Nor_Cal_Angler

New member

- Joined

- Nov 12, 2009

- Messages

- 221

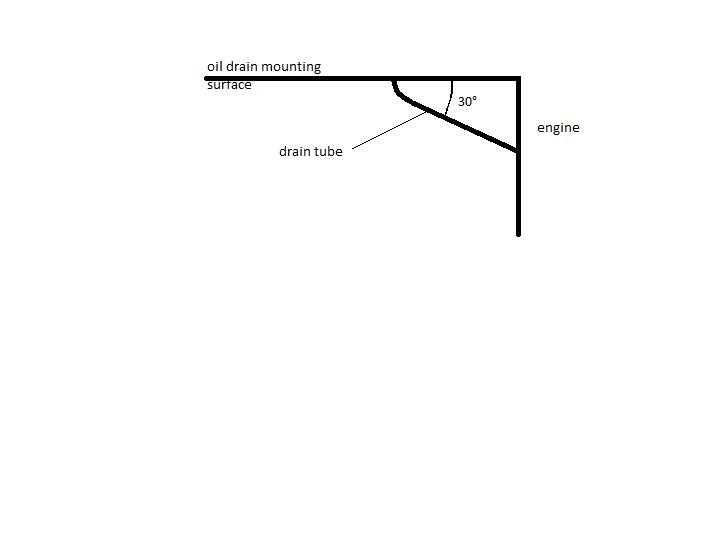

Hey all, going to be doing the VGT swap....I have a simple question for those that have done this and those that have a good working knowledge of turbo install's

I have read from holset that clocking is acceptable but they do not recommend more than a 5 degree rotation off of the verticle location.

This is (according to the writing) in an effort to keep oil free flowing.

What would be the issue if it more than 5 degrees..isn't it pressure fed thorough the turbo..the only time it might come into play is when sitting.

I don't plan on clocking it 90 derees, but for clearance issues, would say 20 degress be ok.

Thoughts welcome....

Jake

I have read from holset that clocking is acceptable but they do not recommend more than a 5 degree rotation off of the verticle location.

This is (according to the writing) in an effort to keep oil free flowing.

What would be the issue if it more than 5 degrees..isn't it pressure fed thorough the turbo..the only time it might come into play is when sitting.

I don't plan on clocking it 90 derees, but for clearance issues, would say 20 degress be ok.

Thoughts welcome....

Jake