CTDYoungGun

Seth- Fuel Injection Guy

- Joined

- Aug 7, 2007

- Messages

- 1,568

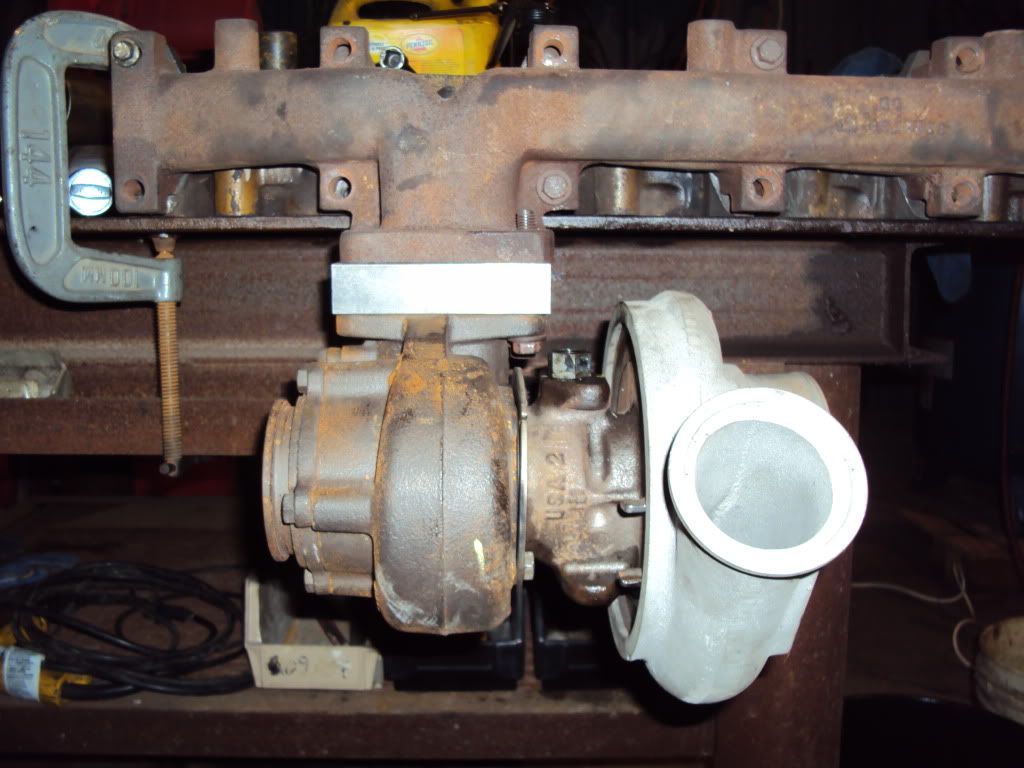

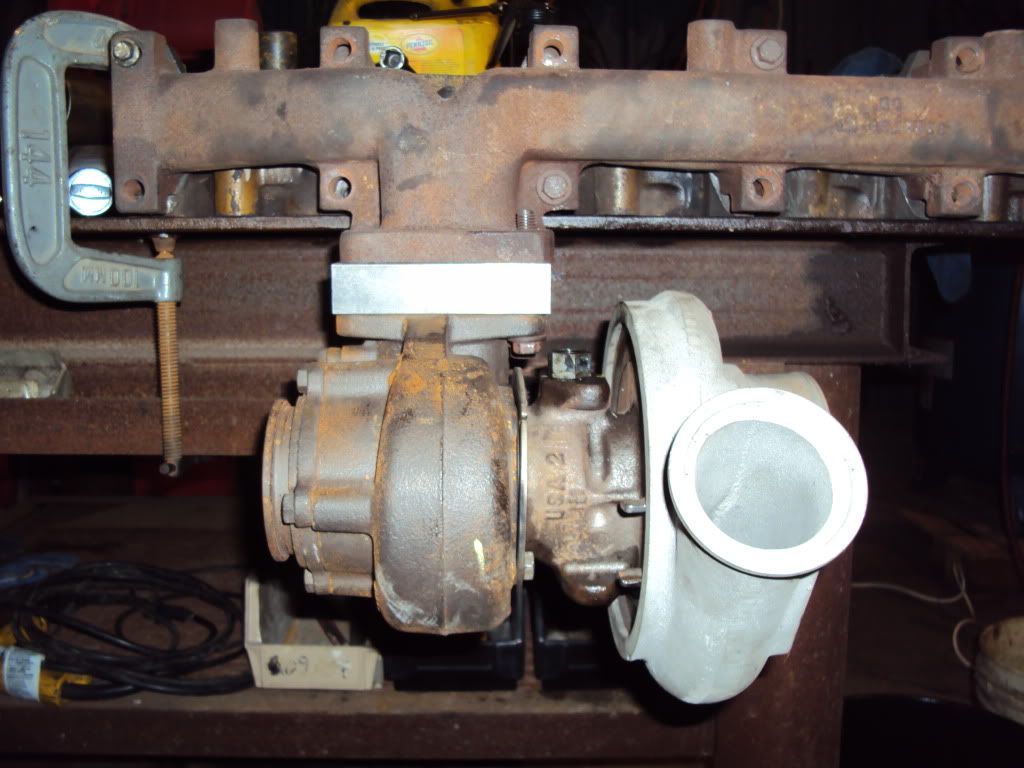

As promised, here's quite a few pictures of my triple turbo build. The primaries will be hy35's with 9cm housings and the primary is an hx35/40 hybrid with a heavily ported 12cm housing. I also built in a spacer for an external gate to be added in the future to gate around the primary into the hot-pipe.

The hot-pipe is all schedule 40 pipe and the "split" is built from modified 2x3" 1/4" wall rectangular tubing.

The down-pipes, cold pipe, and inter-cooler pipe are all built from a 3" ultimate builder kit from Columbia River Mandrel Bending. They are mild steel 16 gauge.

I made all my own turbo flanges and discharges to save some coin. I'm by no means a great fabricator, but I think it turned out decent.

No, it isn't on the street yet (waiting on turbo oil drain hose) and then I'll be out for round two of testing and driving. The rest of the engine set-up is a pump build and set up by myself (175hp pump, 191's, open holders, 4k kit, custom afc set-up and plate), 5x.014 injectors, 60# valve springs, Valair Sprung Hub dual disk clutch and billet flywheel using big input shaft...

Feel free to cuss and discuss :rockwoot:

The hot-pipe is all schedule 40 pipe and the "split" is built from modified 2x3" 1/4" wall rectangular tubing.

The down-pipes, cold pipe, and inter-cooler pipe are all built from a 3" ultimate builder kit from Columbia River Mandrel Bending. They are mild steel 16 gauge.

I made all my own turbo flanges and discharges to save some coin. I'm by no means a great fabricator, but I think it turned out decent.

No, it isn't on the street yet (waiting on turbo oil drain hose) and then I'll be out for round two of testing and driving. The rest of the engine set-up is a pump build and set up by myself (175hp pump, 191's, open holders, 4k kit, custom afc set-up and plate), 5x.014 injectors, 60# valve springs, Valair Sprung Hub dual disk clutch and billet flywheel using big input shaft...

Feel free to cuss and discuss :rockwoot: