Have plans for building a twin turbo setup for my 12v cummins.

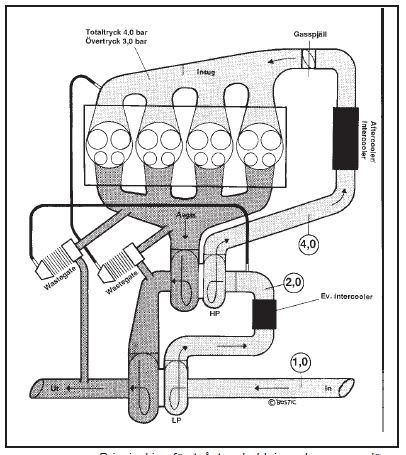

Have checked som threads and picturs, but not really seen how they are wastegated. Have seen a setup for a gasser, and they had the primary wastegated but not the secondary. But they had a external wastegate that from the manifold to the downpipe, to prevent the primary to over spinn. How shall they be adjusted to each other? Someone that can give me a fast education in twin turbo charging on cummins engine? Suggestion on turbos for about 650 hp. What material in hot pipe, pressure pipe. Bad matched turbos be twice as bad in a twin turbo setup or?

Regards From Sweden

Have checked som threads and picturs, but not really seen how they are wastegated. Have seen a setup for a gasser, and they had the primary wastegated but not the secondary. But they had a external wastegate that from the manifold to the downpipe, to prevent the primary to over spinn. How shall they be adjusted to each other? Someone that can give me a fast education in twin turbo charging on cummins engine? Suggestion on turbos for about 650 hp. What material in hot pipe, pressure pipe. Bad matched turbos be twice as bad in a twin turbo setup or?

Regards From Sweden