superpsd

New member

I just joined up thought I would show my current project. Blower is an eaton M122 over the turbo on my 7.3 I have upgraded the blower to a VMP generation 2 eaton TVS and added a bypass. I am just running some tunes on the stock injectors currently. Setup makes 1.5 psi @ idle and no more than 5 psi pre turbo. Next up I plan on getting some software to self tune and bigger sticks. I have been driving it daily for about 4 months now.

[ame="http://s127.photobucket.com/user/nicalizel/media/IMAG0545_1_zpsa434a909.jpg.html"]IMAG0545_1_zpsa434a909.jpg Photo by nicalizel | Photobucket[/ame]

[ame="http://s127.photobucket.com/user/nicalizel/media/IMAG06651_zps0a87cf17.jpg.html"]IMAG06651_zps0a87cf17.jpg Photo by nicalizel | Photobucket[/ame]

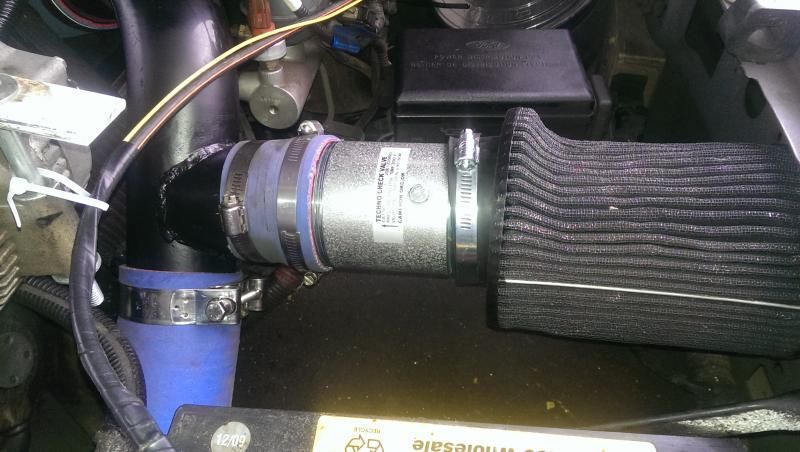

This was the old blower.

[ame="http://s127.photobucket.com/user/nicalizel/media/IMAG05291_zpsa49985c1.jpg.html"]IMAG05291_zpsa49985c1.jpg Photo by nicalizel | Photobucket[/ame]

I daily drive this rig and use it up in the foothills climbing steep logging roads. Maintains pre turbo boost even at 6400 elevation.

[ame="http://s127.photobucket.com/user/nicalizel/media/IMAG0575_1_zps8bc5e3aa.jpg.html"]IMAG0575_1_zps8bc5e3aa.jpg Photo by nicalizel | Photobucket[/ame]

[ame="http://s127.photobucket.com/user/nicalizel/media/IMAG0545_1_zpsa434a909.jpg.html"]IMAG0545_1_zpsa434a909.jpg Photo by nicalizel | Photobucket[/ame]

[ame="http://s127.photobucket.com/user/nicalizel/media/IMAG06651_zps0a87cf17.jpg.html"]IMAG06651_zps0a87cf17.jpg Photo by nicalizel | Photobucket[/ame]

This was the old blower.

[ame="http://s127.photobucket.com/user/nicalizel/media/IMAG05291_zpsa49985c1.jpg.html"]IMAG05291_zpsa49985c1.jpg Photo by nicalizel | Photobucket[/ame]

I daily drive this rig and use it up in the foothills climbing steep logging roads. Maintains pre turbo boost even at 6400 elevation.

[ame="http://s127.photobucket.com/user/nicalizel/media/IMAG0575_1_zps8bc5e3aa.jpg.html"]IMAG0575_1_zps8bc5e3aa.jpg Photo by nicalizel | Photobucket[/ame]