SledPuller21

Never enough

- Joined

- Jan 18, 2007

- Messages

- 2,214

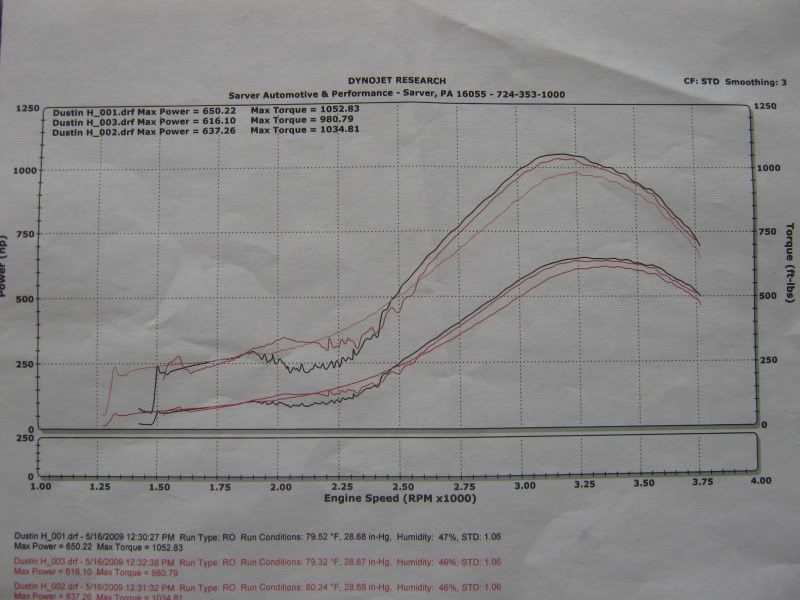

Just got in from sarver and put out 650hp and 1052tq. I felt from driving my truck and riding in other CRs I've worked on that I should've been well into the low 700's. My question is why so low on the tq? I dynoed last year and got 572hp and 1162tq with a different setup and the stock charger. Also I was told by the operator to run my truck in 6th (5 other times I've dynoed other places they go with 1:1 in 5th). Anyhow went God knows how fast and only saw 1250 egt(I hit 1800 WOT by 3700 in 6th on the street)... didnt get a boost reading since I blew my line off the gauge on the way there. I know I have enough fuel to heat a large house, and a enough air to support 700...what gives? Any thoughts or just not enough load on the dyno? I'll get my sheet up when I can and hopefully someone from sarver got a vid of my run. Thanks.