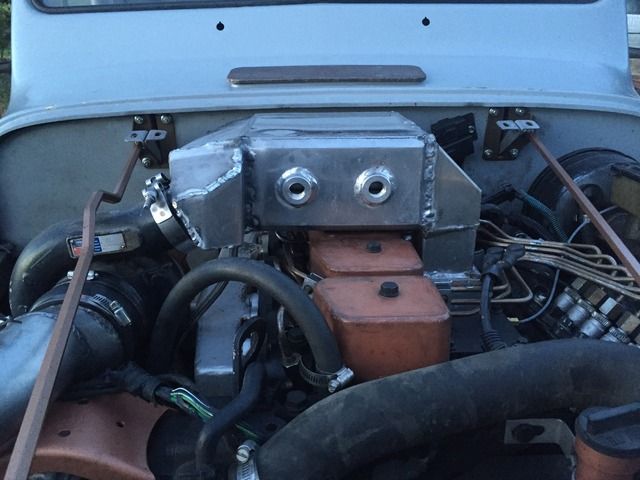

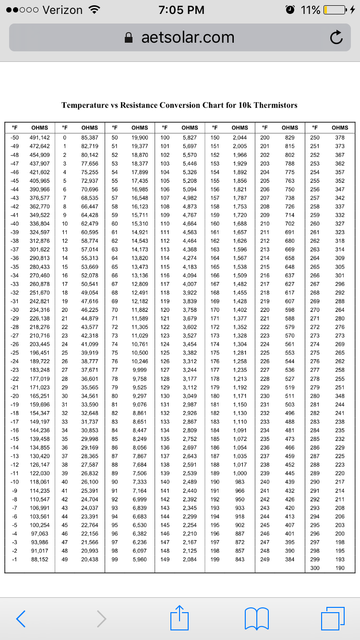

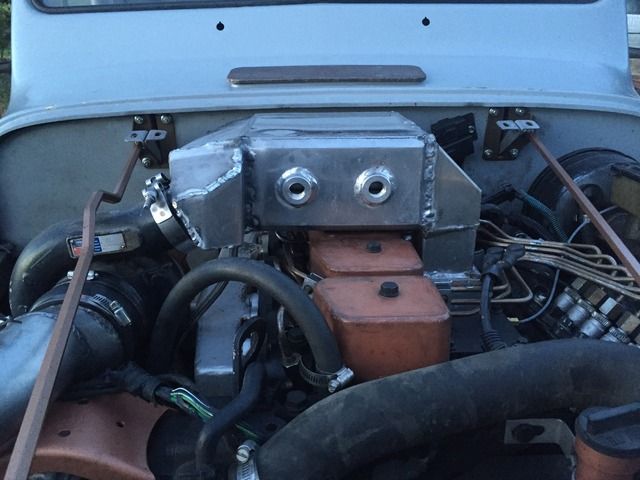

So I still haven't ordered a datalogging setup yet but today before I left for work I attempted to get a little creative. I used the stock charge air temp sensor in the manifold and hooked up a multimeter to the corresponding black/red black/blue wires at the PCM and read resistance. According to a 10k thermister chart, below are my findings.

It was 72* ambient out when I left this morning. Thermistor showed 75* as I sat there and let it idle for warmup. I have the water pump running and the Volvo fan on high speed.

Cruising down the road it sat in the low 90s until my first pull from a stop sign. First pull I hit around 40psi using a little less than half throttle, letting off when I shifted to 3rd. Hit 115 to 120*. Back to cruising and it immediately dropped back to about 95*. A couple more of those pulls through some back roads with a few minutes of 40mph cruising in between. Same results.

Did a decent pull through 3rd gear from a stop sign turning on to the highway. hit about 60psi. Temp got to about 130-135*. Went almost immediately back down to just below 100* as I cruised in 4th, 1400rpm, and 10psi of boost. Got to a decent 1-1/2 mile long grade, shifted to third, powered up the grade hitting about 85mph and 70psi at times. Most of the time I was between 50 and 60psi. Temps at the most got up to 145*. Pretty much coasting down the other side, temps dropped to around 110* immediately and then by the bottom of the grade (about 1 mile or less) got down right below 100*. Back to cruising at 10psi for the remainder of my trip and temps idled around 95-100*.

Needless to say, so far I am extremely happy with the setup. Not ever being able to compare to an air/air; I don't know if my results are anything to brag about, but it is definitely running a lot better than no intercooler at all!

[/URL]

[/URL] [/URL]

[/URL]