It keeps me from pegging my pyro. Now I only spend around 10 seconds at 1450 degrees on the quarter mile, but no pegging...

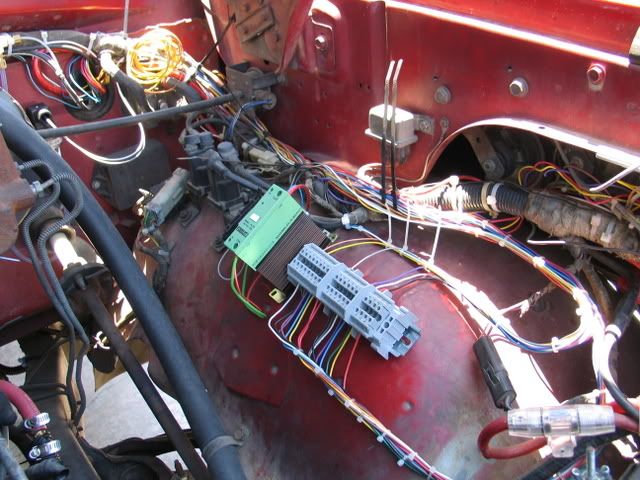

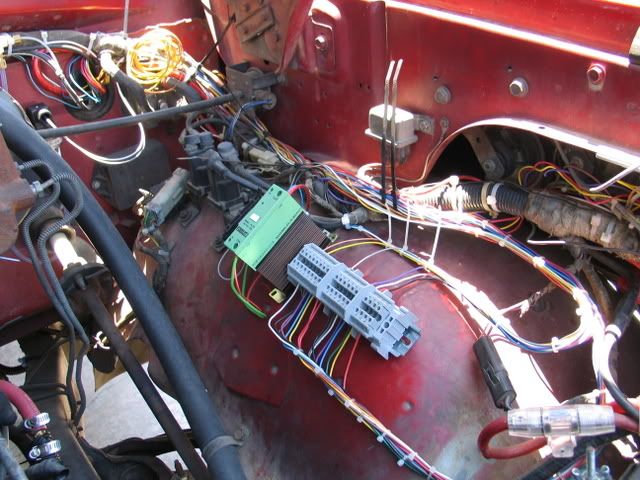

I was programming it for 7 stages yesterday instead of 3, and my box died. Cooling Mist says I need to reflash it... That's the most recent thing that's happened.

Cooling Mist has EXCELLENT customer support, by the way. Last few emails I've sent them have been responded to in less than an hour.

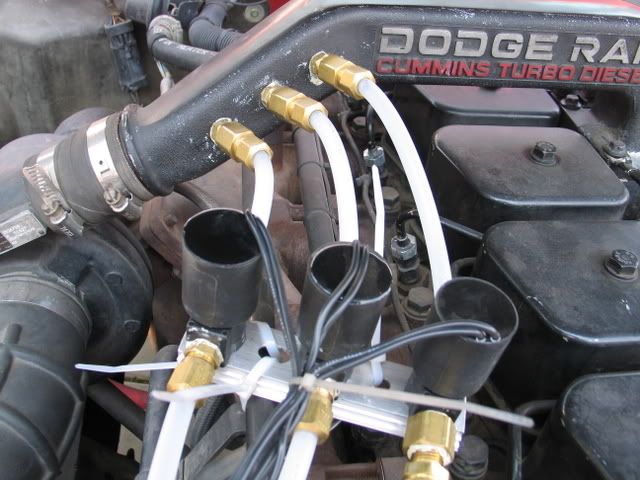

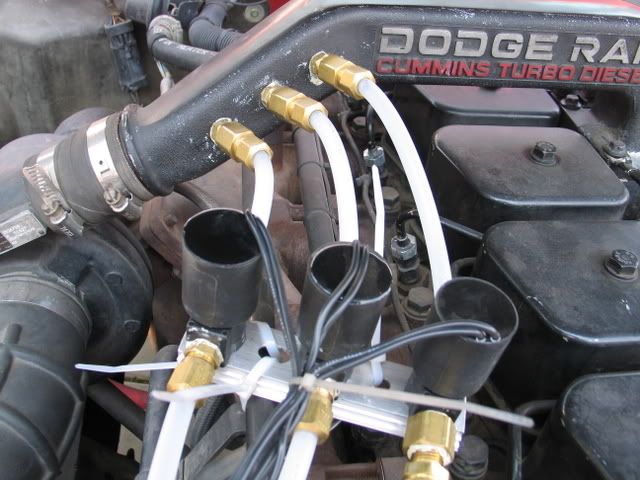

Next step is 1000 PSI... I can't decide whether to use an off-the-shelf 120 volt model from eBay along with a big inverter, or to put a starter motor on a CraigsList washer pump. Whatever route I go, I'm going to need to use a couple nitrous solenoids... That'd give me three stages for the 1000 PSI water, then I use the finer control of the 150 PSI system for methanol mix.

But before I play with more water, I need something like an intake or exhaust or injectors or something.