Can you get the oil pan off with the motor in a two wheel drive. I've got a noise in the motor after the last time I put it together we can't figure out. I would like to pull the oil pan to have a look at the bearings. The cylinder walls and pistons looked good from the top. It mixed the oil and water bad and got a little hot before I got it shut down. I've drove it around 350 miles since the last retorque. Just held 65 lbs. of boost before a boot slipped of. The sound doesn't change much maybe a hair deeper under load. I'm thinking the antifreeze water might have hurt a bearing. Hoping to pull the pan and maybe roll bearings in it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

oil pan

- Thread starter gwhammy

- Start date

12vriviera

That Guy with that car

- Joined

- Mar 31, 2009

- Messages

- 6,846

You can, loosen up motor mounts, and cab mounts, lift cab a bit raise motor, and pan will wiggle out.

pic_jon

$5 Fine For Whinin'

- Joined

- Jun 9, 2011

- Messages

- 416

Once you get all the oil pan bolts out, it'll drop a few inches, that will allow you to remove the 3-4 bolts holding the pickup tube making it easier on ya.

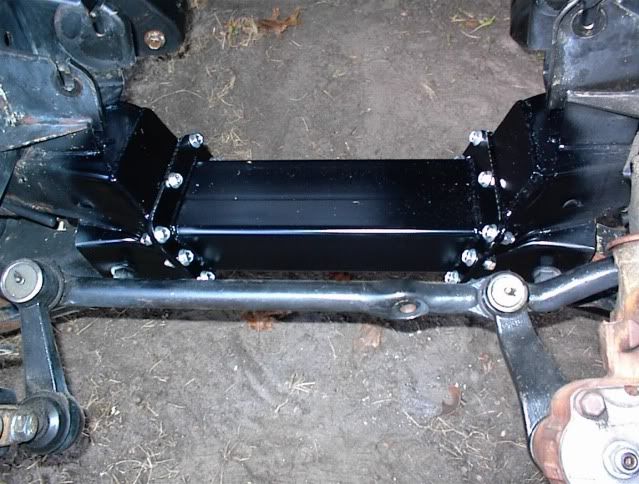

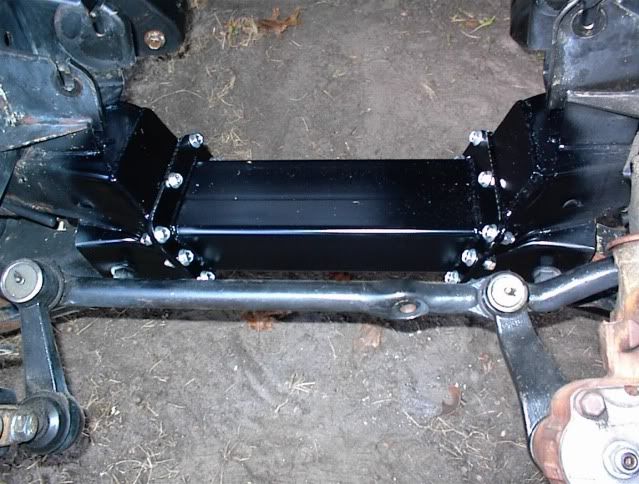

Some people slice the center crossmember out from under the oil pan. They box the ends and fab up tabs to make it bolt on/removable. I'll probably do that if I take the pan off again.

Some people slice the center crossmember out from under the oil pan. They box the ends and fab up tabs to make it bolt on/removable. I'll probably do that if I take the pan off again.

Thanks, slicing the crossmember on a two wheel drive might be hard, I could see doing that on a four wheel drive though. I would really like to fix this without pulling the motor. Next truck I'm going about this hot rod sh!t a little different.

golfersmith

New member

- Joined

- Jun 22, 2007

- Messages

- 611

It will come out, removing the 5-6 valve covers, fan shroud, mounts, hood, etc. Lift engine, remove bolts, lower pan, remove oil pump pick up tube bolts. Patience will help also. I don't ever recommend slicing, modifying, any support member jeporidizing the integrity of the frame.

renopker

New member

- Joined

- Dec 22, 2007

- Messages

- 514

Thanks, slicing the crossmember on a two wheel drive might be hard, I could see doing that on a four wheel drive though. I would really like to fix this without pulling the motor. Next truck I'm going about this hot rod sh!t a little different.

I did it this way just in case.

2000_fummins

jack of all master of few

- Joined

- Sep 3, 2011

- Messages

- 1,196

I did it this way just in case.

Thats awesome. You could damn near do a whole motor build in truck. Has anyone done this on a ford with a cummins conversion?

golfersmith

New member

- Joined

- Jun 22, 2007

- Messages

- 611

That is some awesome fabrication.

That is a nice crossmember, I'm not planning on doing this but once so we will try to do it by raising it. I've got a friend with a shop doing it on a hoist which will help alot. Pulling it wed. so I ought to know how bad I screwed up this time.

pic_jon

$5 Fine For Whinin'

- Joined

- Jun 9, 2011

- Messages

- 416

That is a nice crossmember, I'm not planning on doing this but once so we will try to do it by raising it. I've got a friend with a shop doing it on a hoist which will help alot. Pulling it wed. so I ought to know how bad I screwed up this time.

:Cheer: I hope it goes as planned!

madmikeismad

So mad

- Joined

- Dec 19, 2009

- Messages

- 14,347

I just loosened motor mounts, and hoisted the motor up about 4 inches. Gave me plenty of room to wiggle it out.

golfersmith

New member

- Joined

- Jun 22, 2007

- Messages

- 611

Did you remove the rear valve covers too?

madmikeismad

So mad

- Joined

- Dec 19, 2009

- Messages

- 14,347

Did you remove the rear valve covers too?

Yeah, gives you a couple more inches to play with. And I was doing cam swap at the time.

Worked like a charm, had to take the hot pipe off of the 351 and got it up enough to stick bolts threw the motor mount holes under the motor mounts to hold it up.

Found some hard metal that looks like it was cut with drill bit, long and short slivers fairly hard metal. Also one oring about 5/8 to 3/4 accross cut in one spot in the pan. I only got to pull one rod bearing down and it looked great. We are going to pull each one and spin the top ones out to look at them.

We were wondering if these shavings could be off of the thrust bearing? Just a thought will find out tomorrow.

One question, are the rod bolts reuseable? I'll do a search but if someone has that knowledge would you post it on here please.

All the cylinder walls looked real good that I could see we'll get a better look at them tomorrow when we roll the motor over.

Found some hard metal that looks like it was cut with drill bit, long and short slivers fairly hard metal. Also one oring about 5/8 to 3/4 accross cut in one spot in the pan. I only got to pull one rod bearing down and it looked great. We are going to pull each one and spin the top ones out to look at them.

We were wondering if these shavings could be off of the thrust bearing? Just a thought will find out tomorrow.

One question, are the rod bolts reuseable? I'll do a search but if someone has that knowledge would you post it on here please.

All the cylinder walls looked real good that I could see we'll get a better look at them tomorrow when we roll the motor over.

Last edited: