CTD99, a set of bars installed in house will run about $350 non adjustable with all the frame and rear axle brakets welded. Adjustable bars add $200, full bolt on setups add $200.

Seeker, Adjustable suspension stops run about $150. Most of my stops just bolt to the factory Bump stop locations. Will need a few measurements on anything except dodges. I have a couple trucks I can mock them up to for a Dodge.

Not sure on a full adjustable hitch like you want just yet. Will have to come up with a few designs to see what will work the best and be cost effective. But I will get back to you on it.

Here is an e-mail I sent in reply to another person interested:

I can build any setup for mostly dodges. I do have a 02 Ford dually I can mock up some things aswell, but nothing for a D-Max as of yet on some parts.

I have found it most effective to have all the traction bar bracketry to be welded to the frame a rear axle, but I can make bolt on setups. I have also seen there is no advantage in having adjustable traction bars aswell. I do have a rear hitch bar setup that has been proven around here to very very effective. It works like the traction bar setup going from the rear axle forward, but this setup goes from the rear axle to the back of the truck near the hitch. I haven't had a chance to get any pics just yet, but I will e-mail you some as soon as i get them.

A full basic pulling setup I have includes a full slide in weight bracket made for Suit Case weights such as International, old style John Deere, Ditch Witch, ect..., Traction bar setups forward of the rear axle including bars, frame and rear axle brackets and safty cable loops, adjustable suspension stops, U-joint sheids, and an adjustable slide in hitch using a pintle hitch ring. This basic kit starts at $1200 plus shipping. This setup will be all welded bracketry aswell and the traction bars are non adjustable. Bolton setups will add $300 for U-bolts and mounting tabs.

Slide in Weight Brackets for Dodge trucks starts at $400.

Traction Bar setups start at $300 non adjustable, Adjustable bars will be an extra $200, Bolt on kits add $300.

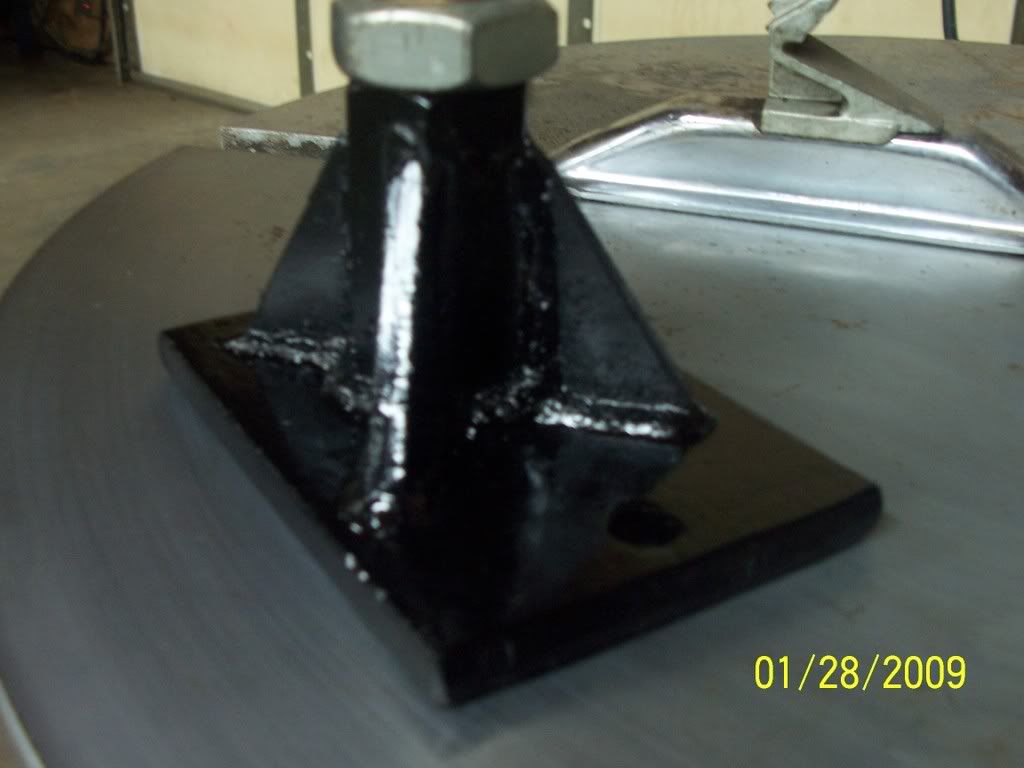

The Rear hitch bars setup for welded rear axle brackets will be $300

Full Swinging Drive Shaft Loops and U-joint Shields will be $1000 or add $600 to the above package.

Custom Reece Style hitches moved forward in the factory mounting points, slide in hitch with roll pan and sled stops are $1200- in house only

For a complete Full out Setup that includes the adjustable front traction bars, rear htich bar setup, weight bracket, suspension stops, custom hitch and roll pan package, full swinging drive shaft loops will be around $3000 installed in house. The truck will basically be a ready to go turn key chassis. Full installs usually take about a week.

Just let me know what all exactly you are wanting and also the length design of the truck (RegCab LB, ExtCab SB, ect...), and specify if the rear drive shaft is one piece or 2 piece for the drive shaft loop setups.