CHDiesel

New member

Problem with V8s is pulses are not equally timed, so they will never be as efficient as inline 6.

Okay... that's a topic for another thread.

I just want an answer to the questions asked.... nothing else.

Problem with V8s is pulses are not equally timed, so they will never be as efficient as inline 6.

Okay... that's a topic for another thread.

I just want an answer to the questions asked.... nothing else.

clearly mapped twins will suit that v8 best....oke:

he doesnt want bro science but thinks sizes are the most important factor rather than design...

Again.....

Use Matchbot!

this thread isnt about that. Its about science

I didn't start this thread just to find a turbo, or I wouldnt have just asked that. I'm curious what is going on in the turbine of a turbo, and how different things effect that.

The turbine spins.......

The man from across the pond answered your question!

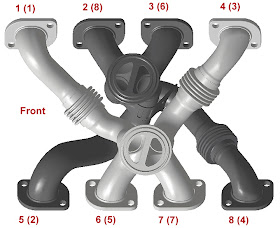

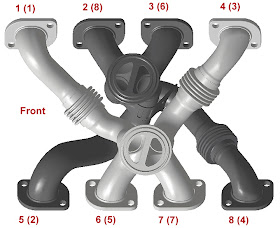

The only way to stay on top of a charger with a V design as efficiently as an inline would be a cross bank manifold design similar to what's found on BMW twin turbo motors. It minimizes turbulance while increasing spool from equal pulses do to the runners feeding the turbos in firing order.

K... I'm not looking for how to use the exhaust pulses more efficiently. A few other brands use a flatplane crank to even out the V8 pulses though. The firing order of Duramax and PStroke just needs a single crossover from each bank.

Give me the pulse volume, gas velocity, A/R volume, peak pressure, pressure dwell time in degrees, outlet flow at exhaust density for different outlet sizes, straight scroll angle. I'll do the math myself, those are the only things I want out of this thread.

I was hoping some people already had, and they would be the ones to chime in.

So what I want to know is what hot side flow ratings are enough for what horsepower levels.

Also turbine specs in relation to compressor specs is topic for another thread.

K... I'm not looking for how to use the exhaust pulses more efficiently. A few other brands use a flatplane crank to even out the V8 pulses though. The firing order of Duramax and PStroke just needs a single crossover from each bank.

Give me the pulse volume, gas velocity, A/R volume, peak pressure, pressure dwell time in degrees, outlet flow at exhaust density for different outlet sizes, straight scroll angle. I'll do the math myself, those are the only things I want out of this thread.

I was hoping some people already had, and they would be the ones to chime in.

Do you have this book: Turbocharging fundamentals , by Nicholas C. Baines ? I recommend it, lots about turbines also, but very advanced theory, I understand maybe 50% of it but it helped a lot to understand turbocharging.