Got around to finally doing a full manual valve body in my Suncoast 48re. Here are a few tips for those who plan to go at this in the future with some of the questions i had along the way.

Heres what i used:

-Trans Go TFOD-3 manual valve body kit

-a 46re valve body, yes a 46re will also work just fine

-Turbo Action SCS Cheetah shifter

-some misc electrical connectors and wires

-sockets, screw drivers, a bench top grinder, drill

MAKE SURE TO BLOCK THE TRUCK SO IT WONT ROLL, YOU WILL BE UNHOOKING THE PARKING ROD IN THE TRANSMISSION!!!!!!!

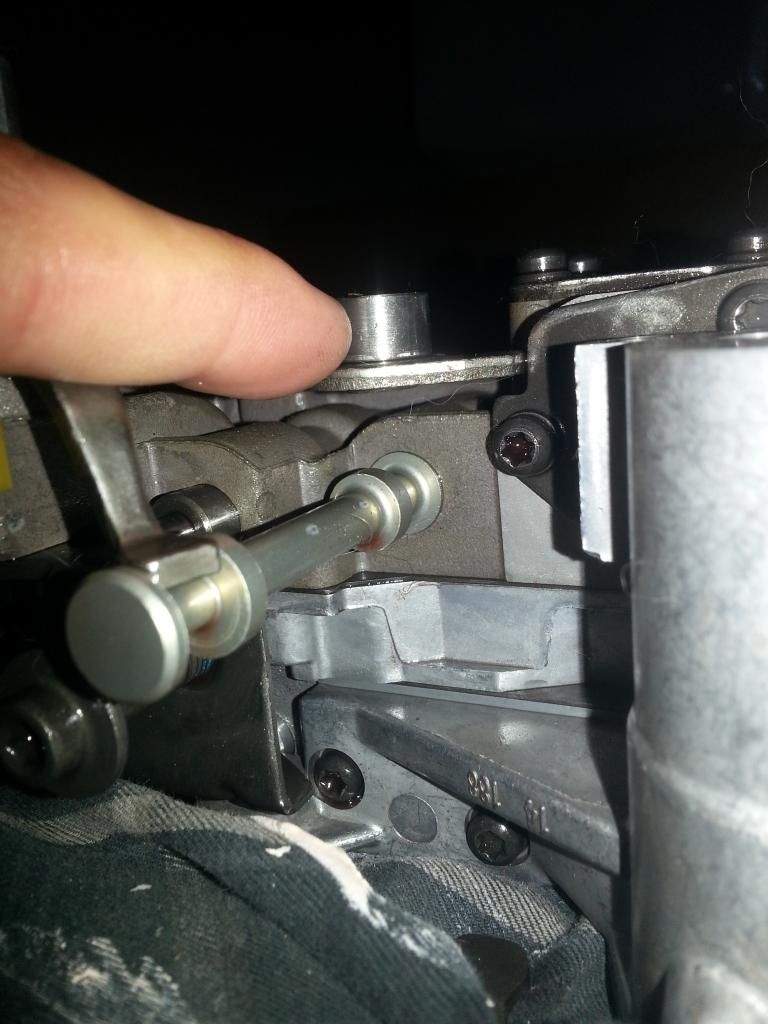

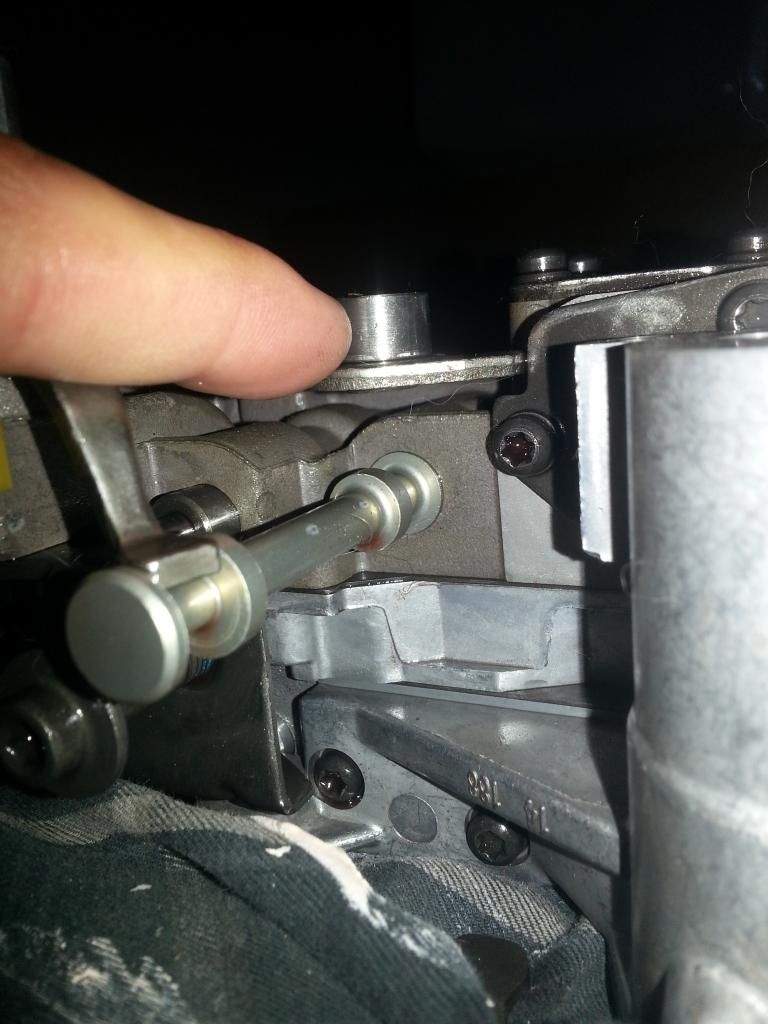

Removing the valve body is straight forward, remove shifter linkage and tv motor or cable, drain the oil, remove the pan and filter, remove all the 11mm valve body bolts except for one or two to hold it up while you remove the parking rod c clip. C clip is located on the underside of where my finger tip is, use a long flat head screwdriver to pop it off then pull the valve body out

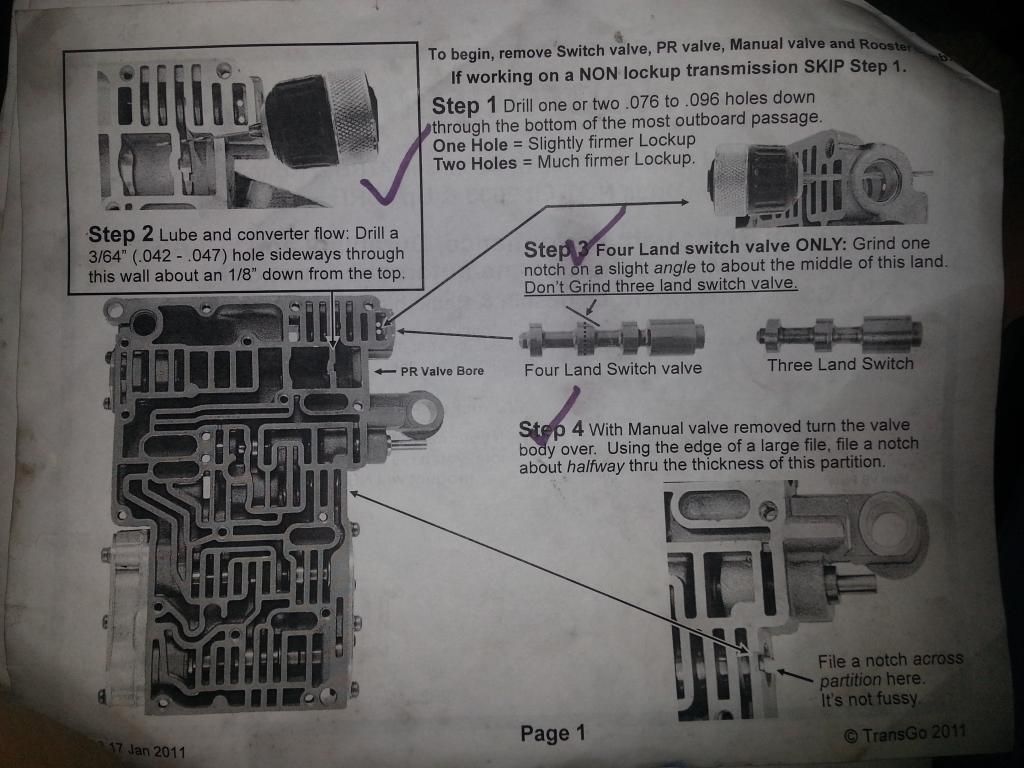

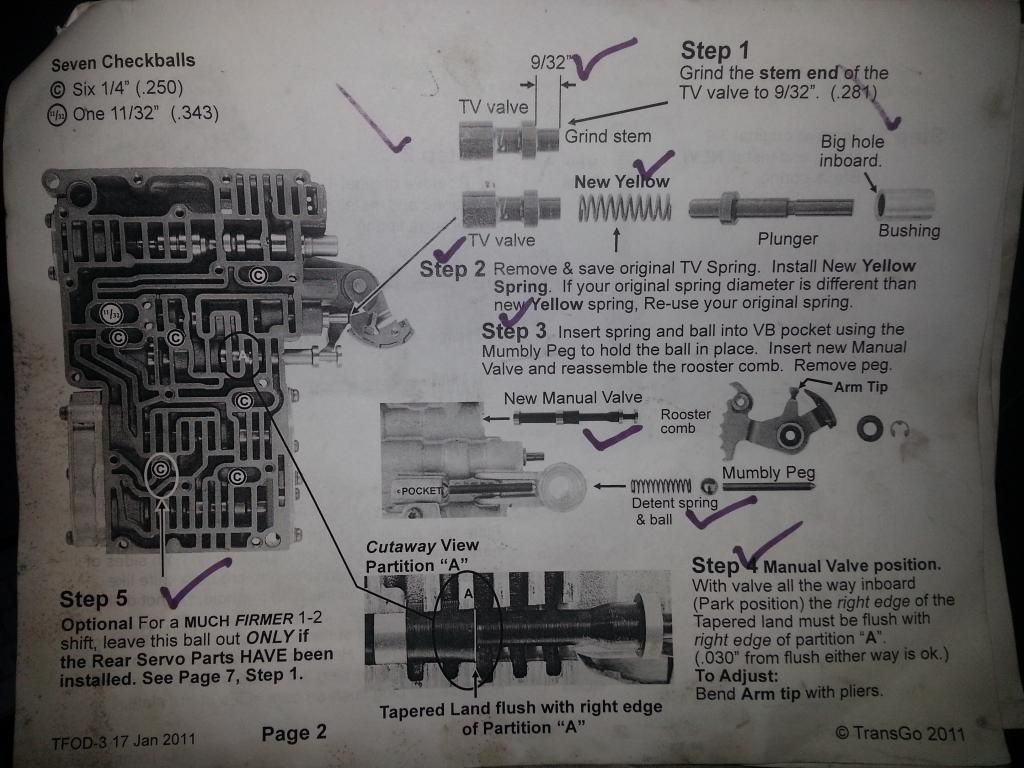

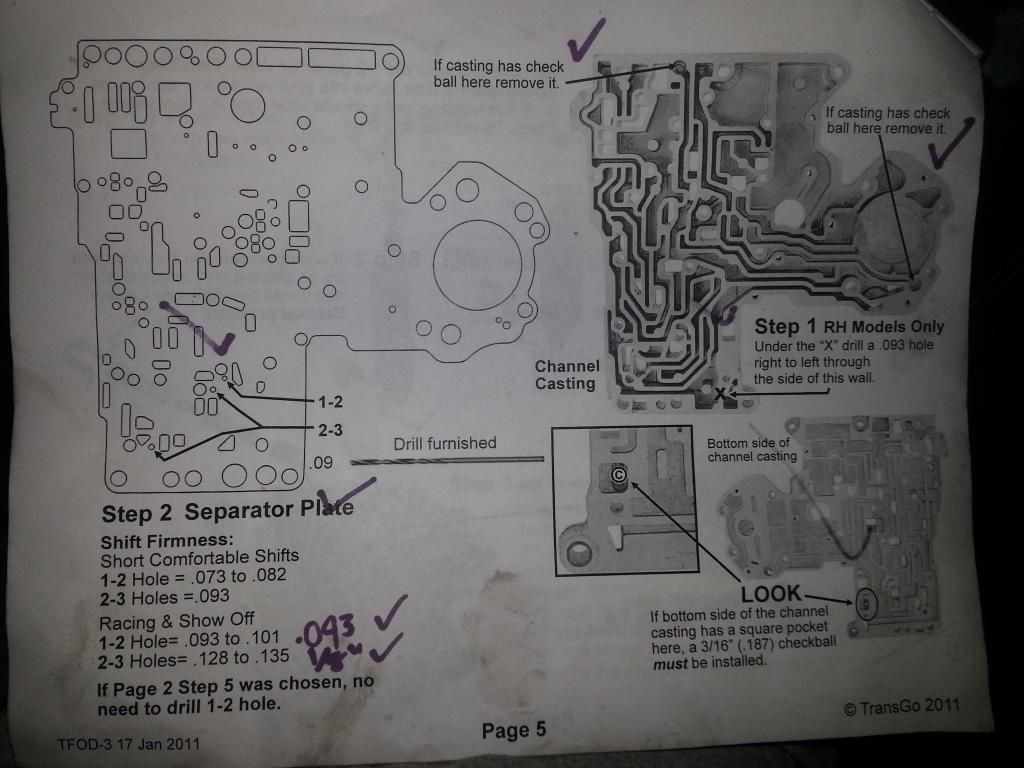

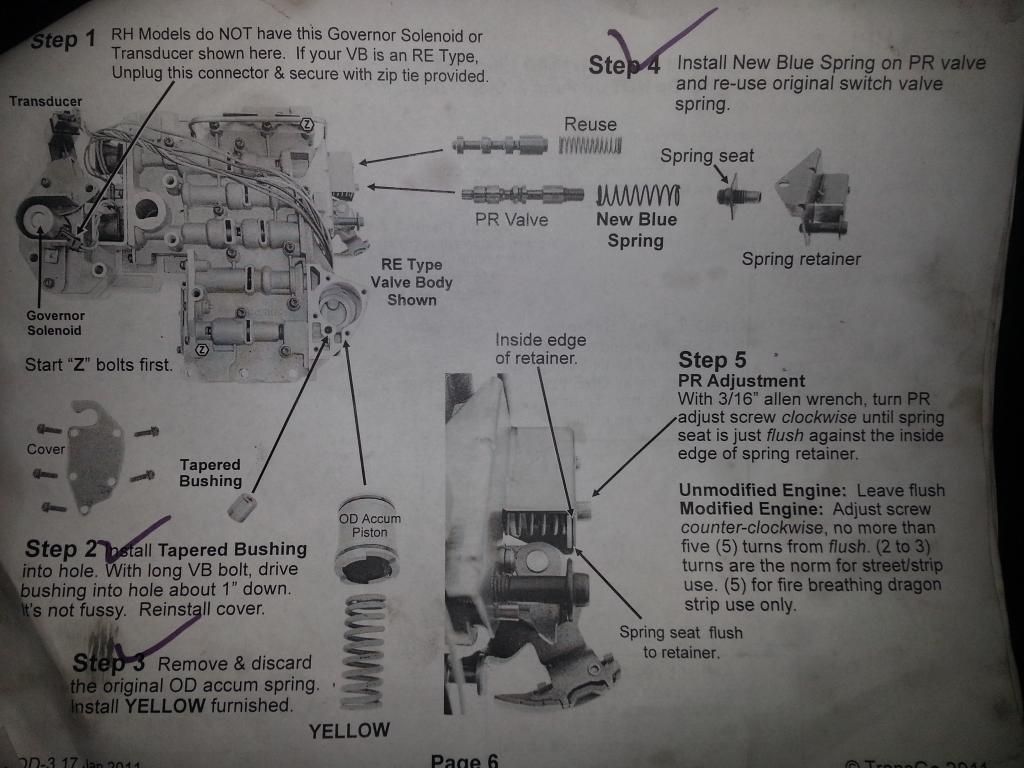

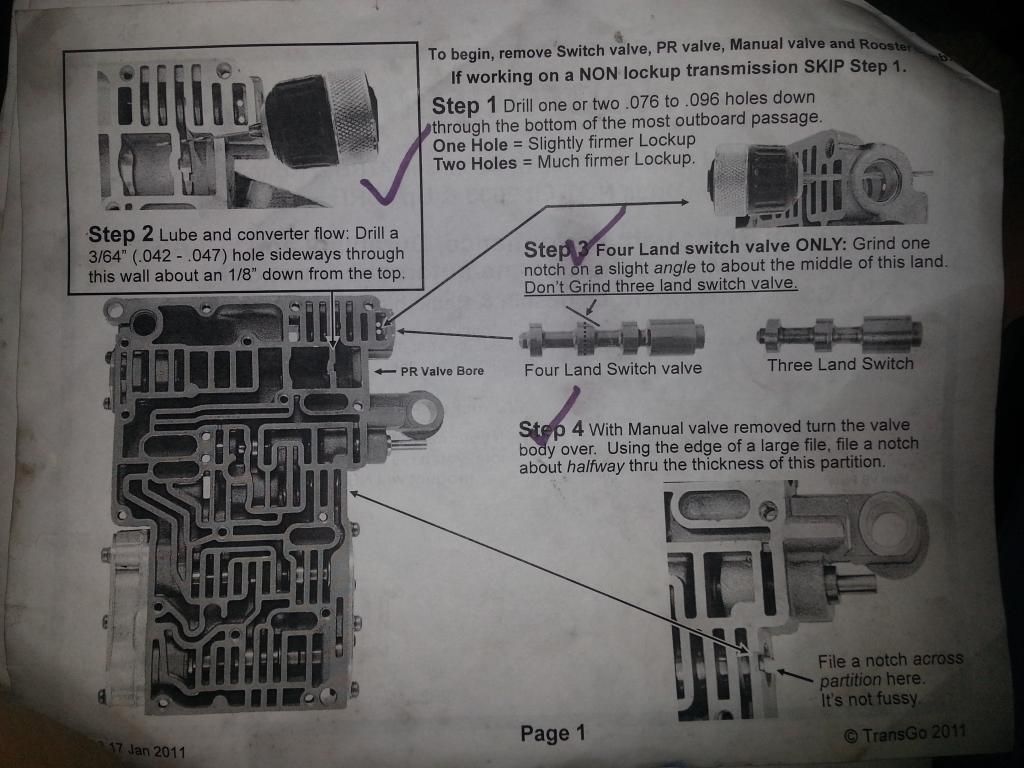

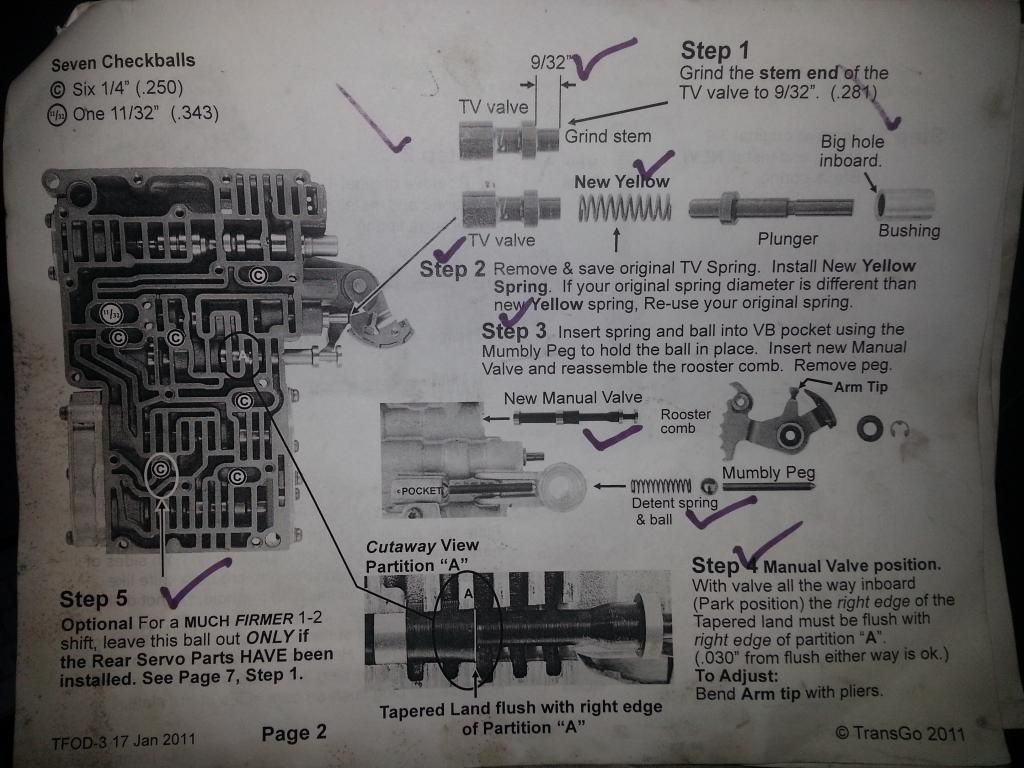

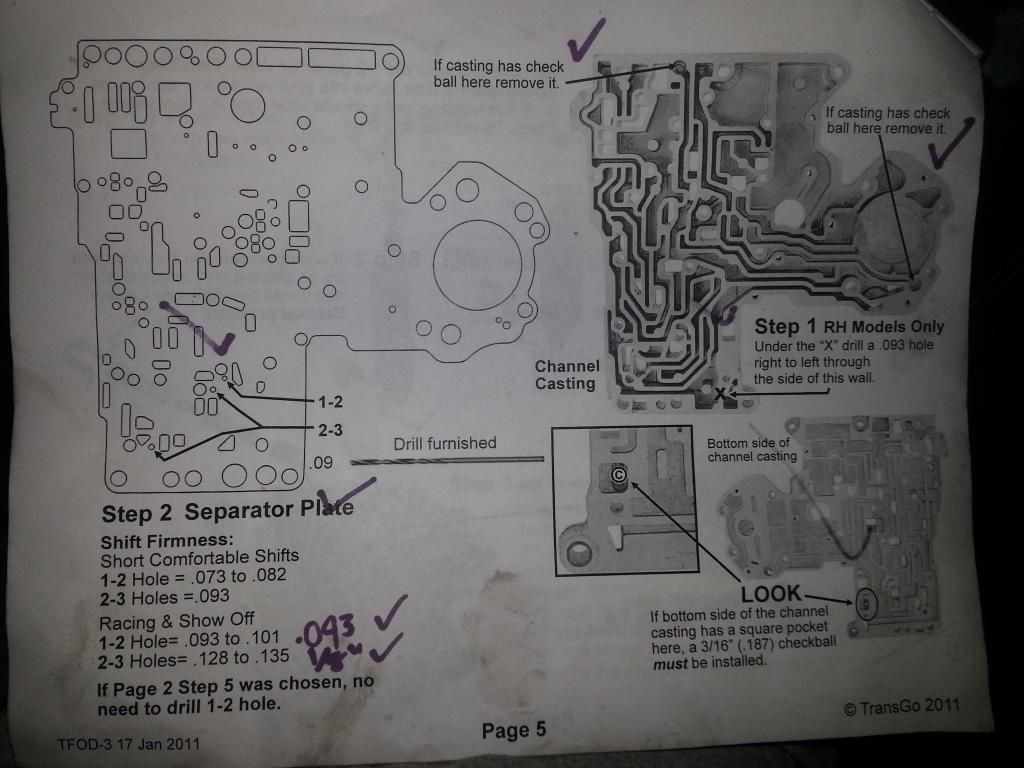

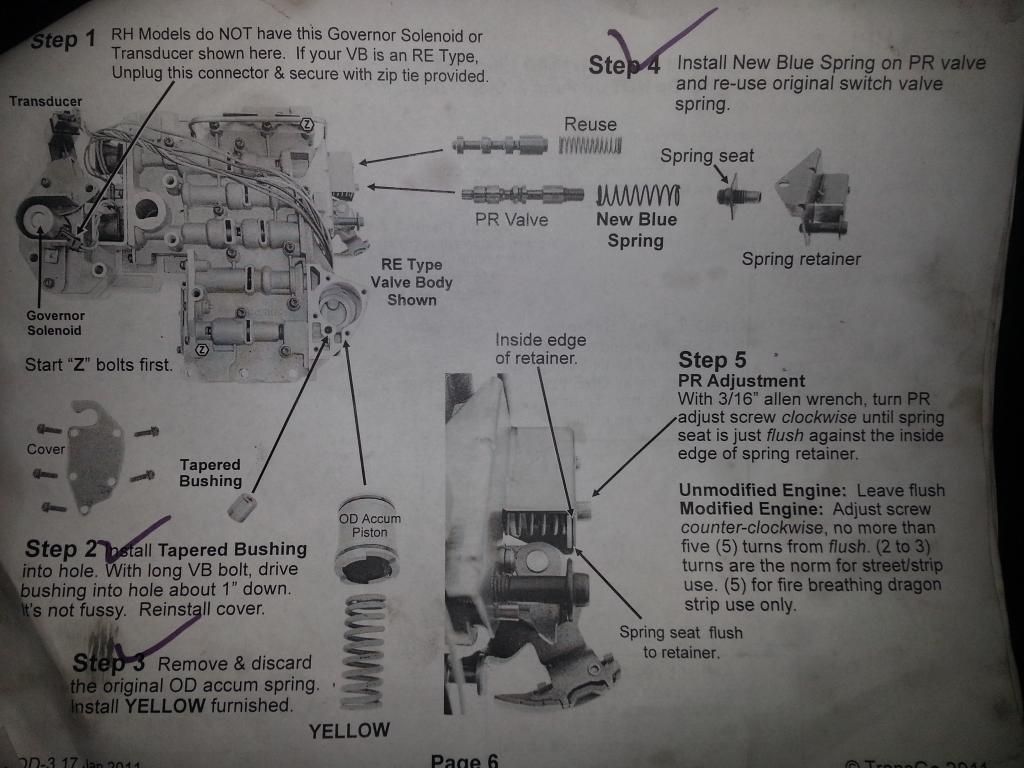

Installing the Trans Go kit is pretty straight forward, just follow the directions and you shouldnt have any issues. However i recommend drilling the holes they instruct you to, to the biggest size they state in the instructions. Your also required to grind three things. I used my bench top grinder and it was a piece of cake. The rest is swapping springs and such.

Here is the drilling and grinding required, ignore the sharpie writing...

Second gear lockup, fill this passage with jb weld and level it off with a razor before it cures all the way.

http://www.cumminsforum.com/forum/9...-engine/580571-2nd-gear-automatic-lockup.html

Here is 1st gear lockup if you want it, i didnt so if someone drives my truck it will automatically unlock on the downshift to first and not stall out.

The instructions say to not take this PR bolt past 5 turns, this is line pressure. I tried 5 turns and had the tv arm set wide open. This does NOT work, it causes a 2-3 shift issue. You have to set the tv arm at about 80%, and turn the line pressure bolt up to almost the halfway point. This gave me about 180psi constant pressure and no shifting issues, you may need to drop the pan to adjust it for your application but thats life. Here is where you check line pressure

You can leave or remove your tv cable or motor, and the same with your column shifter and linkage. I chose to remove mine. Unbolting both at the transmission was a piece of cake, next is onto the steering column to remove the shifter.

This is the location of the shifter, you will need to remove the panel under the steering wheel for room

This is the one bolt on the backside that you need to remove to pull the shifter, may help to take the plastic off around the steering column to reach the screw.

Next up is wiring for the valve body. Because of the way my shifter linkage was setup, i had to do away with the Neutral Safety Switch that plugs into the transmission. I filled the hole with a plug and ultra black rtv like pictured below. However that box contains the NSS wire which must be grounded for the vehicle to start. I grounded mine to the trans so it will start in any gear. You may hook this up to your shifters nss or do the same as i did.

Plugged NSS hole......

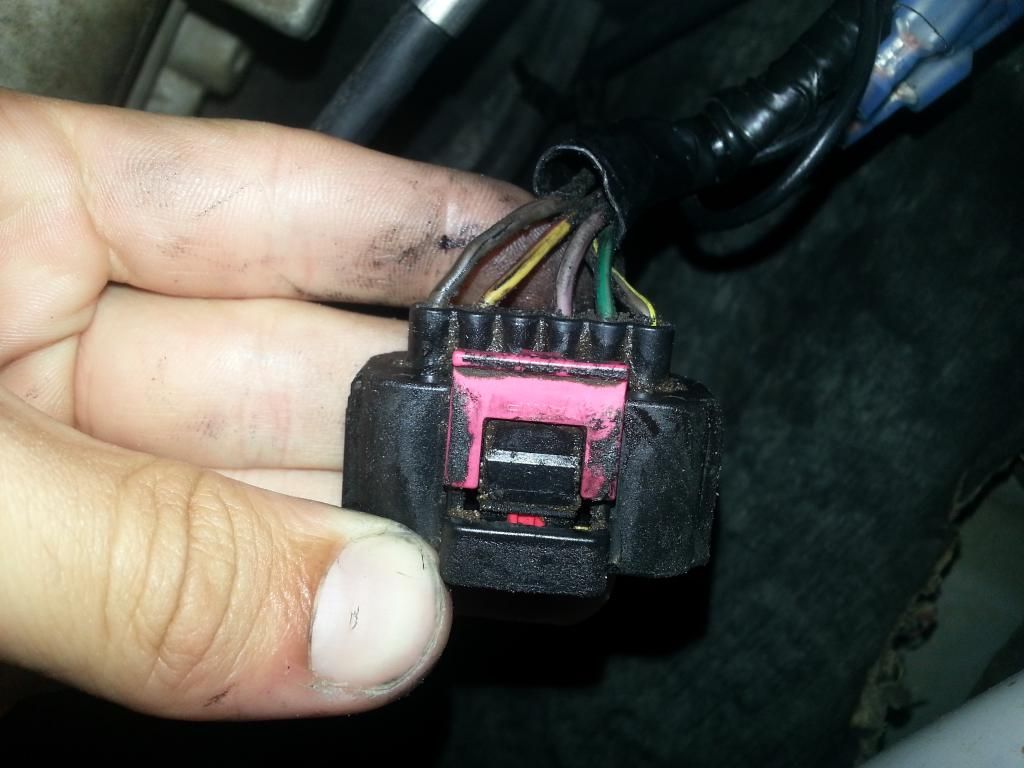

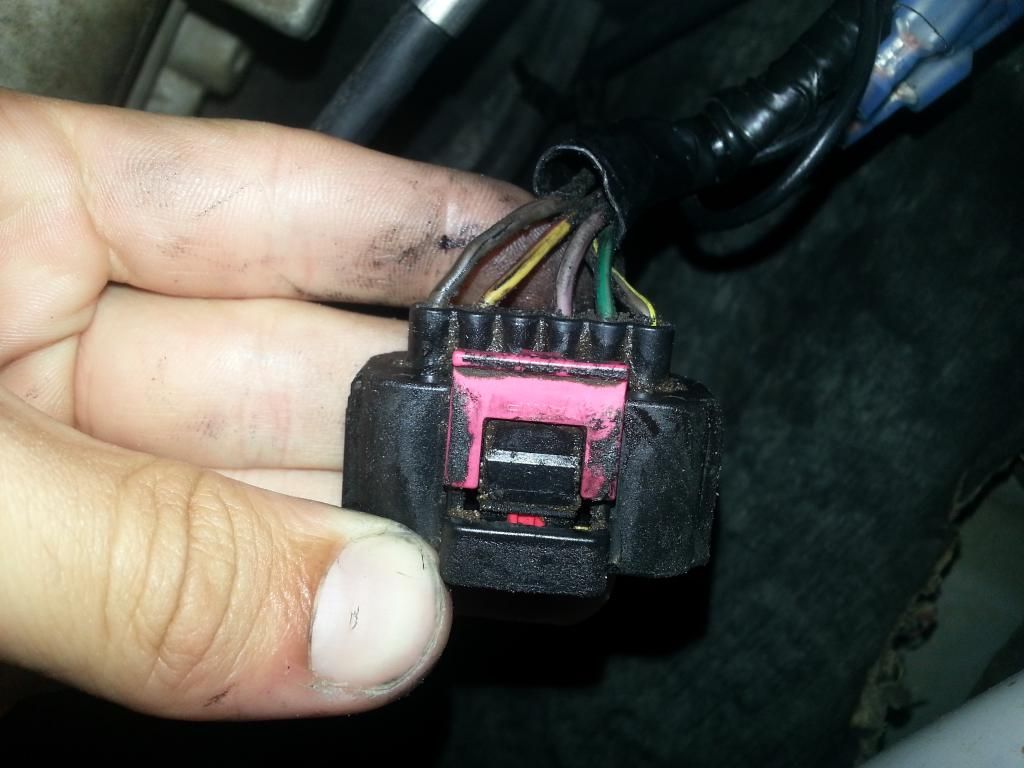

This is the NSS plug which will no longer will connect to anything but we need to hookup 3 wires to it. The far right wire pictured(br/yl) is the neutral safety switch wire that must be grounded or hooked up to a switch to start. The middle(pur/bk) and far left(brown) must be hooked up to a switch or other device to control your reverse/backup lights. One wire into the switch, the other out the switch, simple as that.

Next up is a 12v source, torque converter ground, and overdrive ground.

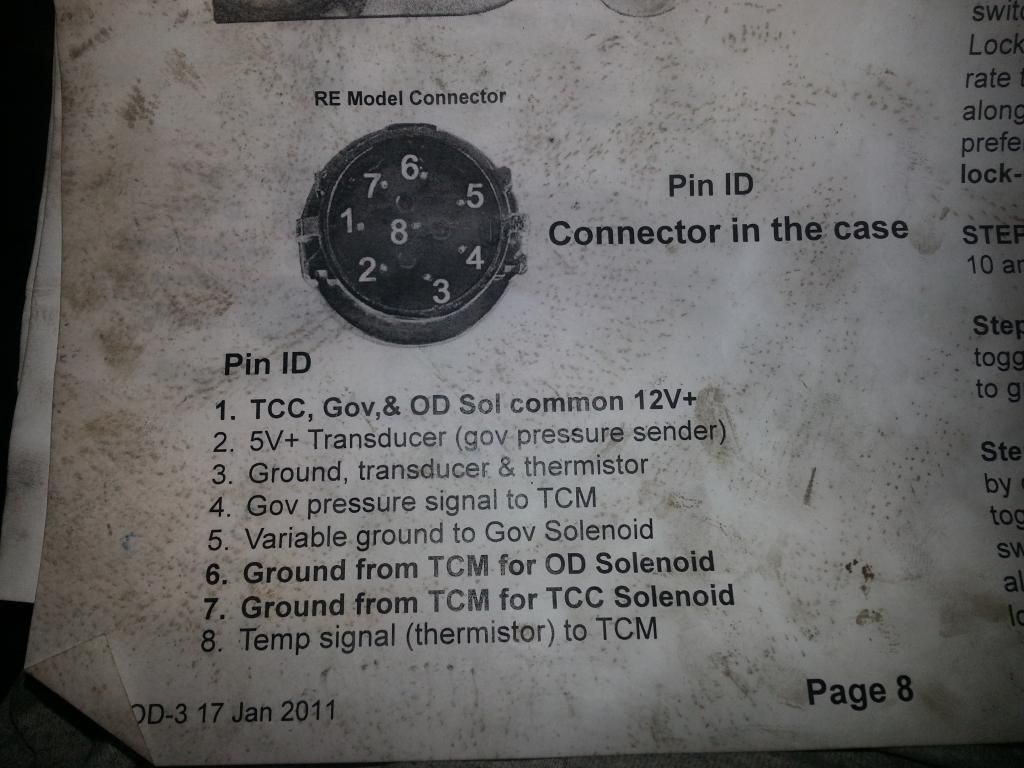

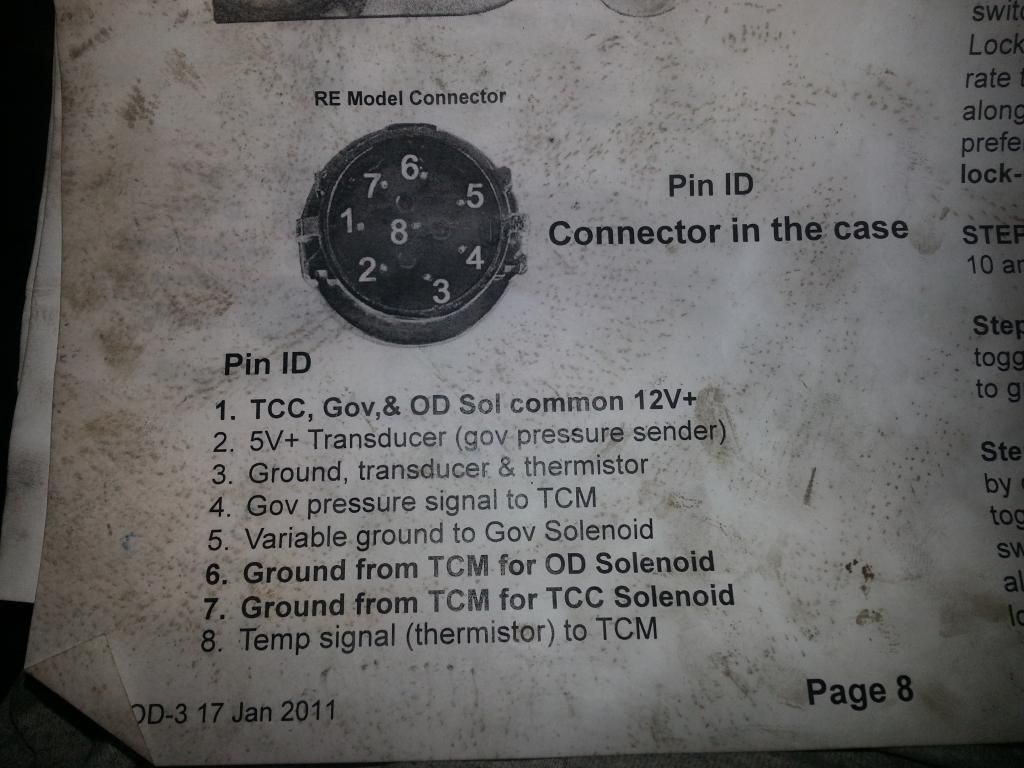

Obviously tc and overdrive are easy, just run a wire to a switch, the ground on the other side of the switch. The plug at the transmission has a red 12v wire that will show voltage with the key on, but once running the engine the pcm will cut off that voltage because it thinks the transmission is having an error because its not getting feed back from sensors. So you need to hookup a KEY-on 12v to feed the red wire which is Pin #1. If you look closely on the face of the plug it shows the pin numbers. See plug pinout below

Lockup and OD Indicator led's

Last part is the shifter install, im not going through my install because it is a 100% personal preference on how you want it setup. BUT I WILL SAY, after using the Cheetah shifter there is no way i would have been happy with a ratchet type shifter!! Trust me on that one. Anyway heres my setup, still working on the mount and have to build my sheet metal box around it to mount switches and make for a clean install. The 4x4 floor shifter will still be functional and ill post pics when im done building it. Its in a super comfortable spot that feels natural to drive.

Heres what i used:

-Trans Go TFOD-3 manual valve body kit

-a 46re valve body, yes a 46re will also work just fine

-Turbo Action SCS Cheetah shifter

-some misc electrical connectors and wires

-sockets, screw drivers, a bench top grinder, drill

MAKE SURE TO BLOCK THE TRUCK SO IT WONT ROLL, YOU WILL BE UNHOOKING THE PARKING ROD IN THE TRANSMISSION!!!!!!!

Removing the valve body is straight forward, remove shifter linkage and tv motor or cable, drain the oil, remove the pan and filter, remove all the 11mm valve body bolts except for one or two to hold it up while you remove the parking rod c clip. C clip is located on the underside of where my finger tip is, use a long flat head screwdriver to pop it off then pull the valve body out

Installing the Trans Go kit is pretty straight forward, just follow the directions and you shouldnt have any issues. However i recommend drilling the holes they instruct you to, to the biggest size they state in the instructions. Your also required to grind three things. I used my bench top grinder and it was a piece of cake. The rest is swapping springs and such.

Here is the drilling and grinding required, ignore the sharpie writing...

Second gear lockup, fill this passage with jb weld and level it off with a razor before it cures all the way.

http://www.cumminsforum.com/forum/9...-engine/580571-2nd-gear-automatic-lockup.html

Here is 1st gear lockup if you want it, i didnt so if someone drives my truck it will automatically unlock on the downshift to first and not stall out.

The instructions say to not take this PR bolt past 5 turns, this is line pressure. I tried 5 turns and had the tv arm set wide open. This does NOT work, it causes a 2-3 shift issue. You have to set the tv arm at about 80%, and turn the line pressure bolt up to almost the halfway point. This gave me about 180psi constant pressure and no shifting issues, you may need to drop the pan to adjust it for your application but thats life. Here is where you check line pressure

You can leave or remove your tv cable or motor, and the same with your column shifter and linkage. I chose to remove mine. Unbolting both at the transmission was a piece of cake, next is onto the steering column to remove the shifter.

This is the location of the shifter, you will need to remove the panel under the steering wheel for room

This is the one bolt on the backside that you need to remove to pull the shifter, may help to take the plastic off around the steering column to reach the screw.

Next up is wiring for the valve body. Because of the way my shifter linkage was setup, i had to do away with the Neutral Safety Switch that plugs into the transmission. I filled the hole with a plug and ultra black rtv like pictured below. However that box contains the NSS wire which must be grounded for the vehicle to start. I grounded mine to the trans so it will start in any gear. You may hook this up to your shifters nss or do the same as i did.

Plugged NSS hole......

This is the NSS plug which will no longer will connect to anything but we need to hookup 3 wires to it. The far right wire pictured(br/yl) is the neutral safety switch wire that must be grounded or hooked up to a switch to start. The middle(pur/bk) and far left(brown) must be hooked up to a switch or other device to control your reverse/backup lights. One wire into the switch, the other out the switch, simple as that.

Next up is a 12v source, torque converter ground, and overdrive ground.

Obviously tc and overdrive are easy, just run a wire to a switch, the ground on the other side of the switch. The plug at the transmission has a red 12v wire that will show voltage with the key on, but once running the engine the pcm will cut off that voltage because it thinks the transmission is having an error because its not getting feed back from sensors. So you need to hookup a KEY-on 12v to feed the red wire which is Pin #1. If you look closely on the face of the plug it shows the pin numbers. See plug pinout below

Lockup and OD Indicator led's

Last part is the shifter install, im not going through my install because it is a 100% personal preference on how you want it setup. BUT I WILL SAY, after using the Cheetah shifter there is no way i would have been happy with a ratchet type shifter!! Trust me on that one. Anyway heres my setup, still working on the mount and have to build my sheet metal box around it to mount switches and make for a clean install. The 4x4 floor shifter will still be functional and ill post pics when im done building it. Its in a super comfortable spot that feels natural to drive.