71CHEVY4x4

New member

- Joined

- Oct 23, 2008

- Messages

- 24

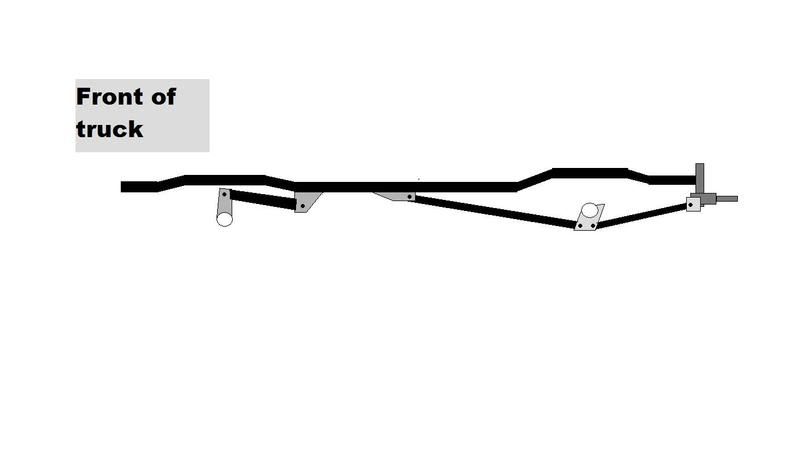

Curios if anyone here is running a suspension block that runs from the hitch to the bottom of the rear axle at a diagnol using tube and adjustable heims??

Hope that makes sense?

Alot of local guys are running this instead of the usual suspension block that is directly above the axle.

My thought is this could really help take some stress off the frame section and apply it directly to the axle which in turn applies pressure to your traction bars. It basically is a traction bar that runs from the axle back to the hitch, but limits suspension travel also?

Anyone familiar with this?

Does it work?

thanks guys

Hope that makes sense?

Alot of local guys are running this instead of the usual suspension block that is directly above the axle.

My thought is this could really help take some stress off the frame section and apply it directly to the axle which in turn applies pressure to your traction bars. It basically is a traction bar that runs from the axle back to the hitch, but limits suspension travel also?

Anyone familiar with this?

Does it work?

thanks guys