Cozze44

Junkman

- Joined

- Feb 9, 2012

- Messages

- 1,315

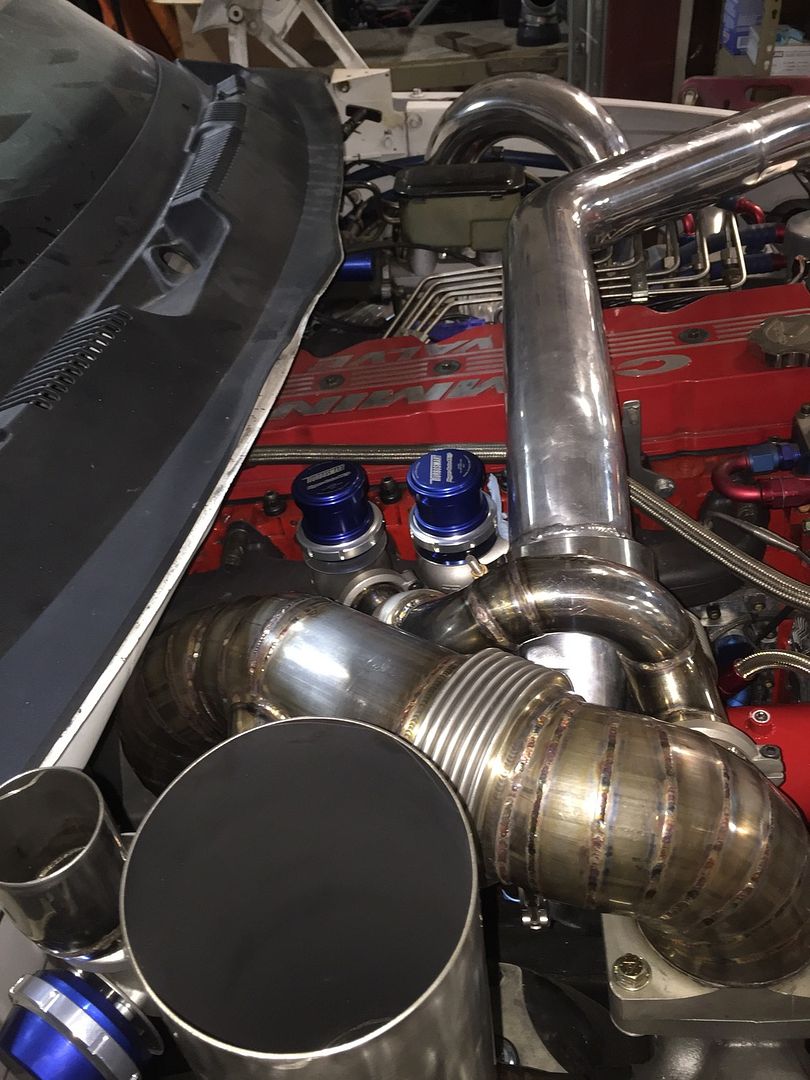

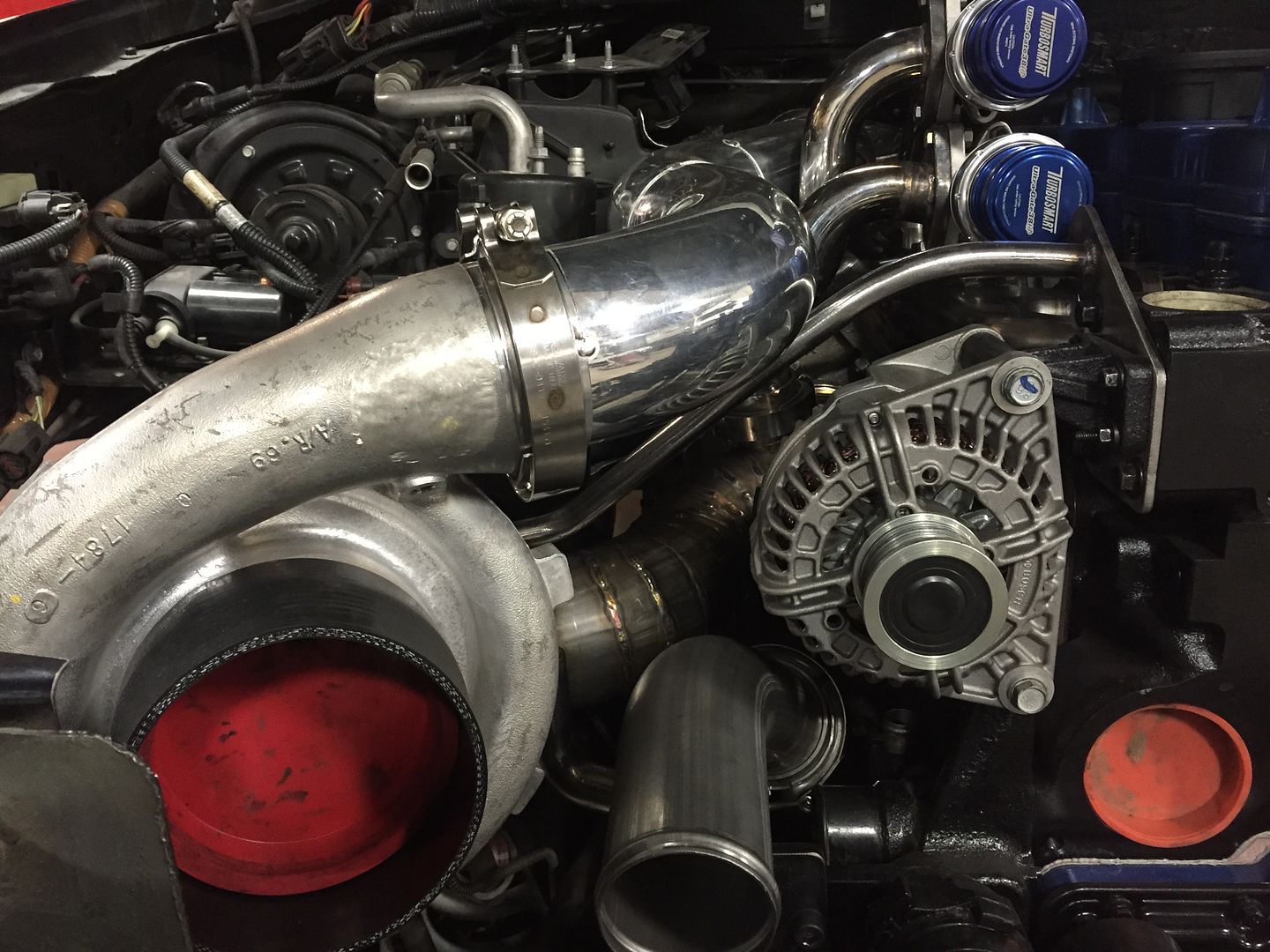

I run 2 Turbosmart 45mm gates around my secondary and 1 around the primary. I've also done quite a few with 38mm Turbosmart gates around the secondary on smaller setups. Depends more on the chargers. I always run the high pressure heads though. That way you can tune them with the springs and they are exactly the same. I've also played with mechanical regulators on them. On the Fummins we moved the oil filter. It did fit, I just didn't want the hot pipe that close to it.

Beautiful work btw! :Cheer: