1320Cummins

2G Collector

This box is awesome! please continue with it even if two more pistons are involved!

I know, time for an update if you're running a second quicker! The 60ft actually looked pretty dang good for a 8000lb 4 banger too :Cheer:

Sweet build. I love anything 4BT powered!

Haha the miata never had a chance! Where are you guys seeing the video?

Ok which one of you is this?? - Competition Diesel.Com - Bringing The BEST Together

What turbo's are you using if you don't mind me asking ? Similar as Khaoskustoms ? 58mm and 71mm inducer ?

How much does that thing weigh?

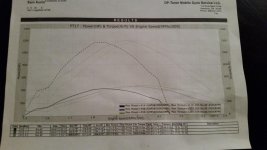

Thanks, we have been using your build thread as sort of a guide on some of the stuff we have been doing, so we appreciate the support. Be ready though because we're coming for that 550hp lol

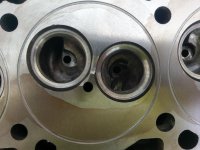

No more blown head gaskets and time for the next goal of breaking into the 13’s.

Did that last pass vs the Toyota not say 13.89?

.