Cummins12Club

Happy Dinosaur

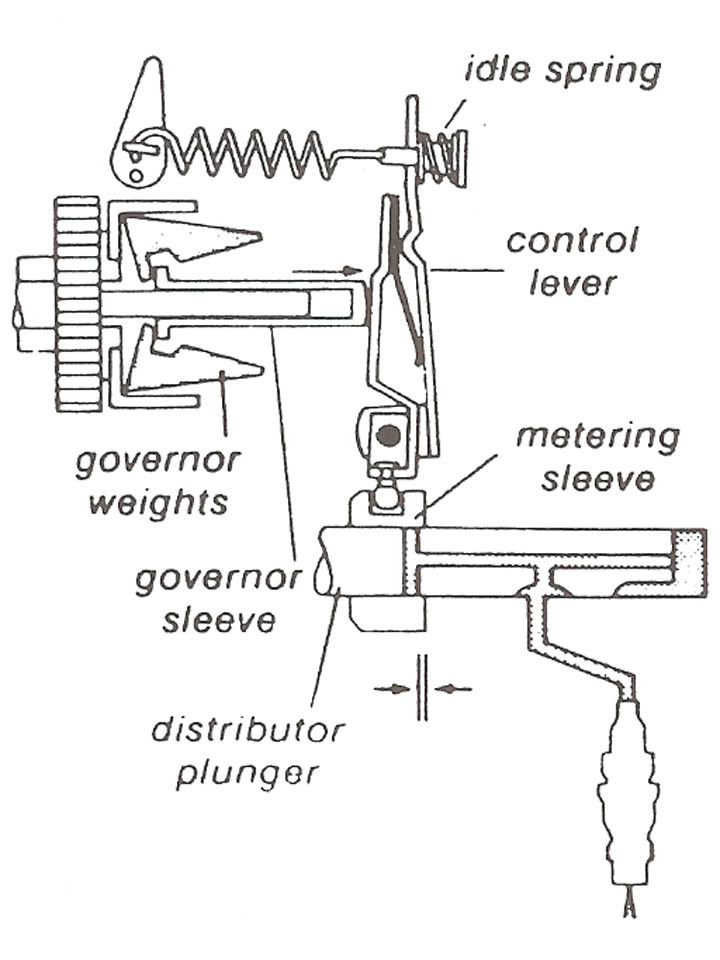

I worked on a friends 92 last weekend and had to pull the pump off because the O ring at the rotor head was leaking. The truck was running fine just leaking fuel badly. So we pulled the pump and pulled the rotor head, replaced the O ring and put everything back together making sure the two springs in the gov section sat in there pockets and the other two smaller springs stayd in there's. Put everything back together and the truck won't start. We cracked the lines and it's not shooting the fuel as it should. The fuel just dribbled out. I took the lines all the way off on the injector side and when you crank it the fuel just dribbles. It has good lift pump pressure, it's in time, rueled out the sthi off solenoid (took the plunger out) re indexed the gov spring. It has me stumped. I'm not familiar with the inner workings of the vane pump and rotor head. Are next step is to take the pump to an Injection shop and have them run it on there stand to find out what's wrong. Just figured I'd ask the VEinds here before going to that step