renopker

New member

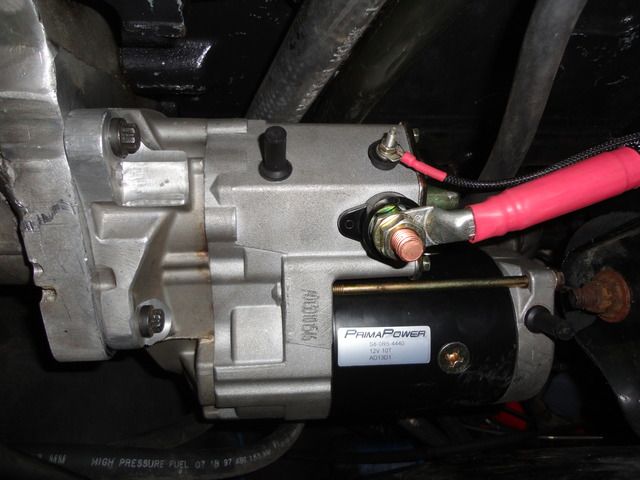

This starter draws 159 amps @ free spin motor speed 3150 RPM or 700 RPM on the pinion

vs 5.9 starter draws 200 amps free spin @ 3000 motor speed.

Current draw @ max power is 921 amps

vs 5.9 Cranking Current draw 450-700

the big starter will turn the motor @ 57.3 RPM

Its all about load that will determine the amp draw speed.

vs 5.9 starter draws 200 amps free spin @ 3000 motor speed.

Current draw @ max power is 921 amps

vs 5.9 Cranking Current draw 450-700

the big starter will turn the motor @ 57.3 RPM

Its all about load that will determine the amp draw speed.