2wpuller

letting the smoke fly

- Joined

- Dec 27, 2006

- Messages

- 2,894

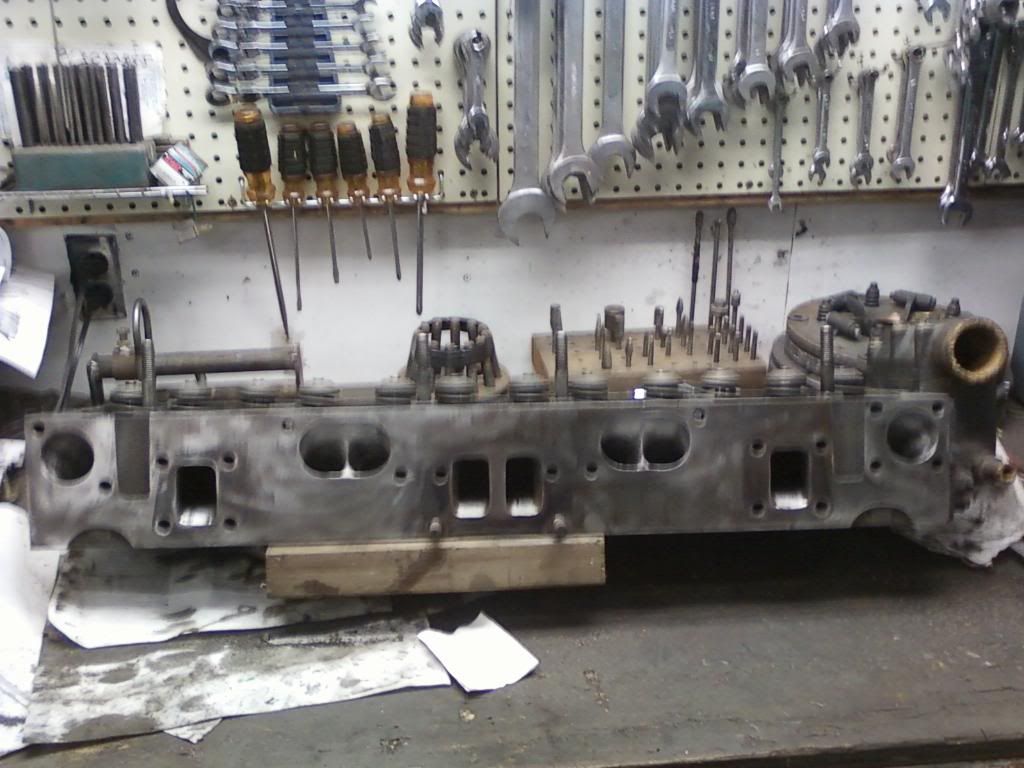

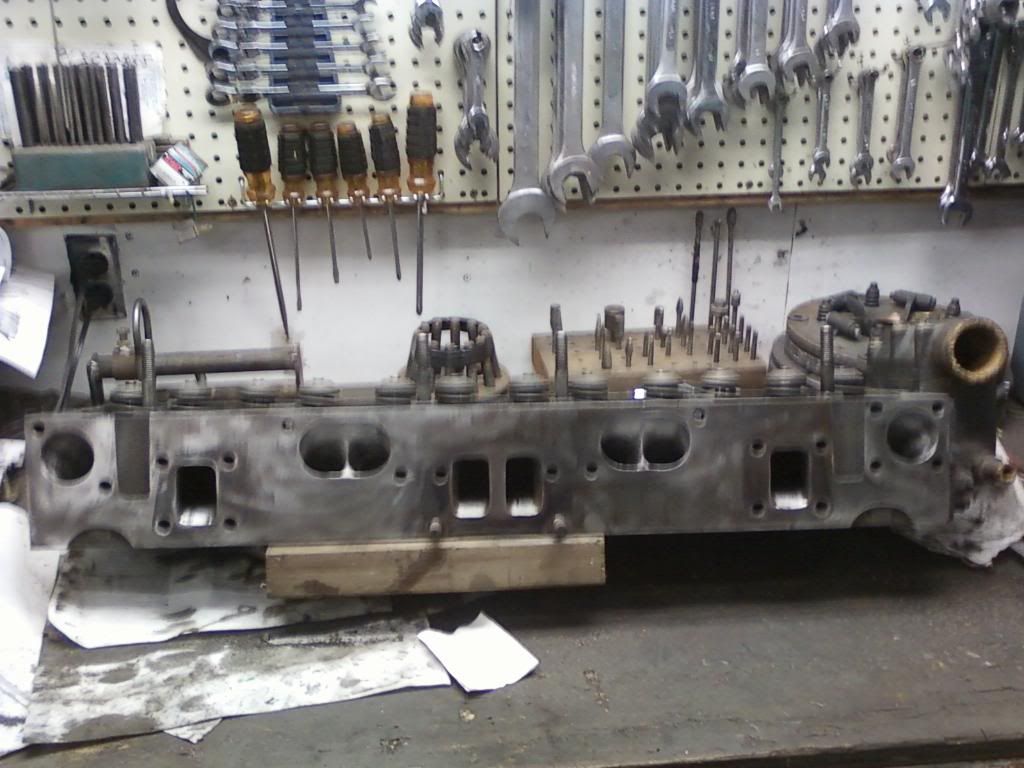

Intake valve size is 1.766 and the exhaust 1.477

What is your opinion the port versus the 5.9.The valve lift is the same on int.and exh. .441 stock cam.comp.ratio is 17.5. bore is 3.937 stroke is 5.0.befor and after pic.of the ports only port matched and cleaned up the castings inside of them.What do you think the intake will flow.

Ehx.before matching to manifold.

after matching.

Intake manifold didn't have to doeny grinding on it.

Intake ports before.

After grinding.intake.

This a pic compareing the 5.9 and the perkins piston,rod,the piston look almost the same.

Dale

What is your opinion the port versus the 5.9.The valve lift is the same on int.and exh. .441 stock cam.comp.ratio is 17.5. bore is 3.937 stroke is 5.0.befor and after pic.of the ports only port matched and cleaned up the castings inside of them.What do you think the intake will flow.

Ehx.before matching to manifold.

after matching.

Intake manifold didn't have to doeny grinding on it.

Intake ports before.

After grinding.intake.

This a pic compareing the 5.9 and the perkins piston,rod,the piston look almost the same.

Dale

Last edited: