GOT-Torque

is

- Joined

- Jul 2, 2007

- Messages

- 5,284

Anyone seen this done or tried it?

My shafts are worn and so are my rocker arms. I hate to spend the money to buy new stock parts and still have the stock setup, so why not have my rocker arms machined to accept roller bearings and just put new rocker shafts in...

I thought someone had some for sale in the classifieds a while ago (that a shop did) but before I could get any info from him they were sold...

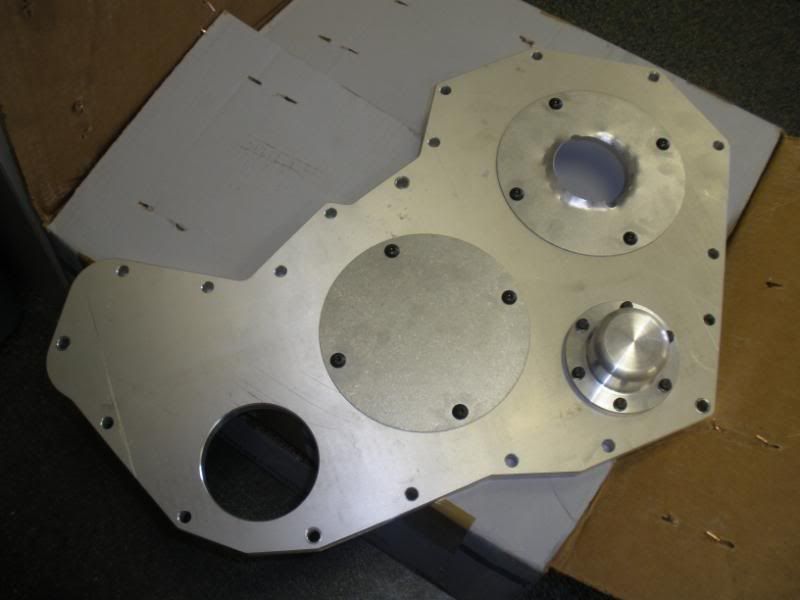

I'm talking about installing a roller bearing into the rocker arm like in the picture below...

My shafts are worn and so are my rocker arms. I hate to spend the money to buy new stock parts and still have the stock setup, so why not have my rocker arms machined to accept roller bearings and just put new rocker shafts in...

I thought someone had some for sale in the classifieds a while ago (that a shop did) but before I could get any info from him they were sold...

I'm talking about installing a roller bearing into the rocker arm like in the picture below...