dished clutch-pack elements. . . . . ?

What can I do to correct such so as not to have it happen again?

- That free-floating abrasive clutch material getting in the gears, has it caused fatal damage?

Is the differential housing now ruined with the carrier bearing mounts being scored/wallowed out?

Seven of the ten voices in my head are saying I'm screwed, need to look for a new rear axle.

Are the voices wrong?

Crap. :bang

I bought my 1993 Dodge/Cummins W250 new, in 1993. Right at 175,000 miles on it now.

A few years after buying it, I broke a tooth off the pinion gear in the rear OEM DANA70 (dunno how) that includes the OEM Power-Loc differential. I replaced the ring & pinion and have since put perhaps 140,000 miles on that.

As a Predictive Maintenance thing, I recently rebuilt the differential including new clutches/steels, spider-gear assembly, new Ring & Pinion as well as all associated bearings w/races (ALL Spicer/DANA brand stuff). It was filled with the correct lube-oil and the Spicer Limited-Slip friction modifier stuff.

All was well for perhaps 100 miles or so and I noticed the differential was chattering with making a turn. It was as though I hadn't used the friction modifier. So I put another dose of the modifier in. With that it seemed to straighten-up for a while.

So, I drove it for a while and noticed the rumbling/shuddering continued with making turns.

Went to the track this past Thursday and made a couple of passes. The second had me break traction coming out of the hole resulting in **** jumping all around till I could get off it. The track and tires were cold so that didn't help, but it got me to thinking: That shuddering rear-end, did that actually cause it?

So, I took it apart today to have a look.

Damnit!

CSI mode ON.

I've photographed things as they came apart to see if I had inadvertently assembled something wrong . . . ..

Removing the diff and setting it on the floor shows I have the Spider-gear shafts properly seated in the proper grooves/notches of the carrier . . . .

I've layed things out showing how I assembled it back then. This is looking at one of the two clutch-pacs . . .. .

Understanding the clutch steels are dished / concaved, I can see where the steels come into contact with the clutch disks. (See red dots) Notice the streaks of wear on the steels, match the neighboring clutch. It's polished the steels, and heated the mating clutch area enough that one can see perhaps heat related damage to the opposite side of the clutches.

The dished steels have cut into the clutches such that it cut rings into the clutch material, on both sides of the clutches, on the inner, or outter diameter, pending which side of the dished steel you're looking at.

You can clearly see the cutting of the clutch material (Green Dot). One can see where the cut-free clutch material is separating from the thing (Red Dot) . . .

So, now I've got this mess floating around in the lube-oil . . .. It's strips of clutch material . . . .

I figure that crap has gotten into the carrier bearings, momentarily jammed them, forcing them to spin the races in the axle-housing . . . . .

Typical of both sides . . .

Typical of both sides . . .

Futher, I figure that same clutch material has gotten in the gears and being abrasive in nature, has scored the gear's teeth . . . . Pinion-gear . . . .

Spider-gears . . . .

- How did the clutch-disks get cut up? I'm wondering if there was not enough preload on the clutch-packs? But then I don't know if such wear is common for dished clutch-pack elements. . . . . ?

What can I do to correct such so as not to have it happen again?

- That free-floating abrasive clutch material getting in the gears, has it caused fatal damage?

Is the differential housing now ruined with the carrier bearing mounts being scored/wallowed out?

Seven of the ten voices in my head are saying I'm screwed, need to look for a new rear axle.

Are the voices wrong?

Crap. :bang

Last edited: