cummins2001

New member

- Joined

- Oct 15, 2008

- Messages

- 31

We'll, I got my swap all finished up, I've been runing it for about a month now and everythings going great ! all though its runing great, its not done, (but is it ever ?) I am waiting on mach 4's and some other odds and ends. Hope you like the pics. and hope it helps some one else out ! Also, I plan to dyno at diesel days in Dillsburg this spring, so all I can really say is going by the seat its more then my VP set up that was at 375hp and 896ft lbs, thanks for looking -Ethan

A dead doge.

A dead doge.

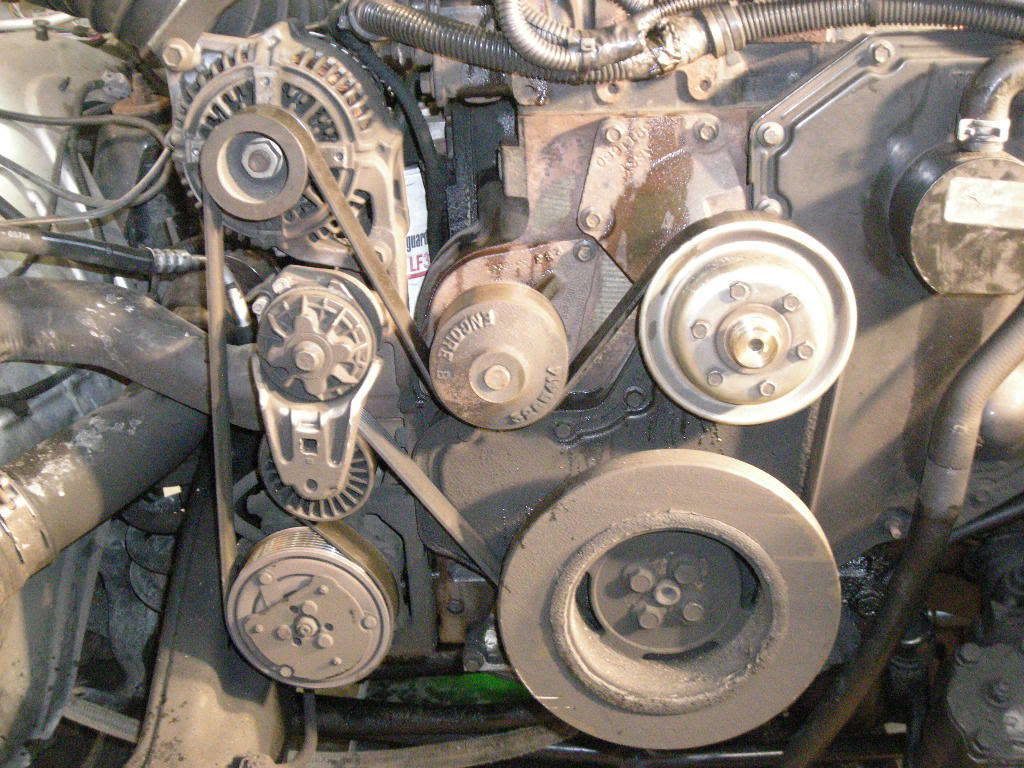

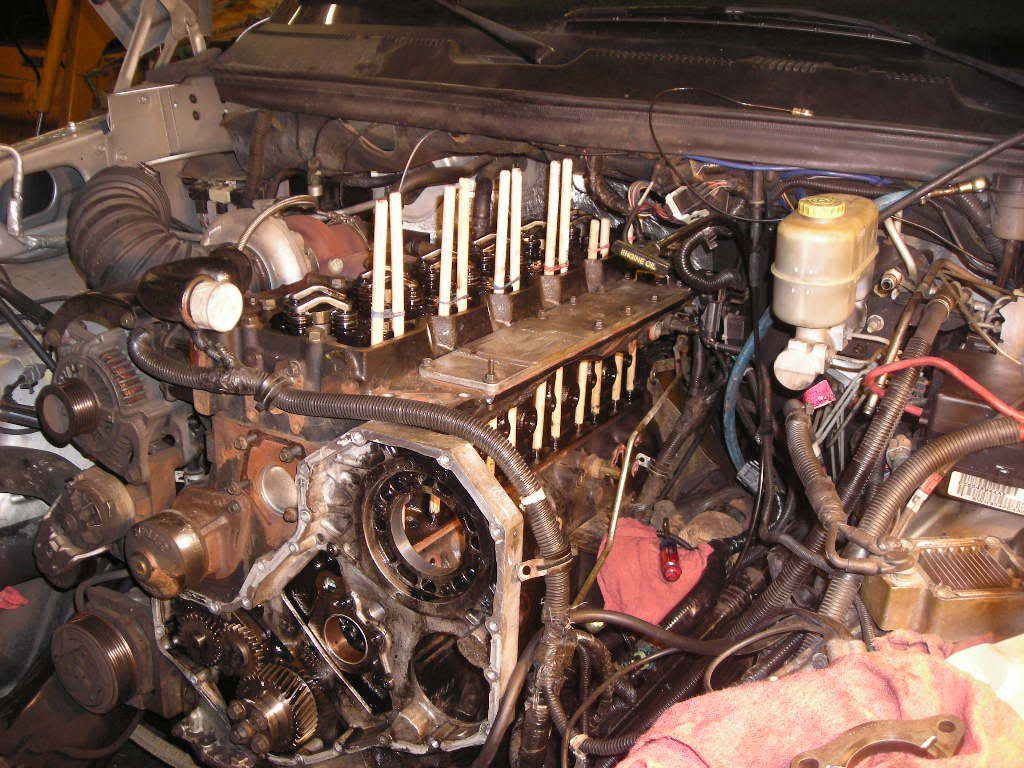

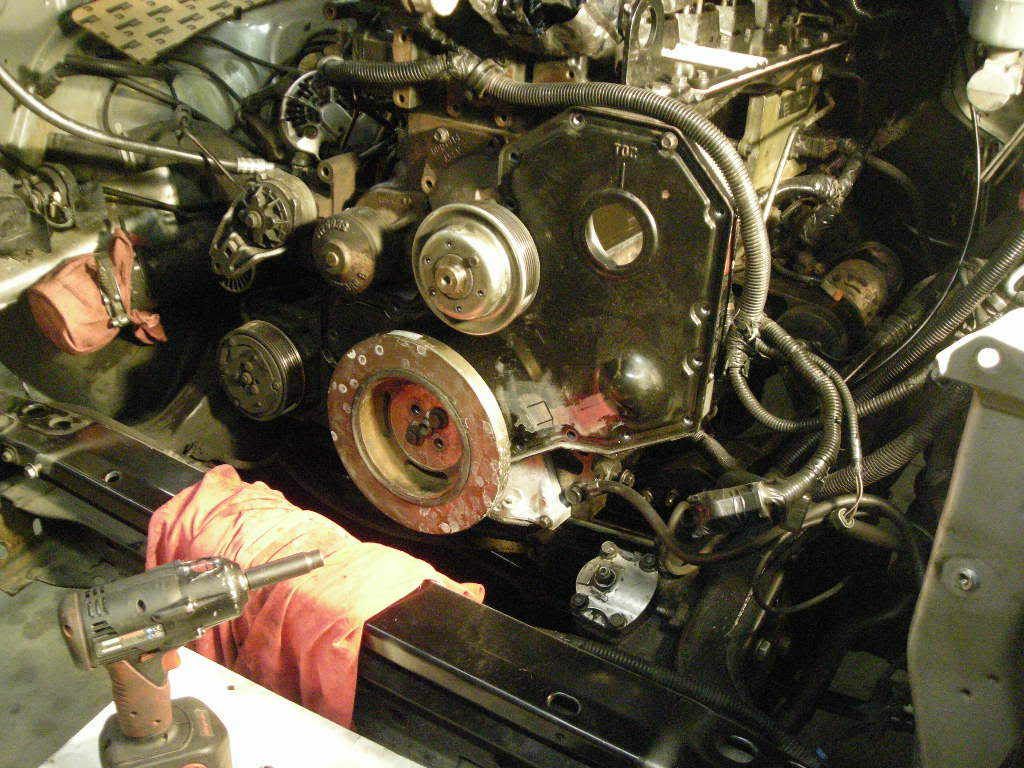

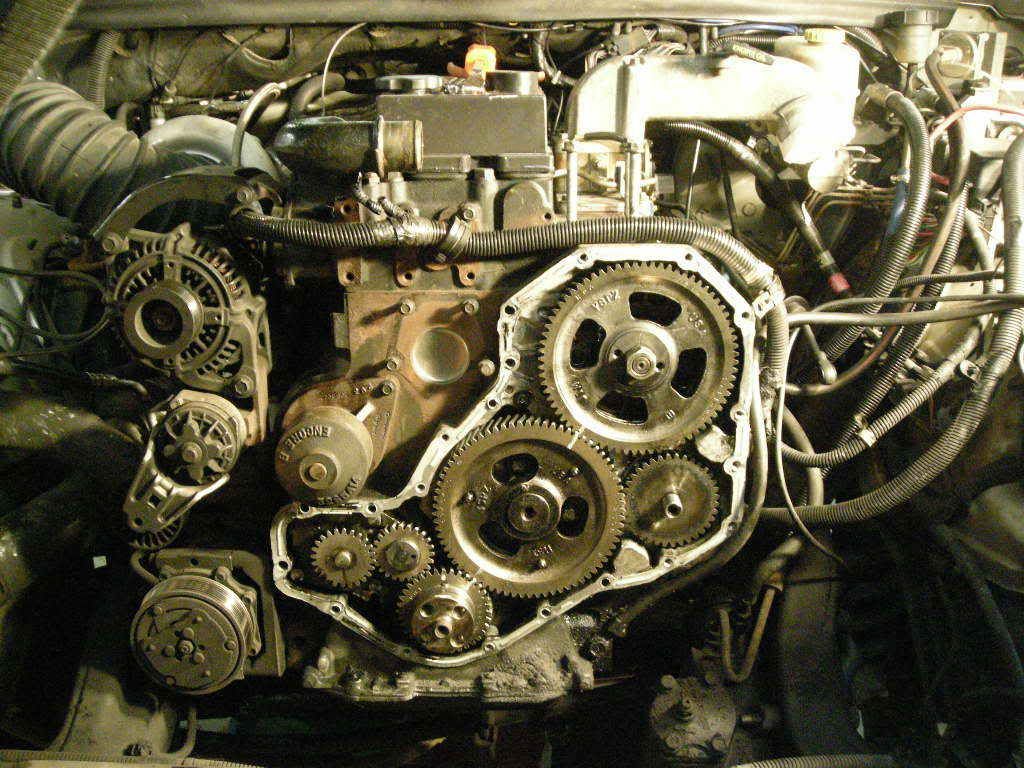

coming apart.

coming apart.

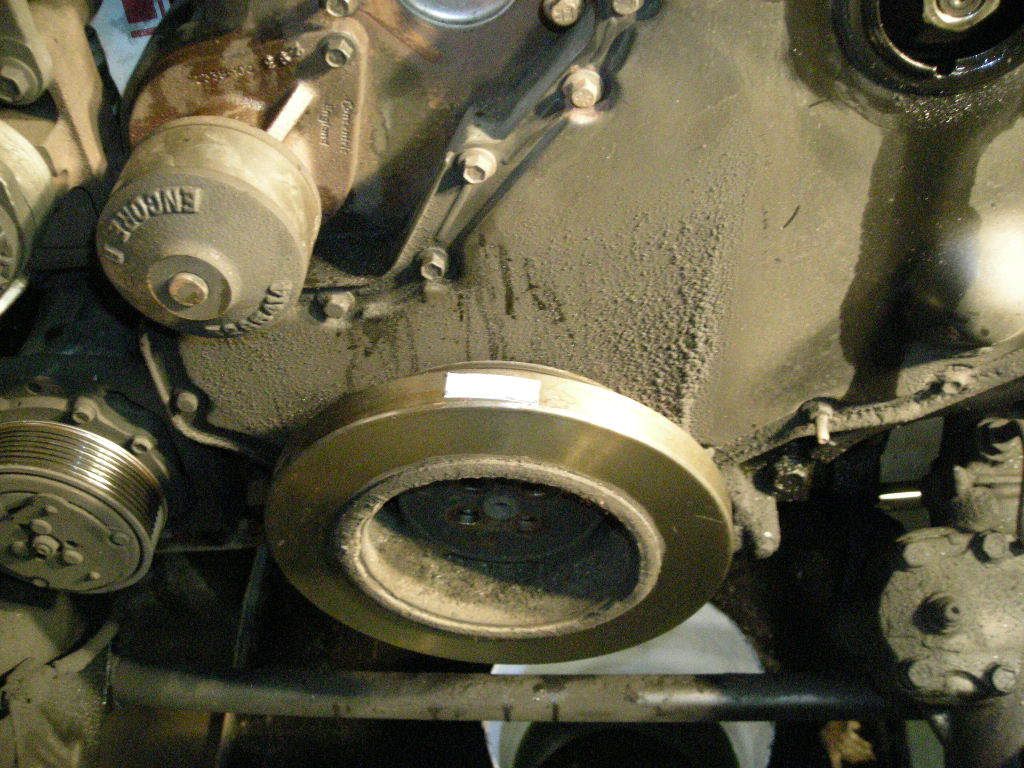

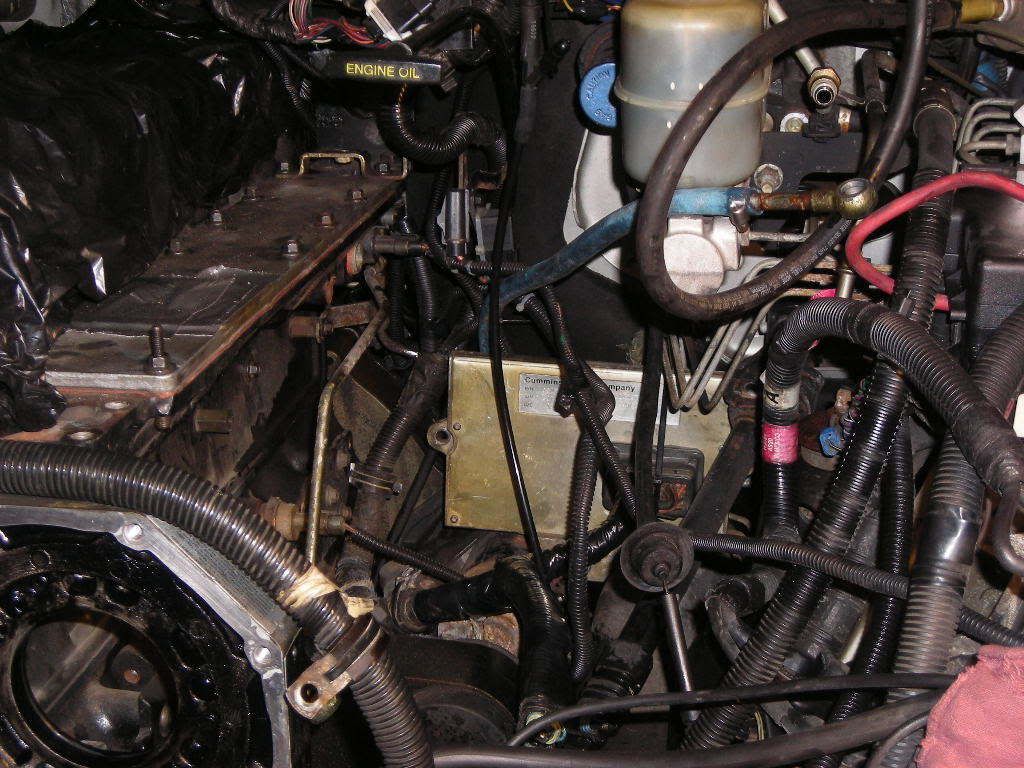

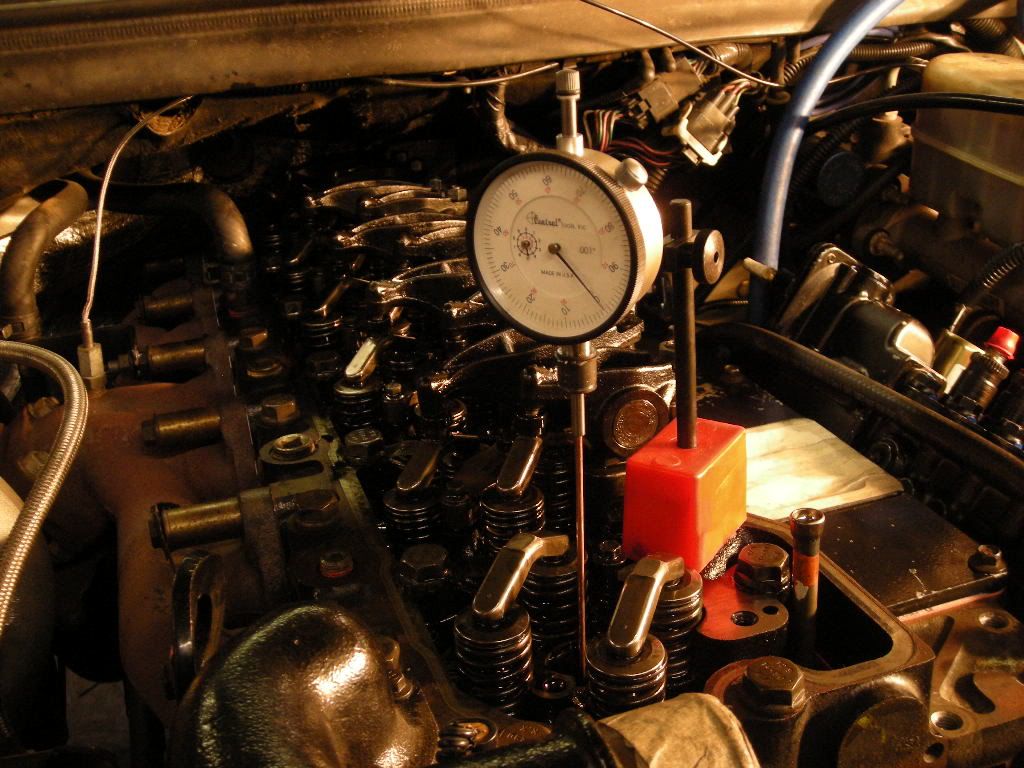

the issue.

the issue.

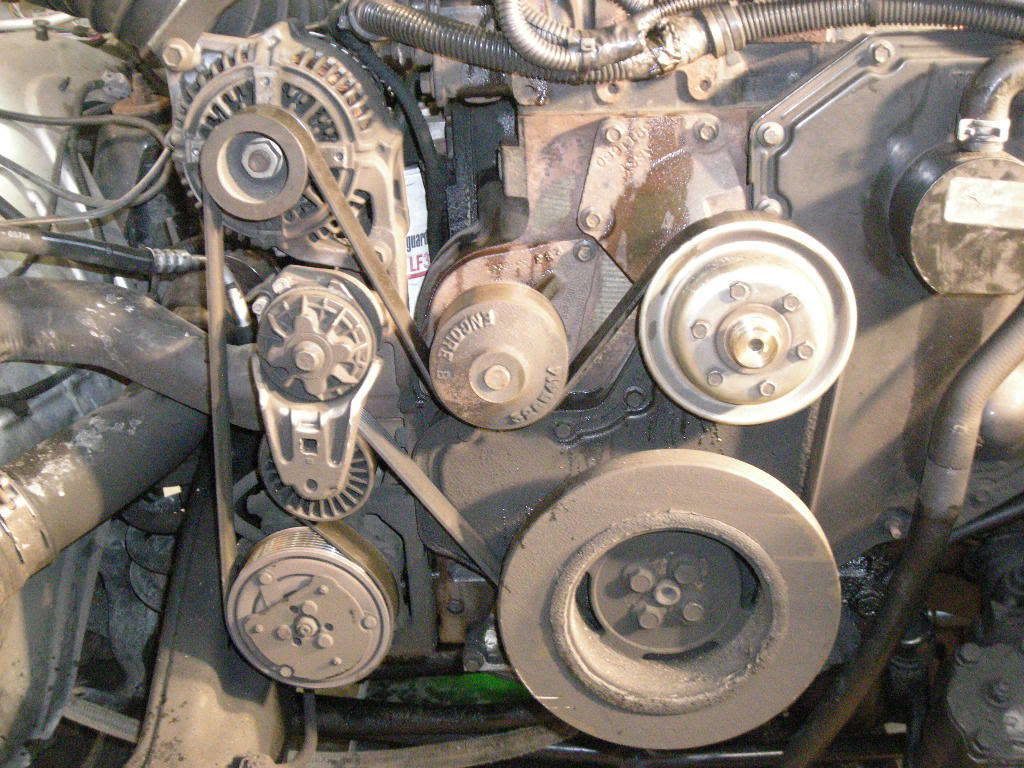

Strap the condensor out of the way.

Strap the condensor out of the way.

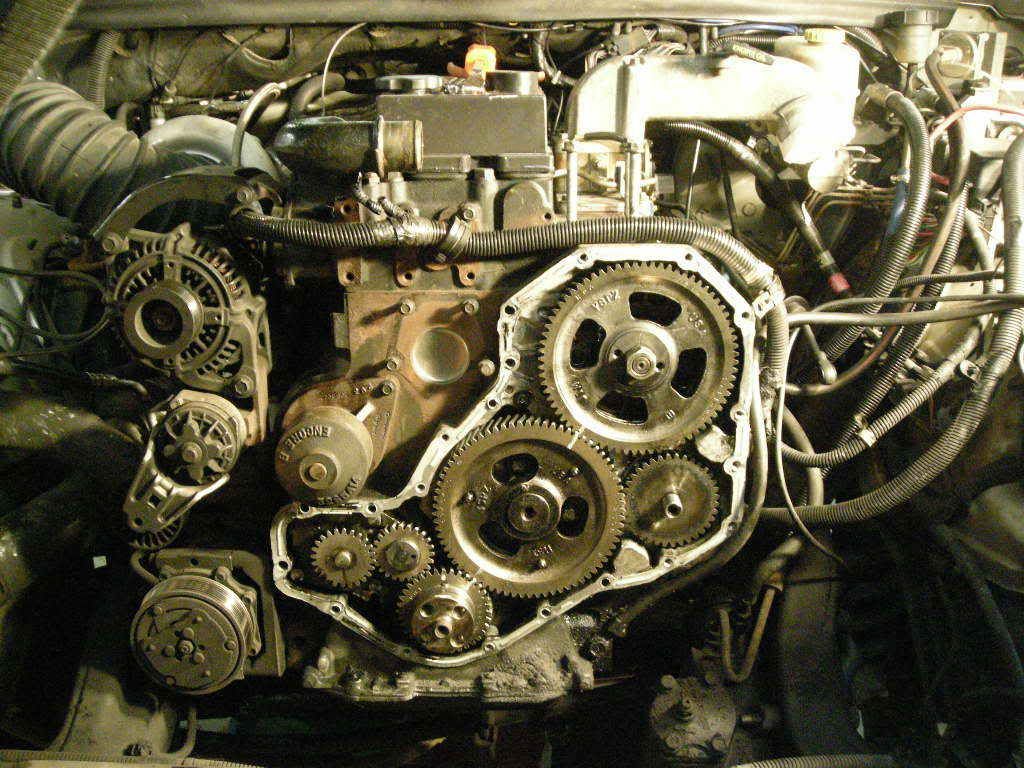

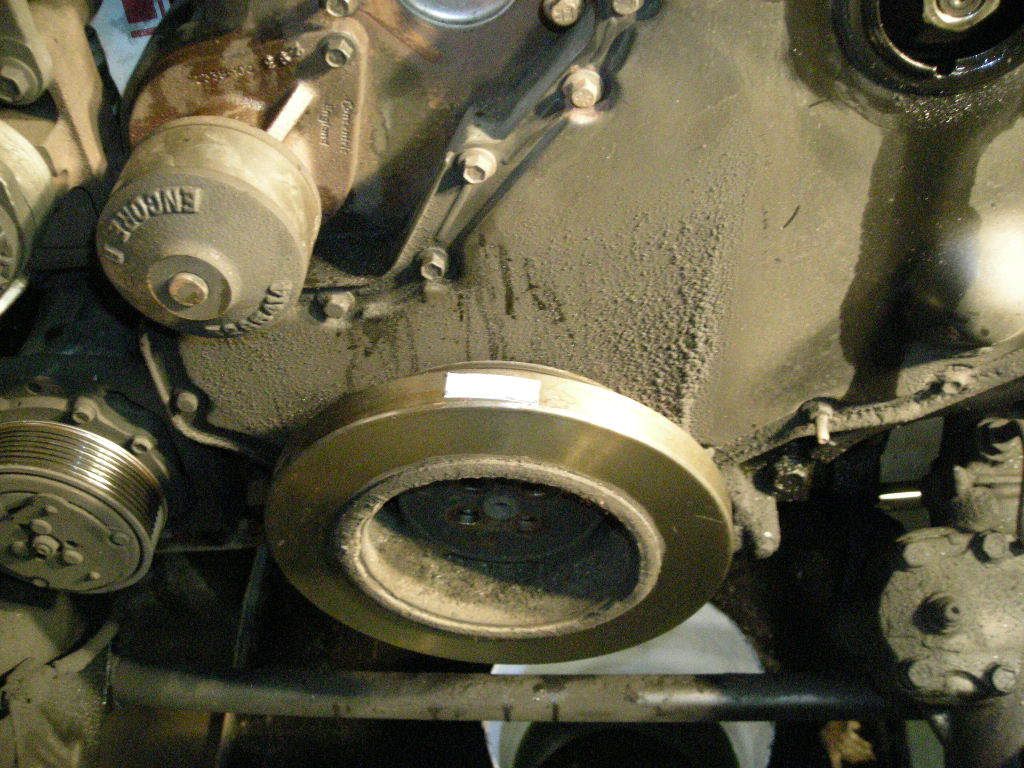

KDP. looked to be holding strong.

KDP. looked to be holding strong.

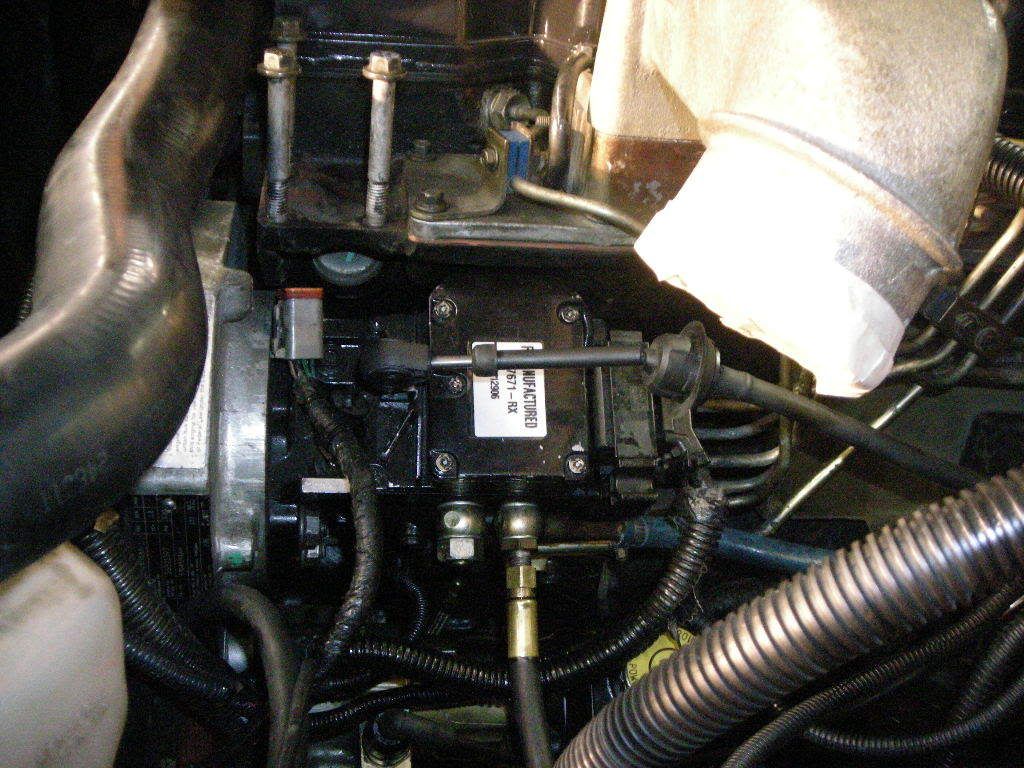

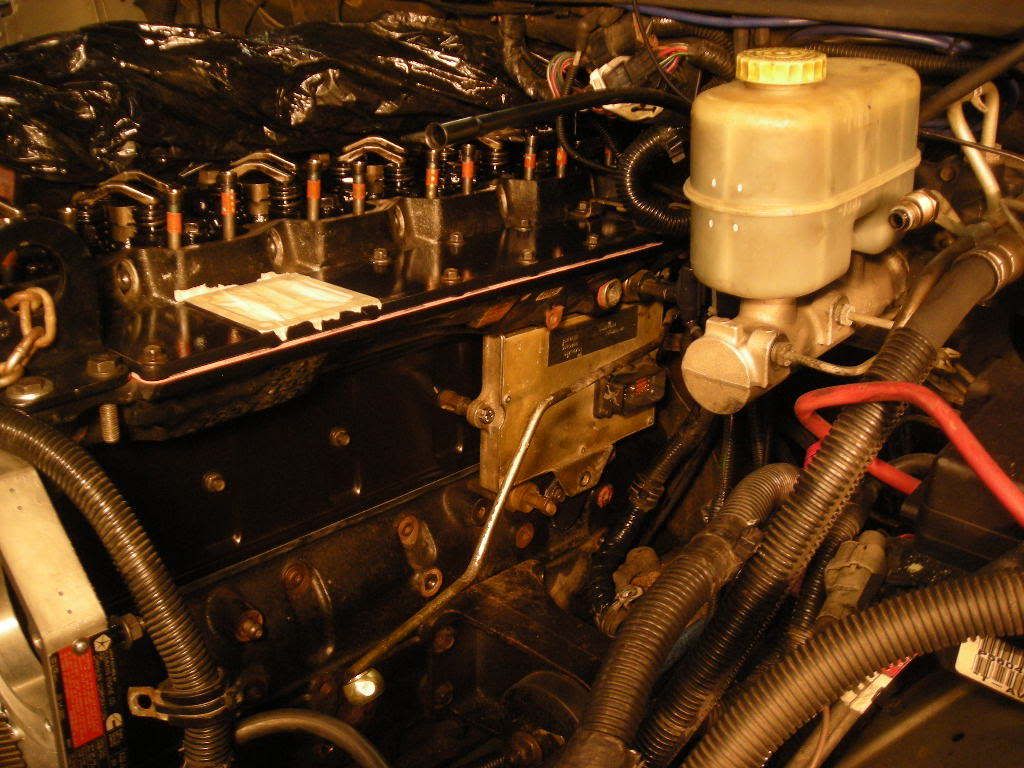

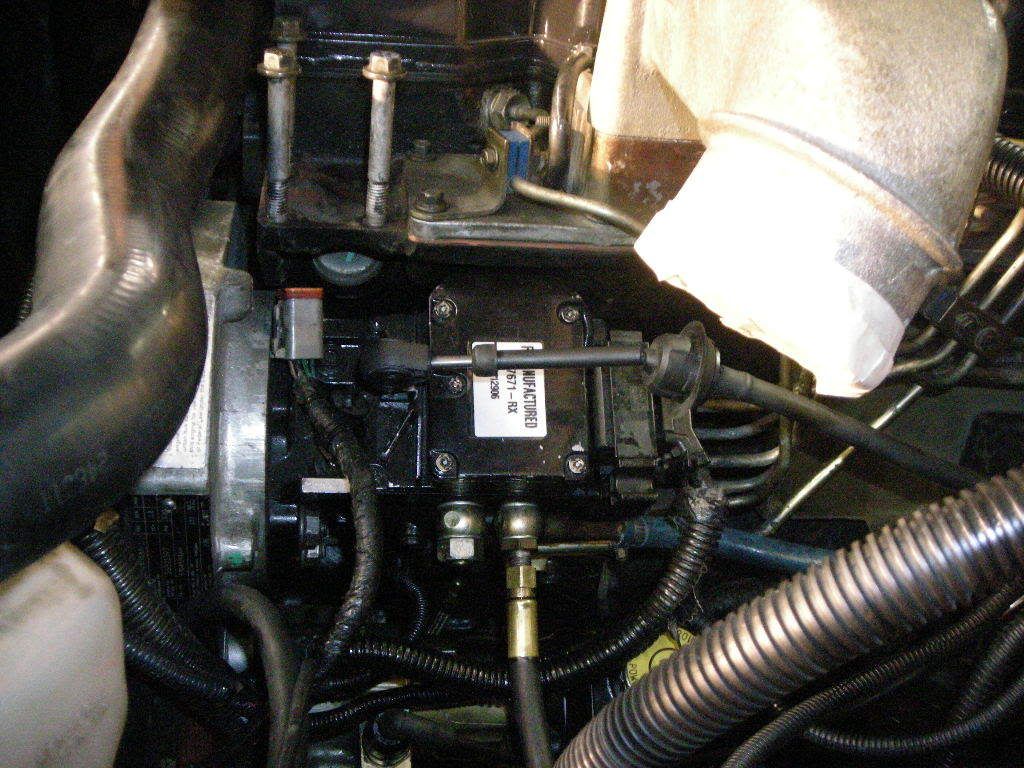

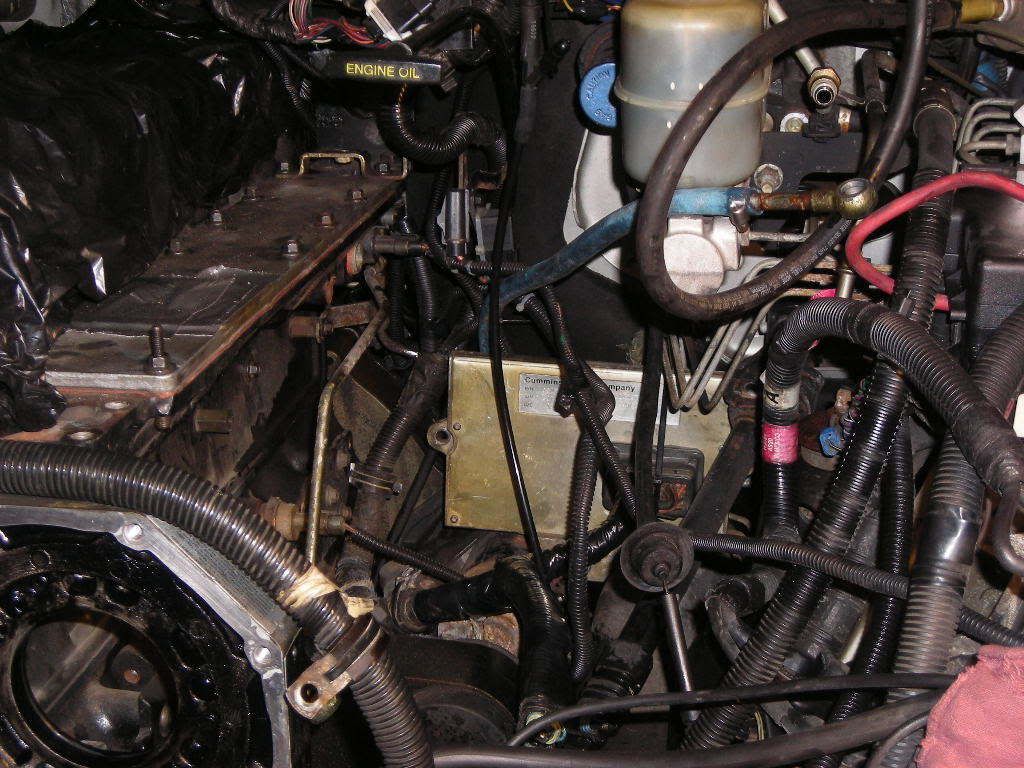

where to stuff the ECM...

where to stuff the ECM...

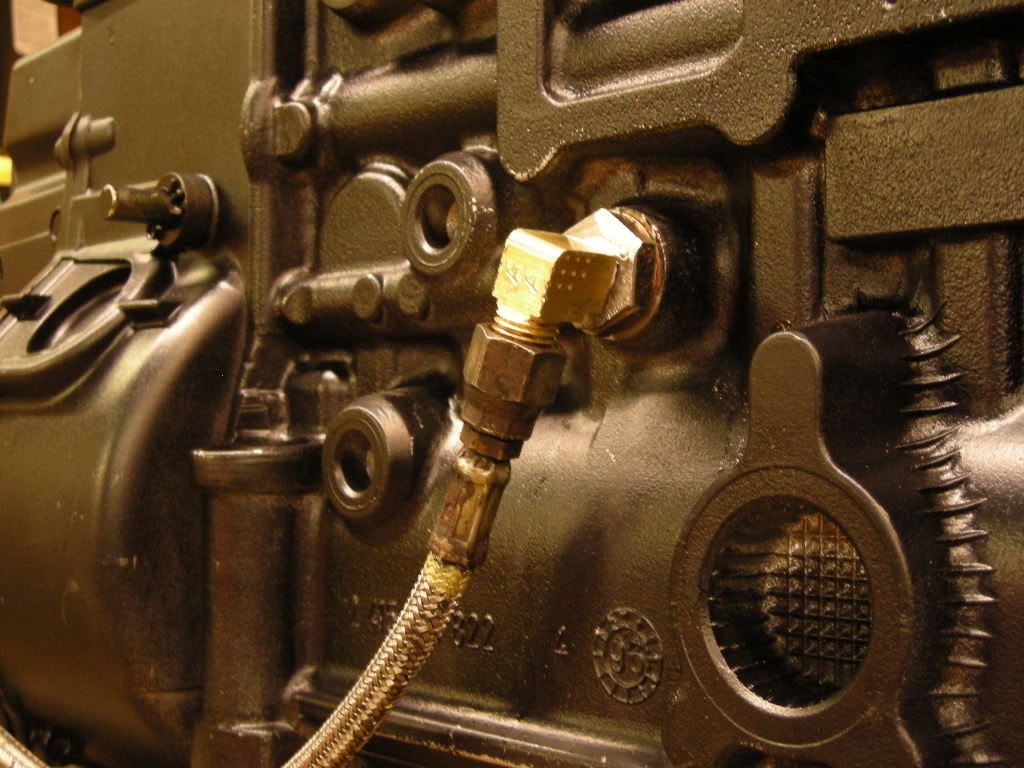

Notice how i notched the bracket on the bottem of the ECM, this is to clear my mechanical lp block off plate.

Notice how i notched the bracket on the bottem of the ECM, this is to clear my mechanical lp block off plate.

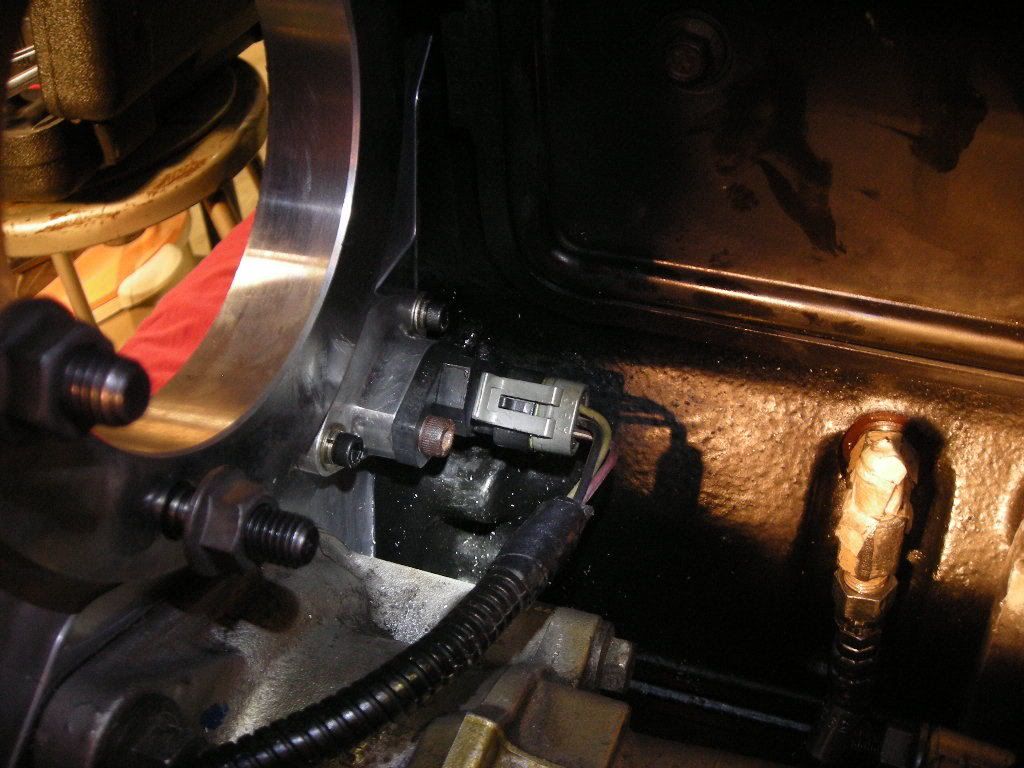

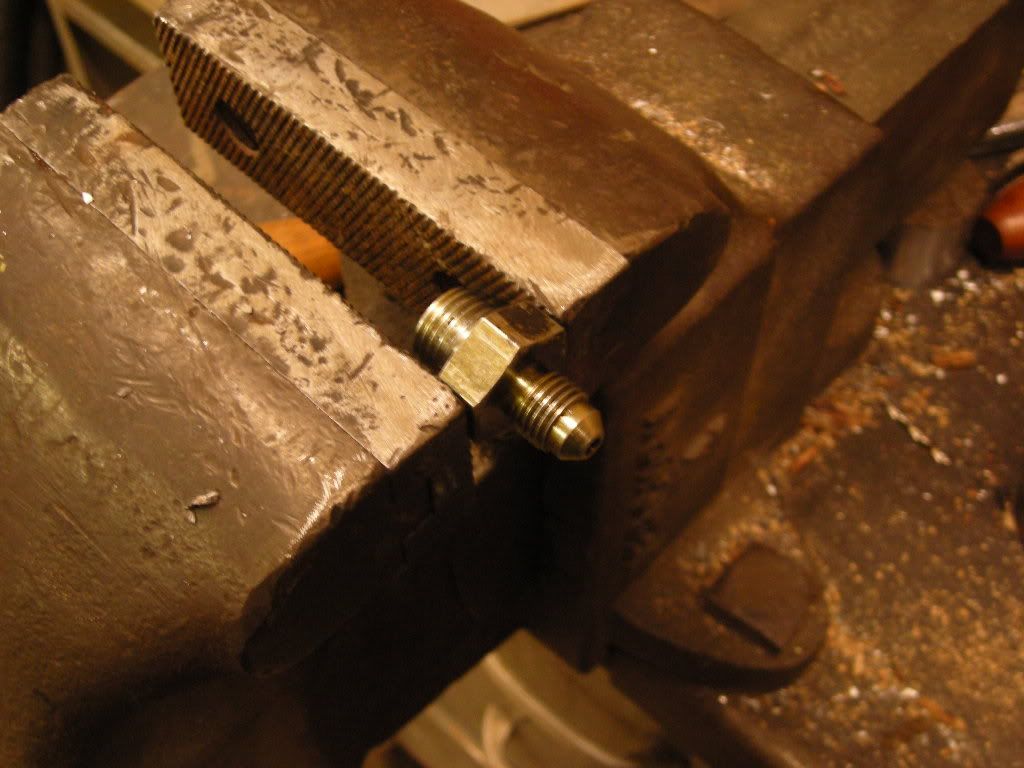

I made this block off plate, they can be bought however....

I made this block off plate, they can be bought however....