You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rail Pressure Gauge

- Thread starter Buck1

- Start date

Dan@PPE

Comp Diesel Sponsor

- Joined

- Aug 12, 2006

- Messages

- 148

We have them in stock. Pm me or email me dan@pacificp.com

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

A gauge is better then nothing at all, but the real knowledge is the trends that happen in conjunction with and correlated to other actions and measurements.

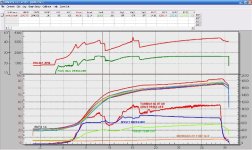

I have proven beyond a doubt that when people preach they are “draining the rail “that this is erroneous. The screen print below is at the 928 hp tunes on project X this shows that with one Industrial Injection stage II CP3 pump that at this hp setting the rail is still at 26,500 lbs of pressure.

Knowledge is the key to making power; I absolutely believe that if you don’t have a data logger, you are running blind. Can you make power and run good with out one, the answer is yes you can, but you can run much with a data Logger.

RPM PRO Software

• 3 RPM CHANNELS, Engine, Clutch, Driveline or Wheel Speed

• 1 ACCELEROMETER CHANNEL, Forward G Meter , sensor extra

• 4 ANALOG CHANNELS, for Pressures, temps, position, Lateral G Meter, etc.

• 3 DIGITAL CHANNELS, for WOT, N2O Stages, etc.

• 1 BATTERY VOLTAGE CHANNEL (Internal)

1 Hall sensor

1 Pinion Collar, 4 magnets

Remote start cable and switch

All sensor cables

$ 588.00

Diesel rpm pick up $ 75.00

Rail pressure interface $ 30.00

Total $ 693.00

This will give you engine rpm, drive shaft rpm, rail pressure, and got 30 additional dollars you can monitor rail pressure out of you pressure box also, this is some interesting info.

Now that a basic system,

Add boost pressure and drive pressure for $ 136 each and. one egt’s for $ 160

Total for that system combined cost of $1118 .70 this is the minimum I would use

For $1895 you get the best of the best with 6 egt’s temps in and out of the intercooler

I have proven beyond a doubt that when people preach they are “draining the rail “that this is erroneous. The screen print below is at the 928 hp tunes on project X this shows that with one Industrial Injection stage II CP3 pump that at this hp setting the rail is still at 26,500 lbs of pressure.

Knowledge is the key to making power; I absolutely believe that if you don’t have a data logger, you are running blind. Can you make power and run good with out one, the answer is yes you can, but you can run much with a data Logger.

RPM PRO Software

• 3 RPM CHANNELS, Engine, Clutch, Driveline or Wheel Speed

• 1 ACCELEROMETER CHANNEL, Forward G Meter , sensor extra

• 4 ANALOG CHANNELS, for Pressures, temps, position, Lateral G Meter, etc.

• 3 DIGITAL CHANNELS, for WOT, N2O Stages, etc.

• 1 BATTERY VOLTAGE CHANNEL (Internal)

1 Hall sensor

1 Pinion Collar, 4 magnets

Remote start cable and switch

All sensor cables

$ 588.00

Diesel rpm pick up $ 75.00

Rail pressure interface $ 30.00

Total $ 693.00

This will give you engine rpm, drive shaft rpm, rail pressure, and got 30 additional dollars you can monitor rail pressure out of you pressure box also, this is some interesting info.

Now that a basic system,

Add boost pressure and drive pressure for $ 136 each and. one egt’s for $ 160

Total for that system combined cost of $1118 .70 this is the minimum I would use

For $1895 you get the best of the best with 6 egt’s temps in and out of the intercooler

Attachments

JOHNBOY

ZF6 Sled Puller

- Joined

- Feb 1, 2007

- Messages

- 1,854

EFI Live for $750 will nicely datalog rail pressure, timing, shot size, and lots of other stuff plus allow you tune custom tune your ECM. Expansion modules can be had that will let you log multiple egts, pressures, rpms and so for far less.

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

The difference in using a tuner and a true full function Data logger is the ability to save this data and overlay it on to different runs, The RPM computer will save between 5 and 15 runs depending on size. I also like to watch the drive line rpm in correlation to the accelerometer

JOHNBOY

ZF6 Sled Puller

- Joined

- Feb 1, 2007

- Messages

- 1,854

I cant do that?

EFI Live V2 can do all of that. You will need some expansion modules. But I just recently found out where to get them! The accelerometer I do not know. I was going to purchase a RPM pro setup but learned that I can do all I want and then some with the EFI Live I allready had.:rockwoot:

EFI Live V2 can do all of that. You will need some expansion modules. But I just recently found out where to get them! The accelerometer I do not know. I was going to purchase a RPM pro setup but learned that I can do all I want and then some with the EFI Live I allready had.:rockwoot:

duratothemax

duhhh

- Joined

- Aug 25, 2006

- Messages

- 291

COMP461 said:The difference in using a tuner and a true full function Data logger is the ability to save this data and overlay it on to different runs, The RPM computer will save between 5 and 15 runs depending on size. I also like to watch the drive line rpm in correlation to the accelerometer

EFILive can do this for half the cost IMO.

you are using an EDC-16 which has a completely different set of PIDs and data readout capabilities If I am not mistaken...I could be wrong tho!

the stock delphi dmax truck ECM's can read out plenty of data. Combined with transmission logging (ISS, OSS, TIS, TCC duty cycle) and you dont need any standalone sensors for 99% of data logging on pickup trucks. If you want to add drive pressure etc guages you can input outside sources to efilive as well...

just my oppinion

ben

LarryJewell

<<<<<<<<

- Joined

- Mar 29, 2007

- Messages

- 35

I have scan gauges, they display, Iat's, ect's, rail pressure, desired rail pressure, and about 15 or so other things, basically everything that EFI scans and displays. I have them in a trippin overhead console mount. each gauge moniters 2 parameters and they plu into the obd port.