Regarding manifold usage / application:

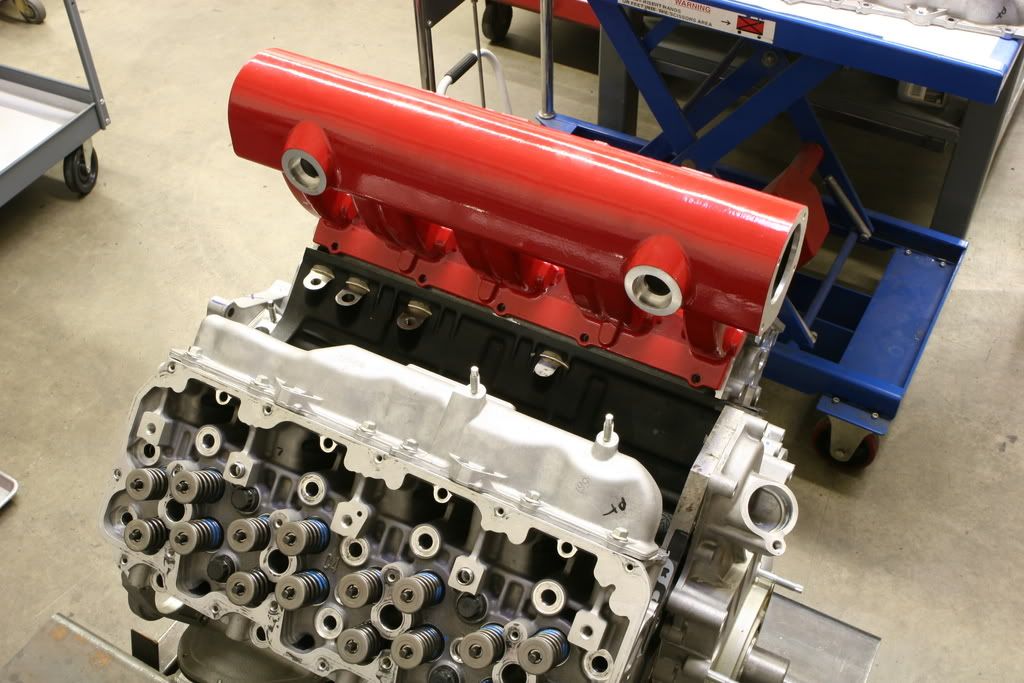

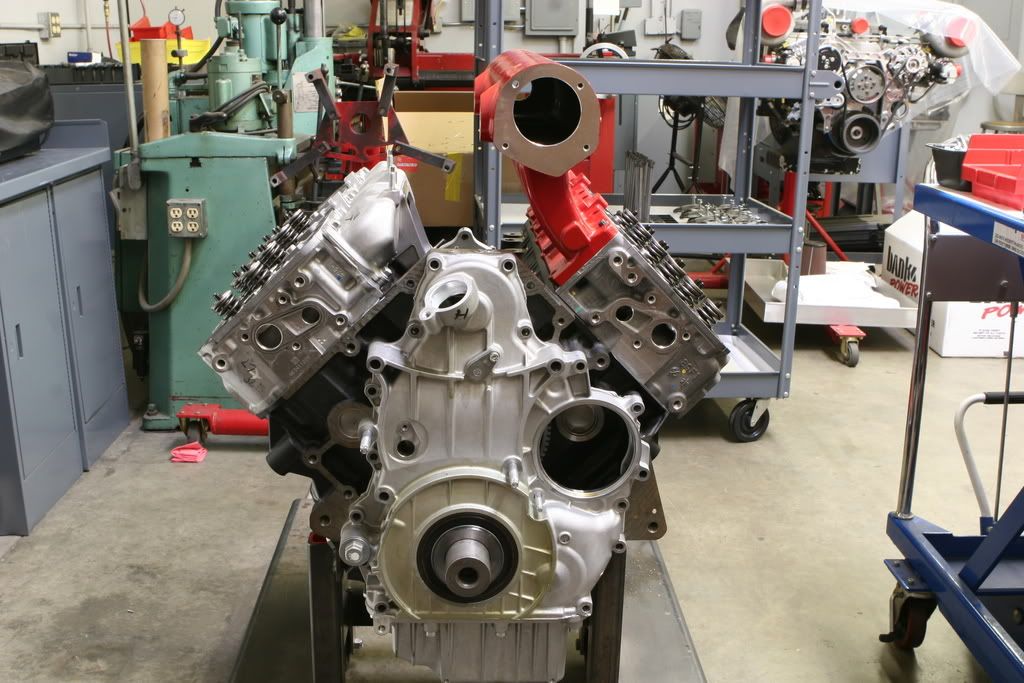

- No loss of low-speed engine efficiency. We currently have several different engine builds using these manifolds, and all show improved VE vs stock, even at our lowest 1500 RPM test point. Functional runner length actually increases vs. the stock clamshells, and you eliminate a pair of zero-radius short-side turns.

- As Jeff said before, the runner length can't be specifically 'tuned' for a specific RPM range because of the difference in effective port length inside the cylinder head. Again, based on cam selection, I've seen VE peaks with these manifolds range from low-2000 RPM (stock cam / heads) to high 4000 RPM (moderate-aggressive race cam / ported heads). With their good plenum volume, runner size and taper, the manifolds still work well up to and over 5500 RPM.

- CP3's: Nothing radical. They are currently turning at engine speed (this may change in the future) - as we've said before, the only thing you have to do is ensure that the inner chamber pressure remains adequate. You can monitor this by drilling and tapping the housing and fitting a pressure sensor. We use a boost-referenced fuel pressure regulator to increase feed pressure to the pumps under boost to maintain adequate chamber pressure.

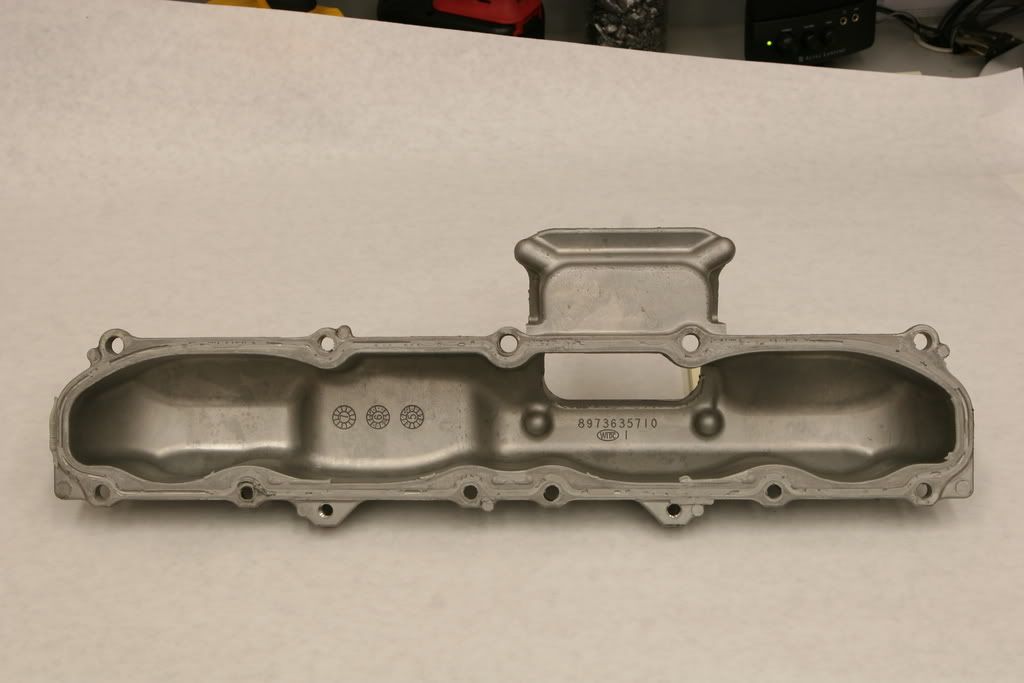

- Usability: This setup lets you keep the stock gear driven fuel pump, rails, lines (one substitution, the crossover line, which comes with the kit), etc. You do have to find a different spot to put the turbo, however.

Hope that answers everyone's questions - fire off any more you've got.