You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Torquing Head

- Thread starter PaulyG

- Start date

Freezingsystems

Modify Everything

- Joined

- Jan 18, 2010

- Messages

- 1,130

For all your parts Mumau Diesel Is a site vendor and Cummins Dealer. They have great prices and service is top notch. For torque procedures do a search, there is a ton of info on this.

Mumau Diesel. 724-354-3136

Mumau Diesel. 724-354-3136

kleann

VP44 pwr

- Joined

- Aug 23, 2008

- Messages

- 4,388

Enterprise Engine Performance - 12V Torque Specs Cummins Rebuild Kits

bunch of specs for stock engines.

bunch of specs for stock engines.

rattlindodge

New member

- Joined

- Jun 27, 2008

- Messages

- 507

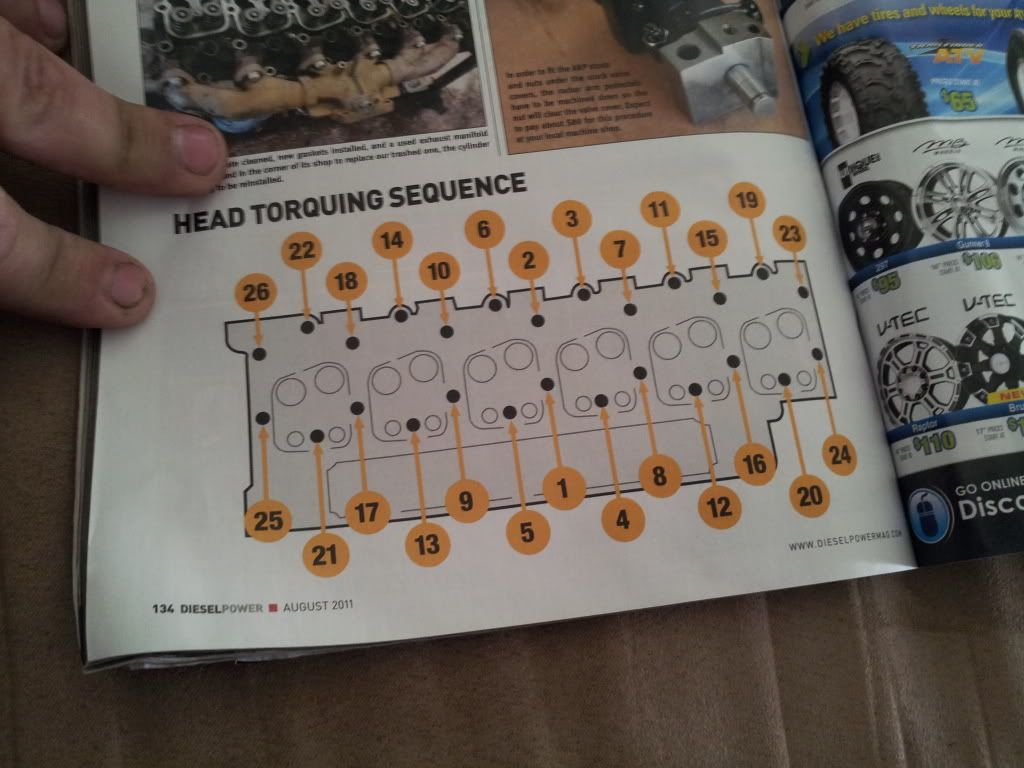

Its the typical spyder web pattern, and unless you remove each bolt and lubricate, your wasting ur time, btw the cheap arp head studs are rated for 125ft lbs.

whitneyj

still in pieces

- Joined

- Jan 31, 2012

- Messages

- 822

I did 50 - 90 and then whit small(5lb/ft) steps up to 130 lb/ft. After each step I let stand(cool down) for 15...20min. However, some bolts began to stretch out so I had to swapped them out.

What is this "stretching out" that I keep reading about?