The good part about Greg’s manifold is that, if a problem should arise, the entire program evolves. This is part of the sport and part of being out front. Greg has fixed problems immediately. This is why he has hundreds of satisfies customers on these manifolds and his heads.

Greg spends many hours doing flow work on his in-house flow bench; I spend a lot of time on his flow bench as well.

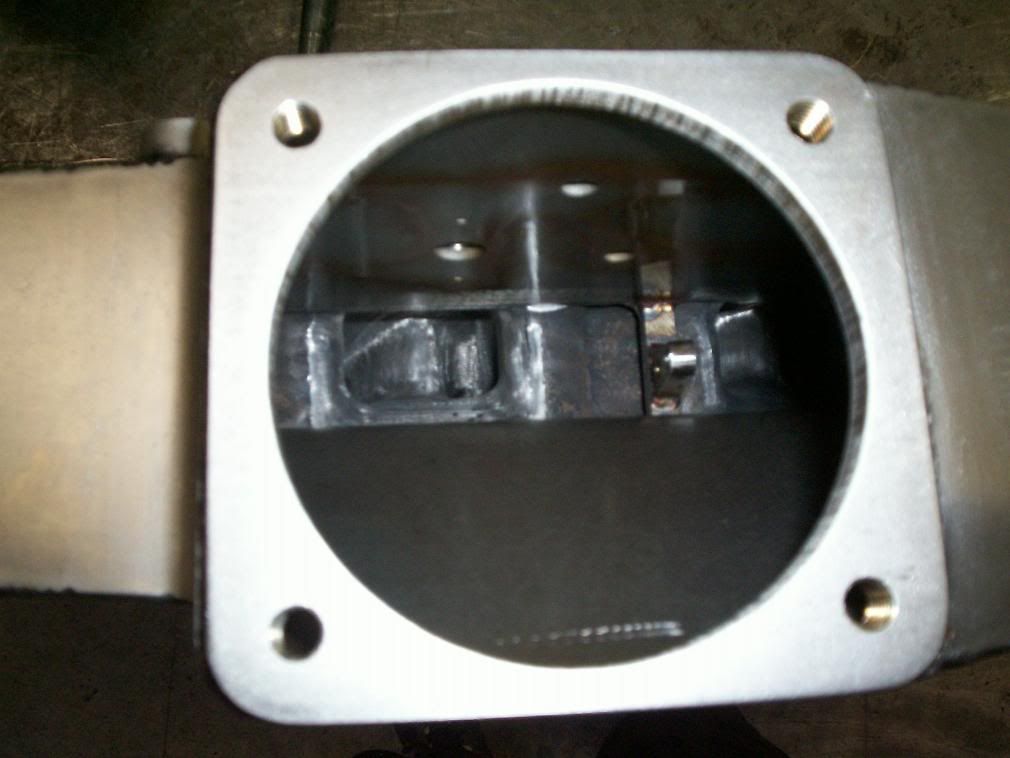

The problems with the billet style manifolds is they were designed to just be large enough, without addressing the airflow on the front and rear port. If you made the plenum large enough to service the front and rear port, the manifold would be a much larger manifold, and start with a lot bigger chunk of billet material, making the cost prohibitive.

After flowing the front and rear port , with both the Billet manifold and Greg’s Side draft , the results are very revealing, with a definite restriction on the billet manifold in flow numbers of 5 cfm on the front port, and 7 cfm on the rear port. This is from a single valve open for just that port, where the total port flow was 121 on the front, and 117 cfm on the rear.

Greg builds each manifold for the individual customers needs, being able to customize it to a individuals particular need. This is a big benefit