Hi.

My nick is tb205gti - because I once owned a Peugeot 205 GTI 1.6 - ahh those was the days Once you get older you (well some..) get wiser, so I have jumped the derv wagon. Since I'm not from the US, I drive a tiny car.

Once you get older you (well some..) get wiser, so I have jumped the derv wagon. Since I'm not from the US, I drive a tiny car.

It is a Peugeot 206 HDI 2.0l 8v HDI. It's a 1st gen CommonRail engine producing mahooosive 90BHp and 205Nm. When it was new Peugeot decided they would not fit an intercooler, so I have added a 8L intercooler.

Apart from the intercooler the following has been added/changed:

2nd gen. Railpressure sensor (1800bar)

Uprated Sachs clutch pressureplate, running std. friction plate.

Mitsubishi TF035 VNT turbo (From a BMW 320d, 177BHp)

Std. exhaust, added middle silencer (straight through) and straightthrouh backbox.

100 cells motorsports catalytic converter

Uprated engine mounts.

238mm grooved discs (original is 247mm)

Coilover suspension, lowered approxx. 40mm.

And finally my own custom remap, with VNT control, launchcontrol and other small very custom things.

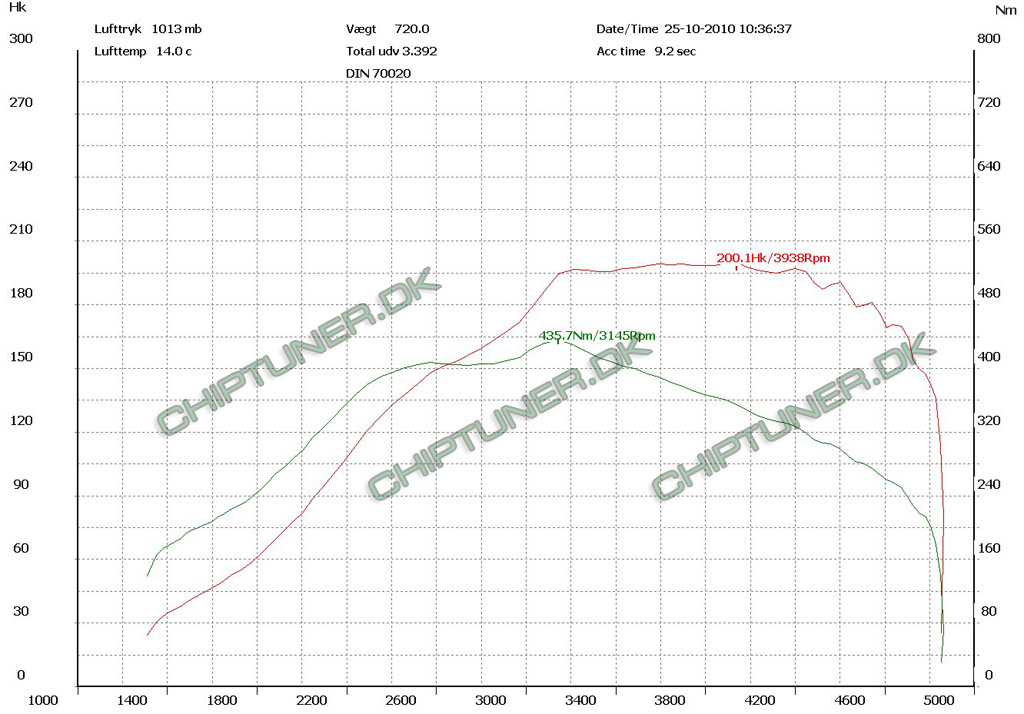

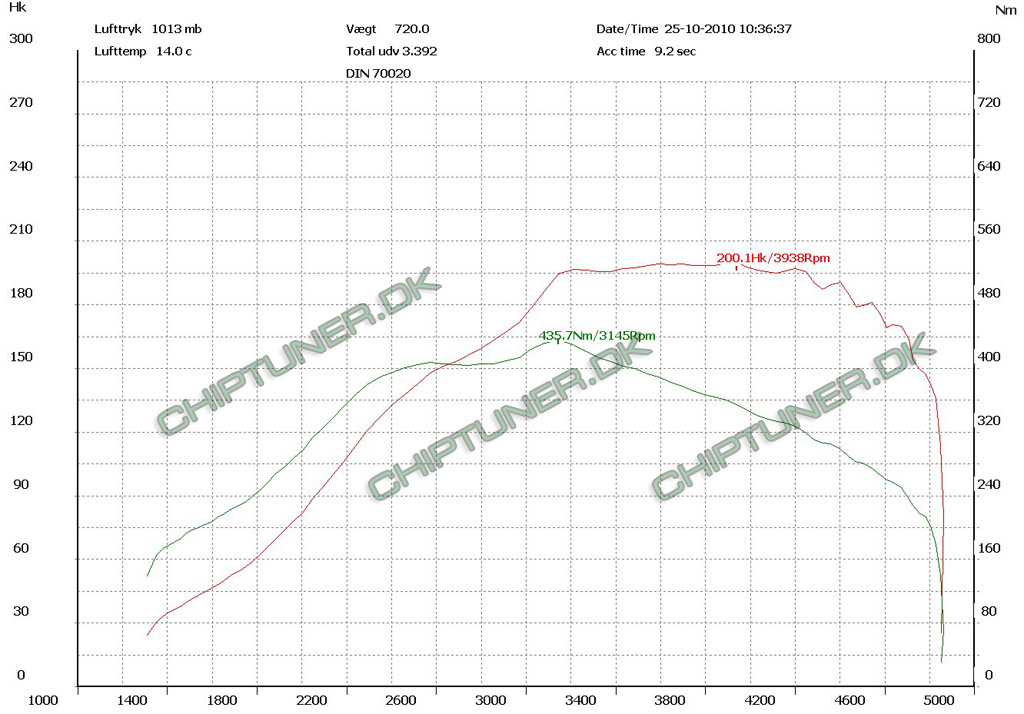

And the power - well it is not much by your standards running 6L engine, but I'm quite chuffed with it.

..and a rr session where it produced 193BHp: http://www.youtube.com/watch?v=kSfNE3DntnQ&feature=youtu.be&hd=1

Next mod is uprated pressurepipes, I use an original lower pipe that is made from plastic and only has a 38mm inside diameter. Better exhaust, I'm hopng to go stainless 2.5" with the same silencers (they are 2.5")

And then the biggest issues, my HP pump (CP1, R70) is running on it's limit right now. Any tips for getting more flow from it?

Injectors, the DW engine uses injector tips that have a unique angle, no other tip has the same angle. Bosch Motorsport will make custom tips with the right angle, but at a price of 1000 Euro a piece.. Any tips?

My nick is tb205gti - because I once owned a Peugeot 205 GTI 1.6 - ahh those was the days

It is a Peugeot 206 HDI 2.0l 8v HDI. It's a 1st gen CommonRail engine producing mahooosive 90BHp and 205Nm. When it was new Peugeot decided they would not fit an intercooler, so I have added a 8L intercooler.

Apart from the intercooler the following has been added/changed:

2nd gen. Railpressure sensor (1800bar)

Uprated Sachs clutch pressureplate, running std. friction plate.

Mitsubishi TF035 VNT turbo (From a BMW 320d, 177BHp)

Std. exhaust, added middle silencer (straight through) and straightthrouh backbox.

100 cells motorsports catalytic converter

Uprated engine mounts.

238mm grooved discs (original is 247mm)

Coilover suspension, lowered approxx. 40mm.

And finally my own custom remap, with VNT control, launchcontrol and other small very custom things.

And the power - well it is not much by your standards running 6L engine, but I'm quite chuffed with it.

..and a rr session where it produced 193BHp: http://www.youtube.com/watch?v=kSfNE3DntnQ&feature=youtu.be&hd=1

Next mod is uprated pressurepipes, I use an original lower pipe that is made from plastic and only has a 38mm inside diameter. Better exhaust, I'm hopng to go stainless 2.5" with the same silencers (they are 2.5")

And then the biggest issues, my HP pump (CP1, R70) is running on it's limit right now. Any tips for getting more flow from it?

Injectors, the DW engine uses injector tips that have a unique angle, no other tip has the same angle. Bosch Motorsport will make custom tips with the right angle, but at a price of 1000 Euro a piece.. Any tips?

Last edited: