-Boostjunky-

Boost-A-Holic

- Joined

- Apr 26, 2009

- Messages

- 132

OK, so, I know a lot of us are already aware that the aftermarket ratings of injectors are not very representative of what's actually being injected in terms of real world use. I learned this fact some years ago, and it has bothered me ever since to see people tossing around flow ratings in the 30, 40, and 50 LPM range.

I mean, let's be realistic, here. If you had injectors that injected such large quantities of fuel, you'd probably hydro-lock your motor with fuel.

More realistic figures have been claimed to be in the 1 LPM range for stock HPCR Cummins injectors, and with using 100% over injector nozzles, more like 2 LPM. That seems much more realistic, and thanks to honest companies like Exergy, we have flow data to back those figures up.

I just recently had a friend get his Duramax injectors flow tested at a local Diesel repair and performance shop (Gillette Diesel), and he came back with flow figures in the 31 LPM range, and that they were 55% over stock. He was not given a flow sheet, they didn't tell him any specifics as to balance percentages or backflow values, they just told him, "Everything looked good."

This bothers me. BADLY. No substantial data was given to back up their claim of "Everything looked good." And the fact that they rated the injectors at 31 LPM just bothered me even more.

So, I wanted to know if anyone out there has any idea how these shops are coming up with these flow ratings. I've heard that some shops test injectors with compressed air, and that this is how they come up with flow ratings in the 30+ LPM range. I asked my friend to verify that Gillette wasn't using air in their testing procedure, and they assured him that they did, in fact, use a liquid (what liquid, I don't know), and that they have a "fancy" common rail injector test stand.

How, then, are they coming up with 31 LPM? I just don't understand.

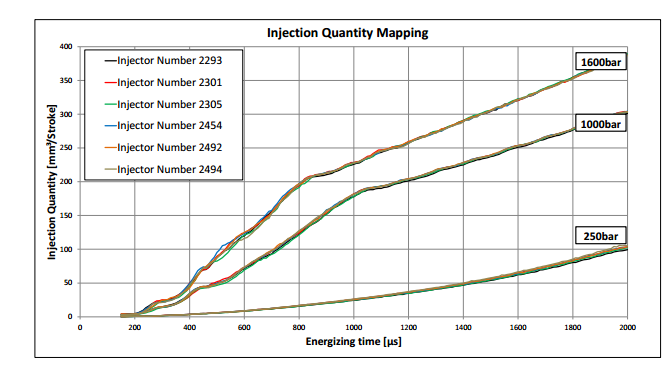

Furthermore, how does one take the data from an Exergy printout, where it shows injected quantity in mm3 at different pressure ranges and pulsewidth values, and translate it to a LPM rating?

I know that Exergy ends up usually printing out the LPM rating on the sheet, but I have seen a sheet (which I will attach) for stock injectors that only showed the mm3 values, and didn't show what the LPM rating was for said injectors.

If anybody has a formula to take the mm3 ratings to translate them into a LPM figure, that would be awesome. I suppose it would help to know what the mm3 rating was derived from in terms of how many times the injector was fired for the test, given the pressure and pulsewidth at that injector at the time of the test.

On to some data sheets:

Stock nozzles (these are the ones without a LPM rating)

60% over injectors

105% over injectors

Any insight would be greatly appreciated.

I mean, let's be realistic, here. If you had injectors that injected such large quantities of fuel, you'd probably hydro-lock your motor with fuel.

More realistic figures have been claimed to be in the 1 LPM range for stock HPCR Cummins injectors, and with using 100% over injector nozzles, more like 2 LPM. That seems much more realistic, and thanks to honest companies like Exergy, we have flow data to back those figures up.

I just recently had a friend get his Duramax injectors flow tested at a local Diesel repair and performance shop (Gillette Diesel), and he came back with flow figures in the 31 LPM range, and that they were 55% over stock. He was not given a flow sheet, they didn't tell him any specifics as to balance percentages or backflow values, they just told him, "Everything looked good."

This bothers me. BADLY. No substantial data was given to back up their claim of "Everything looked good." And the fact that they rated the injectors at 31 LPM just bothered me even more.

So, I wanted to know if anyone out there has any idea how these shops are coming up with these flow ratings. I've heard that some shops test injectors with compressed air, and that this is how they come up with flow ratings in the 30+ LPM range. I asked my friend to verify that Gillette wasn't using air in their testing procedure, and they assured him that they did, in fact, use a liquid (what liquid, I don't know), and that they have a "fancy" common rail injector test stand.

How, then, are they coming up with 31 LPM? I just don't understand.

Furthermore, how does one take the data from an Exergy printout, where it shows injected quantity in mm3 at different pressure ranges and pulsewidth values, and translate it to a LPM rating?

I know that Exergy ends up usually printing out the LPM rating on the sheet, but I have seen a sheet (which I will attach) for stock injectors that only showed the mm3 values, and didn't show what the LPM rating was for said injectors.

If anybody has a formula to take the mm3 ratings to translate them into a LPM figure, that would be awesome. I suppose it would help to know what the mm3 rating was derived from in terms of how many times the injector was fired for the test, given the pressure and pulsewidth at that injector at the time of the test.

On to some data sheets:

Stock nozzles (these are the ones without a LPM rating)

60% over injectors

105% over injectors

Any insight would be greatly appreciated.

Last edited: