seeker1056

gear head

- Joined

- Aug 3, 2006

- Messages

- 1,001

Ok so I bottom tapped all of the holes in the block - gained 1 thread only

time to install studs into the head - installed all of them till just barely touching the bottom of the holes

installed the head

lo and behold all of the short exhaust side studs only show like three threads out of the head , put the washer on and no threads showing - so obviously the nut aint goin on

middle studs show enough thread for both washer and nut

long rocker studs have enough thread to allow just the nut to go on and show one thread - if i back the rocker studs out to allow a washer, then they hit the valve covers

short studs needed to be backed out 6 threads to allow both a washer and a nut and have stud just flush with the top of the nut - and looking at the stud there is only like 8 threads on it and looking into the block hole, there is a 1/8" recess before the threads even start

so how much thread needs to be engaged into the block and be safe?

I have run into many wierd things with my VE 12v - so is this another one? different thread depths etc

can I run the short and long studs without washers if I use lots of moly and a smooth torque sequence

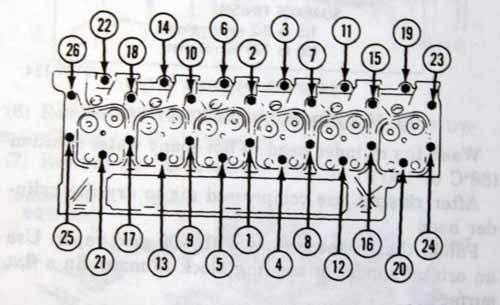

also cant seem to find the correct bolt tightening sequence - so is it very specific or do I just work my way out clockwise from the centre bolts/studs like i would any other motor

suggestions - help???

thanx

Ken

time to install studs into the head - installed all of them till just barely touching the bottom of the holes

installed the head

lo and behold all of the short exhaust side studs only show like three threads out of the head , put the washer on and no threads showing - so obviously the nut aint goin on

middle studs show enough thread for both washer and nut

long rocker studs have enough thread to allow just the nut to go on and show one thread - if i back the rocker studs out to allow a washer, then they hit the valve covers

short studs needed to be backed out 6 threads to allow both a washer and a nut and have stud just flush with the top of the nut - and looking at the stud there is only like 8 threads on it and looking into the block hole, there is a 1/8" recess before the threads even start

so how much thread needs to be engaged into the block and be safe?

I have run into many wierd things with my VE 12v - so is this another one? different thread depths etc

can I run the short and long studs without washers if I use lots of moly and a smooth torque sequence

also cant seem to find the correct bolt tightening sequence - so is it very specific or do I just work my way out clockwise from the centre bolts/studs like i would any other motor

suggestions - help???

thanx

Ken

Last edited: