- Joined

- Jan 22, 2007

- Messages

- 32,178

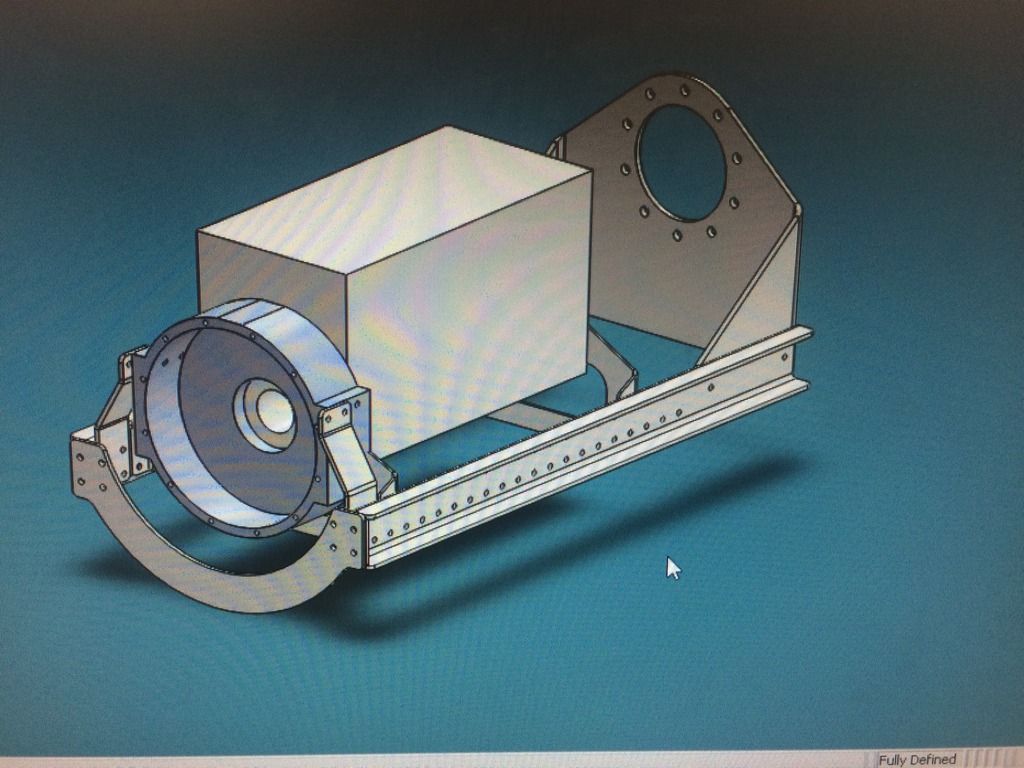

I'm getting ready to go pick up a '82 DT466B 180hp motor to put in this dump truck. I think it needs new rings as it burns some oil. Not sure 'til I break it down. I'm shooting for the 250 hp mark with it with a little pump work and new nozzles. I hope the turbo is good and is an HX-50 or something comparable. I'm still learning on this thing.

Anywho....I'm googling stands now but if any of you have dimensions or ideas, I'd love to hear them. Not sure yet how heavy this SOB is gonna be.

:thankyou2:

Anywho....I'm googling stands now but if any of you have dimensions or ideas, I'd love to hear them. Not sure yet how heavy this SOB is gonna be.

:thankyou2:

Last edited: